As the leadership team at a consumer products company debated its digital strategy, two opposing views emerged. To stay competitive, some argued, the company needed to invest several hundred million dollars to automate its existing network of large regional plants. Others insisted it should hold off given how rapidly digital was changing the business. What if automation, mass customization and increasing customer expectations require a future network of much smaller plants closer to the customer and capable of same-day delivery?

The leadership team was prepared to make a large investment, but it feared betting on the wrong trend. Yet if it waited, it risked falling further behind its competitors.

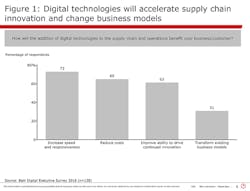

This catch-22 is playing out in the boardrooms of many companies as executives map out digital operations strategies. Many understand that to be competitive five to 10 years from now, they need to start building their digital capabilities today. They also know that investing in digital operations is no longer just about improving efficiency. Big Data, advanced analytics and connected hardware are powerful tools that can change a company’s strategic direction and create new sources of competitive advantage (see Figure 1).

Often, companies hesitate to invest because the fast-moving digital universe is difficult to reconcile with the long lead times required to build out new assets in operations. On top of that, operations tends to be large and mission critical, so leadership teams have little room for error. As a result, operations, with its traditional long-term approach to planning, is particularly vulnerable to digital disruption.

Take the example of the retail industry, in which Amazon leveraged its digital operations to pioneer 48-hour, 24-hour and then same-day delivery. Amazon began shrinking its delivery times more than a decade ago, so retailers had plenty of time to recognize what was happening and react. However, few of Amazon’s competitors invested in these capabilities, and as a result, most found themselves far behind the development curve when Amazon’s rapid delivery times became the norm.

Successful companies recognize that while it’s impossible to predict the future, delaying an investment in digital operations can make them vulnerable. For some, it may even doom the business. But how can companies choose a direction amid all the digital noise? Digital leaders identify two or three trends that are both highly likely and dangerous to ignore, and they make sure they have strategies to address them. That approach allows them to cut through the noise and concentrate on what really matters.

Digital leaders also understand that they may have to take a first step without fully knowing what their second step should be. In operations, failing fast—the trial-and-error tenet of digital strategy—often is not an option. Operations executives are accustomed to detailed, long-term planning, so many may be uncomfortable with an agile approach. But it can help them navigate in uncertainty. By contrast, developing the perfect long-term operations plan or waiting to see how trends unfold carry big risks.

The Amazon example highlights a practical way forward. Even when leadership teams don’t know where digital trends will lead, they can identify those that pose major risks or represent big opportunities, and start responding step by step. For rival retailers, it was clear Amazon was shortening its delivery times and that at some point, its service might even transform customers’ expectations.

Dreamers vs. Doers

Organizations are composed of two types of people when it comes to digital—the dreamers and the doers—and it’s important to include both when shaping a future vision for operations. The doers tend to concentrate on the here and now. They want to cut through the digital hype and implement practical digital initiatives that create value today. The dreamers, by contrast, are more focused on the long term. They envision a bold future in which digital technologies completely transform their industry or business.

Both perspectives are valid, and the best digital strategies reconcile the views of the doers and the dreamers. Too much focus on the doers can lead to a lack of long-term strategic direction. While any one investment in digital might make sense, doers can fail to fully grasp the more transformative opportunities and risks posed by digital. That can put a company at serious risk of disruption. On the other hand, overreliance on dreamers can put a company’s existing operations at risk if they bet too heavily on an uncertain future. The trick is finding the right balance between the dreamers and the doers—and in operations, that’s a huge challenge.

Why? It’s mainly the doers who set the operational agenda, and for good reason. The traditional priorities within operations have been continuous improvement, continuity of supply and operational stability. Historically, operations executives have been satisfied with efficiency gains of 1% to 2% per year.

