Here's a prediction: Part forming via casting and machining will increasingly face competition with e-manufacturing, a material additive process using laser sintering. The supporting evidence comes from a survey of experts at the K 2007 show in Dsseldorf and Euromold 2007 in Frankfurt. The data was collected by Germany's EOS GMBH, Munich, a specialist in building parts via laser sintering of selectively deposited metals and plastics.

Respondents were asked to focus on the following core questions:

- What will the production of tomorrow look like?

- Is individual series production from CAD data going to prevail in the future?

- Which technologies will drive this type of production?

Responses suggest that industrial production is confronting a paradigm shift, says Hans J. Langer, EOS founder and CEO. (His U.S. operations are based in Novi, Mich.) He says the experts foresee a trend toward e-manufacturing with laser sintering confronting today's conventional technologies such as casting or machining.

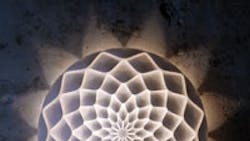

In e-manufacturing end products, functional parts and tools are delivered directly from CAD data. A laser heats and melts powdered plastics or metals layer by layer until the build is complete and a final part or product can be taken out of the system. Langer says e-manufacturing enables the creation of products with highly complex and filigree structures and forms that would be impossible for conventional series production. The scope of possibilities includes jewelry, clothing, lamps and chairs as well as functional parts for conventional production processes.

Langer says 70% of the respondents believe the concept is ready for the mass market, adding that 33% believe that individualized production with laser sintering is already market-ready, while 37% predict the establishment of the technology in the market within the next three years. He says the rest anticipate establishment of e-manufacturing within five years, with only 4% seeing a lag of 10 years.

- 28% say the trend toward individualized series production is the most important factor for the success of the technology.

- Nearly a quarter of the interviewees see greater cost savings compared to conventional technologies."

- 22% believe that e-manufacturing will overtake traditional technologies due to "short product lifecycles."

- Significantly fewer interviewees count factors such as "automated, unmanned production" (15%) and "decentralized production" (11%) as primary success factors.

As with every innovative technology, e-manufacturing with laser sintering is not completely immune to competition from other methods. Conventional technologies still offer some advantages, according to survey participants:

- 29% say the limited choice of materials is the greatest barrier to implementation of e-manufacturing technology. (Langer says material development is receiving special emphasis.)

- Approximately a quarter of the respondents judge the "lack" of know-how in the industry as a hindrance.

- Another quarter think that lack of awareness about the technology is the main obstacle.

- The rest cite "lack of innovative power across companies" (12%) and "outdated production structures" (11%).

Langer says the majority of the respondents feel that the difficulty is not so much the emerging technology itself, but rather a lack of knowledge and openness in the industry.

Finally the respondents were asked for their predictions about production methods 20 years in the future:

- A clear majority (63%) forecast the establishment of individualized mass production in the Western world.

- 21% believe that end customers will have their own mini-factories and produce their own products with rapid manufacturing techniques.

- About 9% of those asked went so far as to remark that, in 20 years time, manual manufacturing will only take place on the PC.

See Also