As manufacturers consider candidates to add to their talent pool, what do you think indicates a better predictor of success: credentials or experience? While the U.S. manufacturing skills gap seems to widen each year, hiring managers may soon realize that employees with the right credentials may be just what the sector needs to fuel the next talent boom—and the economy.

A recent Workcred report sheds light on the potential of credential use in U.S. manufacturing. But it also delves deeper to reveal just how credentialing can improve what matters most: helping employers keep pace with the demand for new and changing workforce skills.

As the executive director of Workcred, an affiliate of the American National Standards Institute (ANSI), I am dedicated to the mission of strengthening workforce quality by improving the credentialing system, ensuring its ongoing relevance, and preparing employers, workers, educators, and governments to use it effectively.

We know this: Consumer demand will fuel the next wave of technological innovation, with a projected 3.5 million new manufacturing jobs over the next decade. Alongside this rapid increase in output and productivity is the daunting prediction of a skills mismatch leading to a workforce shortage and as many as 2 million job vacancies within the sector. Credentials are one solution to the challenges of upskilling workers and evaluating relevant attributes of potential workers.

Workcred's newest report, entitled Examining the Quality, Market Value, and Effectiveness of Manufacturing Credentials in the United States, provides insights on how manufacturers use and determine the value of credentials to meet their talent needs.

The study was funded by the National Institute of Standards and Technology (NIST) Hollings Manufacturing Extension Partnership (MEP) and is freely available for download. The findings detail recommendations for manufacturers, credentialing organizations, education and training providers, accreditors, and policy makers.

Bring Transparency to Credentialing

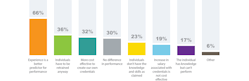

The study revealed that many manufacturers do not know what credentials are available or how they are relevant. Confusion over an expanding credentialing system points to a major challenge: employers who do not know what credentials are available cannot recognize the unlocked potential that credentials may have, especially in the face of the growing skills gap. The findings also suggest that credentials are not routinely required or used as a major factor in hiring or promotion decisions: while 45% of manufacturers responding to the survey said they prefer credentials, 30% reported not using them at all. The top two reasons that manufacturers said they did not use credentials were because they felt credentials were not relevant to the jobs in their facility and that credentials did not make a difference in an individual’s performance. For those who selected the latter, 66% felt that experience is a better predictor of performance, and 36% said they needed to retrain credential holders anyway.

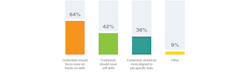

Yet on the flipside, the report confirmed manufacturers believe that credentials could serve as a critical resource if they focused more on hands-on skills, addressed soft skills, and were better aligned to job-specific skills.

How to Use Credentials to Meet Organizational Needs

To help strengthen the quality, value, and effectiveness of manufacturing credentials in the U.S., the report features recommendations for manufacturers, credentialing organizations, education and training providers, accreditors, and policymakers. Recommendations specific to manufacturers address the need to:

- Support efforts to increase transparency about the purpose, use, and competencies of credentials

- Promote competency-based apprenticeships

- Align competencies and create a continuous feedback process

- Increase opportunities to demonstrate workplace behaviors

- Increase opportunities to earn credentials that also assess employability skills in secondary schools

- Increase engagement of manufacturers in the development of credentials

- Develop credentials for growing and evolving roles

Increased productivity and output are good news predictions for the manufacturing sector. The skill shortage can be alleviated with better understanding and use of credentials to assure that we can offer a skilled workforce to fill the demand and to upskill our existing workers, too. Workcred is already working with NIST MEP and manufacturers to identify where additional research may be needed to improve understanding of the effectiveness and return on investment of credentials in this important sector.

Roy Swift, Ph.D., is the executive director of Workcred and served as the chief workforce development officer at the American National Standards Institute (ANSI). Workcred, a nonprofit formed in 2014, has a mission of strengthening workforce quality by improving the credentialing system, ensuring its ongoing relevance, and preparing employers, workers, educators, and governments to use it effectively. Its vision is a labor market that relies on the relevance, quality, and value of workforce credentials for opportunities, growth, and development.