But the dominance of doers leaves operations more vulnerable to digital disruption than perhaps any other function. And given the significant time required to build capabilities and hard assets, operations can suddenly find itself years behind the competition. Digital leaders make a deliberate effort to incorporate dreamers’ views—they even go outside operations to invite dreamers from the broader business into the digital operations discussion.

How to Get There

Digital technologies have introduced uncertainty into every business, but operations executives have a particularly challenging task identifying the best way forward. Leading companies start by taking small steps toward building the capabilities that will be required to win in the future. Five guidelines can help companies get started:

1. Give operations executives a bigger role in setting strategy. In a digital world, operations executives are increasingly responsible for helping develop the company’s strategy, not just implementing it. Digital has unlocked a new set of capabilities that companies can use to out-maneuver the competition.

2. Take the first steps. Identify a few digital trends that matter most to operations, and determine a strategy that positions the company to win. Use the company’s digital vision as a guide to ask the question: Does this investment or decision move us toward that vision? That doesn’t mean all companies have to make a significant investment in digital operations immediately. In some cases, the technology may not be available yet. Leaders make staged investments that move them in the right direction.

GE, for example, decided 3-D printing was likely to have a disruptive impact on its businesses in the future and invested $39 million in 2016 in its Center for Additive Technology Advancement in Pittsburgh. Few of GE’s individual business units would likely have invested in the technology since it was not important to their current business models. But GE recognized that 3-D printing would be critical to win in the future, so it required all of its business units to co-fund the center, significantly lowering the threshold for any given business unit to test and deploy the technology.

3. Set ambitious targets. In addition to continuous 1% to 2% efficiency gains per year, aim for much larger gains on the order of 10% to 15% (or more) in three years. This kind of performance leap requires a new mindset within operations. The CEO of a global industrial machinery manufacturer that had already been through several lean programs set a much more ambitious target of 30% improvement in operational efficiency by 2020. The only way to achieve that ambitious leap was to invest heavily in digital technologies. The company has started improving the flow of information from sales to production and installation, reducing delays and costly rework. It also has increased field service efficiency by using analytics to predict component failures and replace those components during routine visits.

4. Invest in capabilities.One of the biggest challenges is finding top digital talent for operations. Digital leaders start early, investing in the skills and expertise. They look for opportunities to build competence in areas such as automation, predictive maintenance and the Internet of Things (IoT). That’s a critical first step since different digital interfaces and systems often don’t work together. Selecting vendors also becomes more complex due to new digital platforms for IoT and the required interoperability with existing platforms.

One global manufacturer created an internal innovation group to increase its expertise in analytics and IoT and to spread best practices throughout the company. That allowed each business unit to leverage the investments that other areas of the business had made. The group became so knowledgeable that it eventually began selling its expertise to the market as a service.

Companies that are not ready to invest heavily in internal digital capabilities can still move toward a more digital future by using software as a service, the cloud and more outsourced logistics. On the other hand, companies with the financial capacity to sustain more risk may bet on becoming a first mover. For instance, one global transportation company is investing more than $400 million in a prototype greenfield factory of the future to test IoT technology and accelerate its learning. Not only is the site a potential template for future greenfield plants, it will help management understand where the return on investment is highest for using new digital solutions in existing factories.

5. Add Non-operations Members to the Team. Cross-functional teams that include both doers and dreamers are best able to design an investment strategy for digital operations. Their different perspectives are vital to understanding where the business is going, how customer needs are changing, how competitors are likely to evolve and new business models that may emerge.

Digital technologies are likely to create new winners and losers at a pace industries have not experienced in the past. They also may prompt significant changes to the organization or operating model. Companies that identify the digital trends affecting their industry and customers now and that begin experimenting will be best placed to navigate the changes ahead.

Nate Anderson is a partner with global management consulting firm Bain & Company in the Chicago office.

About the Author

Nate Anderson

partner

Nate Anderson is a partner with global management consulting firm Bain & Company in the Chicago office.