Transformational Change vs. Continuous Improvement

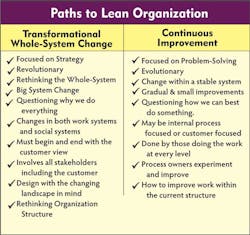

It may sound like sacrilege to hear someone say that continuous improvement may not always be the right answer. Of course, it is the core process of lean management. But, there are times when more significant and more rapid change is required – sometimes revolution rather than evolution is called for.

A couple examples: First, some years ago I was speaking at a Toyota suppliers’ conference and had lunch with a group of Japanese Toyota consultants who worked with their suppliers. The young president of one supplier had these consultants come in and completely re-organize his factory. They sent all the workers home, insisted that the CEO stand aside and not interrupt their work. They ripped all the equipment out of the floor, reorganized the placement of every piece of equipment, changed the flow of work, redefined every job, and when the workers returned they were all oriented to their new work assignments.

This was not continuous improvement by those at the gemba. It was a radical, revolution in the whole-system of the organization.

Second example: Toyota itself, in the 1990s, had a turnover rate of 25% among newly hired workers, and they were running out of workers. They realized that there was something dramatically wrong with their system. Along with their union, they redesigned their own system to the degree that one writer claimed that Toyota had abandoned lean manufacturing altogether. They had not abandoned it, but their previous focus on the technical system alone had created misalignment with the needs of people, and they had to redesign to align the social and technical systems.

Third example: A Canadian health care organization that provides home care had centralized the planning and scheduling of nurses and home support workers. They created a call center in one location to which calls from all over Canada came, and this center scheduled nurses throughout the provinces. It was supposedly going to create savings due to the economies of scale, all scheduling in one location.

The customers hated it! They never knew who they were talking to. The employees at the call center didn’t have personal relationships with the nurses or the funding agencies, and customer intimacy was impossible. They were engaged in continuous improvement within the call center. However, they could have done that for years and never corrected the fundamental problem. It had to be closed down, the scheduling function decentralized to the local districts where the schedulers could have close contact with the nurses and the funding agencies. The whole system was blown up! Now the funders are happy, productivity is improved, and costs have been reduced.

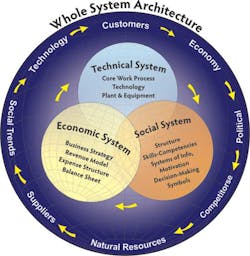

In all three of these cases, continuous improvement could not get you there! The first thing to understand about transformational change is that the external environment -- technology, regulation, competition, the economy -- is forcing change upon your organization. Your organization is a sub-system of a larger system, and it must align its systems to the external world. Sometimes that external environment demands rapid change that may be uncomfortable for everyone.

Second thing to know is that every organization is a “whole-system.” Lean management is a whole-system. It is not 5S, teams, or process maps. It is everything from the organizational structure, the information system, the decision-making processes, the human resource systems, etc.

Most companies that have tried to adopt lean management have disaggregated that whole-system and implemented some pieces of it. They have implemented 5S, just-in-time, work teams or problem-solving groups and have often experienced failure. The human body is a whole-system comprised of separate organs or sub-systems, and they fit together as unified architecture. The heart relies on the lungs for oxygen, and they both rely on the digestive system for nourishment. If you remove any of those sub-systems from the whole, that organ will quickly die.

In the same way, pieces of lean management most often die like organs removed from the body because they depend on the other organs for their survival. You cannot implement a lean management structure, with strong teams at every level, without changing the decision process, the information flow, and the reward systems. You cannot implement just-in-time work flow without changing the information flow, the decision-making process and without redefining jobs at the first level. And, you cannot implement lean culture without changing the functions and structure of management. These are all organs of the same body.

Third thing to know: Sub-systems of the whole must be aligned. My firm had been hired to help implement a team-based organization in a manufacturing plant. We were to design the team system and provide training. But when walking through the plant, the plant manager told me that we didn’t need to worry about the compensation system. He had another consultant working on that. I asked how the employees were paid. They were paid on a piece rate system that the other consultant revised each year. So… we were to get them working as great teams while they were paid on individual piece rate! I told him it would fail. The whole-system must be aligned.

Misalignment Undermines the Best Intentions

If you want great teamwork at any level, the incentives have to be based on teamwork. There are a hundred ways in which misalignment of sub-systems can undermine the best intentions of any change process.

When many companies begin their lean journey, they may not realize that both Honda and Toyota started their operations in the United States and other countries outside of Japan with a greenfield site where they designed the plant layout, organized the equipment, aligned their suppliers, hired all of the managers and associates, and trained them in their way. They created a unified whole-system whose parts were all aligned to the same philosophy. They were not changing a culture, overcoming resistance, or redesigning existing facilities. However, this is entirely different than the challenge facing most companies. Toyota and Honda succeeded because they had a unified, whole-system that they built over time and for which they have common understanding and commitment at every level of the organization. In that sense, they had it easy.

The Problem with Problem-Solving

We have been introduced to many problem-solving models as the solution to all ills. Whether it is Six Sigma’s DMAIC, or the Shewart Cycle of PDCA or PDSA, or the A3 problem-solving model, they are all predicated on the idea that there is a specific problem to be solved. Why do you think there are so many problems? Could it be that there is something more fundamentally wrong?

Problems are within the current state system. They are by definition history. Transformational change is not problem-solving. It is designing the whole-system to meet the needs to customers and the future environment. It is an act of creating something, not fixing something.

Transformational change is about proactively creating the future organization and system. It asks, “Given the future environment, the technology, the market and social changes, what do we need to be like in the future, and how do we create that future?” It is designing a fundamentally different house than the one we are living in. Yes, there is a “problem,” but you won’t find the problem by fixing every rash and headache. The problem is that the design of the organization is not suited to its current or future needs.

Transformational change is a process designed to create significant change in the culture and work processes of an organization and produce significant improvement in performance. If your organization has a relatively traditional culture, you need transformation to engage your people, gain understanding and commitment to change. If you only need to make small improvements, to engage people in continuous improvement, you do not need whole system architecture. The American auto companies desperately needed to make significant change in their culture, but instead of a serious approach to analyzing and changing the culture, they opted for a less threatening and less dramatic approach of small groups working on small improvements. It was too late for that.

If you need to align your organization and culture to your strategy, you need whole-system design. If the organization creates walls and barriers to the flow of work, you need whole-system design. If the market place is changing significantly and your organization needs to respond to changing technologies, customer demands, or regulation, you need whole-system design. And, if you have had difficulty implementing change, gaining commitment from your own managers and employees, you need whole-system design.

Lawrence M. Miller has been doing organizational change consulting for 35 years, beginning with his work creating a free economy in prisons. He has worked with Honda, Shell Oil, and dozens of other corporations. He is the author of 10 books, most recently Getting to Lean – Transformational Change Management. His website and blog is www.ManagementMeditations.com. He can be reached at [email protected].