7 Signs That Now Is the Time for Energy Harvesting

Energy harvesting collects energy that would otherwise go to waste, such as heat, vibrations, and sunlight, then converts it to electricity and puts it to use. It may not be a technology you are familiar with, but it is poised to become mainstream and change the way we power our electronic devices and what we think of as an energy source.In many cases, energy harvesting can eliminate batteries from wireless devices.

In other cases, it lets batteries be augmented by other power sources, improving reliability and extending the operational life of the device. Several key concepts are coming together to make energy harvesting an even more popular choice for powering devices.

Let's look more closely at seven forces that are driving the technology today.

Transducers Are Getting More Advanced

Available energy sources are all around us, from both man-made and natural sources.

The goal of energy harvesting is to capture the currently unused energy and convert it to electricity. Transducers are the devices that turn one form of energy into another. A human’s sense organs, for example, are transducers that turn light, chemicals, pressure, and motions into nervous signals. Man-made transducers, also called sensors, do the same thing, but often convert the input (color, sound, chemical presence) into an electrical signal.

Steady advances in transducer technology, especially recent breakthroughs in materials and semiconductors, have made new types available and increased the efficiency of all of them. Micromechanical systems (MEMS)—moving parts built onto application-specific ICs (ASICs)—are a good example. They let complete transducers be built on a single chip, thus opening the door to major improvements in efficiency and cost. Other on-chip transducers are now available for temperature, chemical detection, and pressure. Surface acoustic wave (SAW) resonators are another good example. SAWs have been understood for over a century and the resonators have often been used in filters and oscillators. Today, new techniques are creating transducers useful for converting sources of mechanical and acoustic energy into electricity.

As transducer types and efficiencies expand, so do the methods and tools of energy harvesting.

C Chip for Energy Harvesting and the IIoT

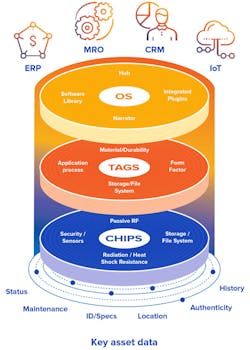

Tego’s Asset Intelligence Platform uses energy harvesting for IIoT applications. Data connectivity is handled by rugged industrial products/assets or components beginning at the time of manufacturing so that the product can tell a story about its manufacturing processes, materials, and entire lifecycle of activities. Information stored on the product or asset itself streamlines processes and everyday activities for distributors and aftermarket service providers. Data on the asset transforms how all stakeholders see, act, and engage with the asset.

The platform has three layers, the foundational layer being the TegoChip which is a UHF RF chip that harvests energy from readers to read, write, and manage structured and unstructured data, files, and images stored on the asset or product. TegoChips are packaged inside TegoTags, which can be embedded into materials of finished goods, can survive rugged manufacturing processes including gamma sterilization, and tags can be optimized depending on how they are used and the amount of data stored on the asset. Products with the chip are “born” smart and they gather information and data, history, and condition changes throughout its lifecycle.

The information gathered, stored, and managed on the product is critical to asset lifecycle management, regulatory and safety compliance, and/or integrity management.

TegoOS is the communication layer of the AIP that lets qualified stakeholders with an iPhone, Android, or Windows operating system read, write, manage, and store data on any product or asset.

Low-Power Circuitry Uses Even Less Power

Just as the power available from transducers has been increasing, the power needed to run electronic circuits has been decreasing. That’s because at a given switching frequency, power requirements fall as a device’s geometries shrink. A good example of this is the RFID chip. Current versions have enough processing power to perform a digital handshake with the reader and respond to dozens of commands, yet they only need 10 microwatts to operate, meaning they can operate by converting the RF energy from the reader into electricity, so they do not need batteries.

Power improvements do not totally depend on semiconductor advances. Power consumption has become a major concern with larger chips such as microprocessors, graphics engines, and communications devices. But their appetite for electricity has motivated circuit designers to develop low-power designs for digital and analog circuits. The improvements made for large chips are being carried over to smaller circuits, resulting in devices that can be powered entirely from harvested energy.

The IoT Is Driving Devices Closer to the Edge

The Internet of Things (IoT) is here and expanding rapidly. Depending on which analyst you refer to, predictions of connected “things” range from 20 billion to 50 billion in three years. Our computers, smartphones, and web servers are already connected, so the next connectivity wave will focus on devices. Most of those devices will not be continuously powered, always on, and with their own IP address. Instead, they will mostly be small wireless devices that push the edge of the network farther and farther from the nearest data center.

We are rapidly approaching the point where the internet’s endpoints are data collections associated with a single item rather than powerful computers all talking to each other. These items might be automobile components moving through an assembly plant, packages of drugs or food traveling through a supply chain, or tens of thousands of tiny sensors scattered across a farm. Every case is an example of the move to highly distributed data and an understanding of the value these smart assets have in revealing operational data regarding quality, maintenance, and opportunities.

As connected devices get smaller and further out on the edge, powering them with batteries becomes more of a problem. There are industries such as aviation and energy where assets are expected to last for decades and the number of parts in service and inventory can number in the hundreds of millions. The prospect of replacing batteries, even as infrequently as every five to 10 years, is simply a non-starter. In other cases, the network edge is so “out there” that accessibility is a major hindrance. Consider sensors embedded within structural members or walls. Battery replacement is simply not an option in such locations.