Manufacturers have been outsourcing their production overseas (a process known as offshoring) for years, and not just because of the low direct labor costs. As sourcing consultant Mark Hehl, president of Hehl & Associates, points out, companies also can enjoy lower operational costs due to such factors as lower overhead; fewer front-office personnel; fewer safety, labor and environmental regulations; relocation incentives; lower material and real-estate costs; favorable currency exchange rates; and the opportunity to sell into the local (in-country) market.

"Outsourcing projects usually are remotely managed, involve less developed organizations and involve other diverse cultures," says Hehl. "These factors add complexity and are more challenging to managers than purely domestic projects." In his practice of helping companies make the offshoring transition, he has encountered many of the common challenges and pitfalls facing those responsible for outsourcing project success. He offers the following suggestions based on his familiarity with such low-cost countries and regions as China, India, Southeast Asia and Latin America.

Due Diligence

Begin by performing extensive research so that the most optimum region and the right business partner are found. According to Hehl, many organizations become infatuated by the lowest-price alternative and do not consider total cost, and as a result suffer the negative consequences. He recommends that companies not only due their due diligence, but that they then repeat the process at least three more times to avoid being "beaten before you start."

Manage the Risk

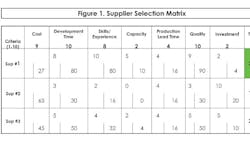

Figure 1 (below) shows an example of an analytical technique that one of Hehl's clients employed to select the overall best business partner for a new product launch. As Hehl points out, "Although price was rated very high, the low-price supplier was not chosen as other important factors were also seriously considered." The customer, he reports, had a very successful product launch and all indications are that this product will be very profitable.Relationship Building

"Business relationship expectations in low-cost regions are different than in North America and Europe, where getting down to business fast is the norm," Hehl observes. "Your Asian and Latin American counterparts expect to spend considerable time getting to know you better before discussing business." He recommends that you begin the process by developing a relationship, preferably in a social setting. Also, learn at least some of the local language and begin conversations in the native tongue.

Benchmarking

When considering a particular region seek out other foreign businesses that have operations there, Hehl suggests. The idea is for you to learn from their previous experiences to get a better sense of what to expect.

Local Managing Director

Hehl recommends the hiring of a local general manager to run the day-to-day operations. "This will help with the retention of key personnel, and the workforce will be more apt to follow a local manager. The motivation levels are higher when a local person is in charge. Hire someone with local government affiliations." Local officials, Hehl adds, are critical to your success overseas, as without their help, most ventures are doomed to fail.

Develop Your Partners

The level of technical and managerial expertise in low-cost countries is usually below that of the more developed world, so a comprehensive training and development program is necessary, Hehl says. "Your business partners must realize from the start that continuous improvement is a business necessity and a part of everyday life."

Look Before You Leap

Once you reach the final stages of selecting a supplier, take the time to conduct a comprehensive evaluation of all your supply-chain partners, Hehl recommends, and don't just limit it to operations, quality and capabilities. He suggests you include other areas such as social accountability, accounting, material control, safety, planning, logistics and supplier management."

See Also

About the Author

Dave Blanchard

Senior Director of Content

Focus: Supply Chain

Call: (941) 208-4370

Follow on Twitter @SupplyChainDave

During his career Dave Blanchard has led the editorial management of many of Endeavor Business Media's best-known brands, including IndustryWeek, EHS Today, Material Handling & Logistics, Logistics Today, Supply Chain Technology News, and Business Finance. He also serves as senior content director of the annual Safety Leadership Conference. With over 30 years of B2B media experience, Dave literally wrote the book on supply chain management, Supply Chain Management Best Practices (John Wiley & Sons, 2010), which has been translated into several languages and is currently in its second edition. He is a frequent speaker and moderator at major trade shows and conferences, and has won numerous awards for writing and editing. He is a voting member of the jury of the Logistics Hall of Fame, and is a graduate of Northern Illinois University.