Change management has become its own consulting specialty. It is often part of deploying massive IT systems and some companies use change management specialists to assist in lean transformation. Unfortunately many versions are based on a flawed assumption—thinking about the transformation as what Kurt Lewin called the “unfreeze-change-refreeze” model. In his model specific actions need to be taken to get the organization ready for change, including communication programs, building consensus among senior executives, and developing reward systems. Human resources gets involved as there may be needed changes in organizational structure.

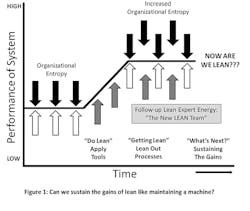

This underlying assumption of how lean transformation works is decidedly mechanistic (Figure 1).

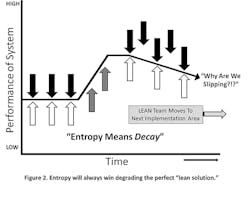

The reality is that a mechanistic approach to lean will inevitably lead to self destruction as entropy wins out (Figure 2).

When some colleagues and I were coaching a Fortune 50 company that wanted a global change to lean, they assigned human resources and communications departments to “help” with change management. Human resources wanted to develop an elaborate classroom training program and had gone through the Toyota Way building a matrix of what functions should receive what training modules. Communications was preparing an internal media campaign. My immediate reaction was “please wait. Let us get started quietly by doing at the gemba and we will call you when we are ready for some help.” I believe this turned out to be the right decision.

Lean transformation, as exemplified by the Toyota Way, is a new paradigm as The Machine that Changed the World suggested. It is much broader then a paradigm of how to set up a manufacturing facility. It is a way of thinking, and that includes thinking about change.

As many recent books have noted, people have habits and organizations have routines (cf, The Power of Habit). We are what we do that often comes from our hidden brain, as Mark Jaben deeply analyzes (http://leanleadership.guru/jaben.html). It is hidden in that we are not consciously aware of much of what goes on. In fact the most primitive parts of the brain house our most basic instincts and our deeply rooted habits.

Habits evolve through repetition and often serve a function, such as survival. Some have found that at least 40% and perhaps as much of 90% of what we do is in a sense programmed by our habitual responses. The roots of habits are invisible to us. We reason in our prefrontal cortex and believe we are at the helm controlling all of our thoughts and actions, but in reality many of our drivers are hidden deep within more primitive parts of our brain.

The problem with “change management” methods is they focus mostly on our reasoning processes. They appeal to reason, they dangle carrots and sticks, and they try to convince us logically. Since most of our habits—which at a collective level turn into organizational routines—are at the level of the hidden brain, logical arguments are doomed to fail. We can agree, we can say we agree in meetings, but mostly we will fall right back into individual habits and organizational routines.

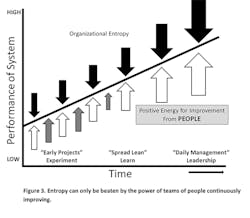

This is where the brilliance of the Toyota Production System comes in. Taiichi Ohno did little talking. He questioned, challenged and sometimes yelled, but mostly he put people in situations which changed the way they behaved on a daily basis. He broke organizational routines. The only way to beat entropy is to develop positive energy from teams of people that create a force greater then the degrading force of entropy (Figure 3).

The improvement kata developed by Mike Rother in Toyota Kata is an effective way to develop the human potential to beat entropy. It focuses at the individual level on changing our mindset from one of executing standard routines to get the job done using a scientific approach to improvement. If practiced daily, with a coach, it creates a new set of habits focused on improvement. The “learner” becomes a leader of teams focused on long-term objectives broken into short-term target conditions.

The small wins reinforce the daily behavior patterns needed to beat entropy. People can win out over entropy, but only if they learn how to do so at a deep level. Neither elaborate communication strategies nor even formal reward systems can replace daily practice to establish new, positive habits of systematic improvement.

About the Author

Jeffrey Liker

President

Dr. Jeffrey K. Liker is Professor of Industrial and Operations Engineering at the University of Michigan and a professional speaker and advisor through his company Liker Lean Advisors (LLI), an organization established with a network of associates to teach and consult in the Toyota Way. He is also CEO of Lean Leadership Institute, the home for online courses beginning with The Toyota Way to Lean Leadership.

Dr. Liker is author of the international best-seller, The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer (McGraw Hill, 2004), which speaks to the underlying philosophy and principles that drive Toyota's quality and efficiency-obsessed culture. The companion (with David Meier) Toyota Way Fieldbook (McGraw Hill, 2005) details how companies can learn from the Toyota Way principles. His book with Jim Morgan, The Toyota Product Development System (Productivity Press, 2006), is the first that details the product development side of Toyota. His articles and books have won nine Shingo Prizes for Research Excellence and The Toyota Way also won the 2005 Institute of Industrial Engineers Book of the Year Award and 2007 Sloan Industry Studies Book of the Year. In 2012 he was inducted into the Association of Manufacturing Excellence Hall of Fame. He is a frequent keynote speaker and consultant.