A Smarter Approach to Procurement

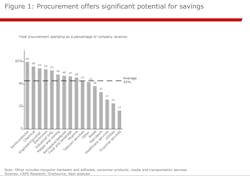

Most companies only scratch the surface of procurement efficiency. Those that dig deeper discover that the savings can be dramatic. External purchasing is the largest single expense category for most firms, averaging 43% of total costs. Bain research shows that world-class procurement organizations can reduce a company’s purchasing cost base by an average of 8%-12% and deliver additional annual savings of 2%–3% (see Figure 1).

A talented procurement team can provide leadership teams with valuable data, analysis and insights that influence what a company buys and how it buys. But many organizations wall off procurement from the rest of the business, treating it as a non-strategic service. Procurement managers that have a mandate to think strategically about what a company buys and spends can make the business case for change. But overcoming organizational silos takes time, and procurement needs to earn a seat at the table with business unit leaders.

Successful companies achieve greater savings by creating a collaborative partnership between procurement and the business, and making both accountable for results. Collaboration enables smarter, proactive purchasing decisions. One example: Procurement can provide regular feedback to business unit heads on where their spending is less efficient than the competition’s. That’s powerful intelligence.

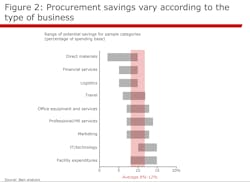

Collaboration is also vital to making sure procurement savings really stick. Often, they evaporate before finance can book the gain. Why? Procurement managers seek to cut category costs (such as travel and entertainment expenses) that typically span multiple budgets, so the savings are difficult for finance to track. As a result, procurement claims large savings that never show up in the company financials—a major point of frustration for CFOs and business unit managers. When procurement and finance work together, they can create systems that reliably capture these gains, delivering real cash savings to management (see Figure 2).

Another important step is building the capabilities to lock in long-term savings. Even when companies achieve significant purchasing savings, many cannot sustain the process. Giving procurement a strategic mandate requires behavior change across the entire organization. Successful companies understand that and invest in the talent and tools to find new opportunities year after year.

Buying and Spending Better

When companies set out to trim procurement costs, they typically focus on the two areas of savings that procurement offices control directly: price negotiation and supplier selection, which both help companies buy better. Negotiating lower prices for everything a company buys may sound obvious, but many companies struggle with how to do this when the offering is more customized, as in certain service categories.

For instance, a global chemicals company achieved breakthrough service savings by benchmarking the labor rates and markups it was paying suppliers against industry standards. That allowed the procurement team to renegotiate labor service contracts, yielding $75 million in savings.

Streamlining suppliers is just as important. When the same company launched a procurement transformation in 2013, one of the first moves was a strategic sourcing process that consolidated 2,000 suppliers worldwide for maintenance and repair equipment down to one main supplier. By doing so, the company won a 20% price reduction, netted more than $10 million in annual savings and improved management efficiency.

Buying better is critical, but spending better can double a company’s procurement gains or more. Bain research shows that techniques for spending better—which focus on what companies are buying, not just what they pay for it—can produce 60% of total savings. Companies that do both—buy better and spend better—canvass the entire landscape of opportunities.

Three guidelines can help companies spend better:

Get a grip on demand. Leading companies streamline purchasing. By examining specific categories, procurement teams can put a spotlight on unnecessary spending.

Design to cost. World-class purchasing teams also make sure design teams are not over-engineering new products. They embed procurement managers in the R&D team to assess the cost of different components and consider alternative options that may be more cost-effective.

Reduce system costs. Successful companies evaluate the total cost of owning expensive items. Paying more upfront can be the more economical choice if savings over time outweigh an initial higher cost. They examine their supply chain to understand whether it makes more sense to produce items in-house or buy them from someone else. And they work with suppliers to reduce supplier complexity and bring costs down.

Closing the Loop to Lock in Savings

All too often, companies reap big procurement savings on paper, but they leak out of the system. It’s an annual ritual many companies know well: The head of procurement touts an impressive savings figure for the year, but a frustrated CFO never sees any real savings in the financial statements.

The reason is clear. Procurement generates savings at the category level, but business-unit managers spend at the budget level. Since most companies don’t have transparent systems that map categories to budgets, managers often take savings from one category and spend them elsewhere. Of course, when managers spend their entire budget, procurement savings quietly disappear. By that time, procurement teams already have reported the gains to finance and moved on to the next initiative.

Leading companies close the loop by connecting procurement and finance to make sure category-level savings flow into the current year’s budget. When Boston Scientific revamped its indirect procurement in 2015, the executive team was determined to capture the savings in real time—and to consciously decide whether to reinvest in growth or let the gains flow to the bottom line. That meant breaking down outmoded barriers between procurement and finance and helping finance see where the procurement savings were being generated budget-by-budget.

The company used cross-functional teams and category-sourcing plans to translate category-level procurement savings into specific budget-level targets. They then put systems in place for the finance department to track and channel those category-level savings into specific budgets. As a result, Boston Scientific expects to deliver $30 million in savings tied to specific budgets, allowing the leadership team to make clear choices about how to spend the windfall.

By helping management generate and actually capture the savings, procurement managers at Boston Scientific earned trust and influence across the entire business. Closing the loop created a virtuous circle.

Making the Savings Stick

Even when companies identify big procurement gains, the discipline typically is short-lived because they haven’t built the organizational capabilities to sustain annual procurement gains of 2%-3% over time. It’s hard to do because building cross-functional coordination and collaboration involves behavior change across the entire business.

Investing in the procurement team’s capabilities is also critical, particularly following major acquisitions. In 2011, Lenovo realized after a series of acquisitions that its six procurement centers around the world had widely divergent skills and practices. In response, it launched a global training program for 300 people with a focus on category management, including strategy development and stakeholder engagement in addition to the core procurement skills of negotiating and sourcing. That helped procurement teams collaborate effectively across all business units and with suppliers.

The result was a steady stream of cross-functional initiatives—where there had been none—that continue to deliver gains. In one of the company’s highest-cost categories—original design manufacturing for the T Series ThinkPad—procurement orchestrated a different type of working relationship between the supplier and engineering. By negotiating with more transparent cost data, it shared more risk and promoted long-term partnership, generating $90 million in savings.

Ultimately, a more strategic role for procurement helps companies invest in and attract talented people whose capabilities are critical to sustaining behavior change. The right procurement talent also can set up strategic relationships with suppliers that underpin innovation and create competitive advantage.

A skilled procurement team with a strategic mandate can unearth hidden savings and deliver additional gains year after year. By bringing procurement into the routine process of decision-making, the entire leadership team is more attuned to opportunities to liberate cash that can be invested in growth. That, in turn, helps companies put the right organization in place to deliver savings that stick.

David Schannon is a partner in the Silicon Valley office of Bain & Company, a management consulting firm. Sam Thakarar is a partner in Bain’s Boston office. Klaus Neuhaus is a partner in the company’s Düsseldorf office.