When fire was first invented, it was a big thing. After a while the fervor died down, and fire became just a daily part of life. The same goes for teaming. When the practice of teaming was introduced, every manufacturer wanted to jump on the bandwagon and circle uncharted territory with the new concept. They shouted far and wide for customers and suppliers to hear: "We have cross-functional work teams that can reinvent how we make the wheel! We will be able to do it cheaper and faster, and we will pass along the savings to you!"

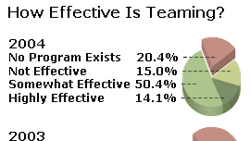

While the practice of using teams to improve efficiency is still alive today, teams don't get a spotlight. They have become embedded in the fabric of doing business. Granted, some manufacturers don't prescribe to teaming, but an increasing number are. According to the IndustryWeek/ Manufacturing Performance Institute's Census of Manufacturers for 2004, 20.4% of respondents stated "no [teaming] program exists" compared with 27.7% in 2003.

Making Teams Effective

Those manufacturers creating teams for the first time will learn that, like fire, the usefulness of teams is all in the application.

Why such a discrepancy?

"Doing teams for teams sake can be counterproductive," says Kevin Gromley, Detroit-based partner and global leader of the Manufacturing Industry Consulting Practice at Deloitte Consulting. "Teaming works when there is a clear business purpose for having the teams. And the team needs to be supported by the right infrastructure in terms of the skills and the training of the individuals -- the right management support, the right tech support. Cases where teams don't work is where they are lacking one of those elements -- either there is not a sound business objective for why the team exists or there is, and the team is lacking one of those elements of capabilities."

Another interesting trend comes from the 2004 IndustryWeek's Best Plants Statistical Profile, which crunches the numbers from the Top 25 Best Plants for 2004 and shows comparisons from past Top 25 winners.

When asked how many production workers are in self-directed or empowered work teams (as a percentage of the workforce), on average 70.2% of respondent's workforces participated in such teams in 2004. Compare this with 85.7% in 2000 and it seems that work teams are going by the wayside. Or are they?

"Teaming as a discipline is alive and well and if anything, it is probably increasing in prevalence and importance," says Gromley. "I think that what you are seeing in your survey is that it is becoming embedded in the organizations and in parts of other initiatives or day-to-day operations."

Gromley sees three trends that relate to this:

- Disciplines around Six Sigma and lean manufacturing are becoming more and more prevalent. At the core of both of those disciplines is cross-functional teaming.

- Product teams are not a new concept, but they are becoming more global in nature and are becoming more prevalent throughout the product lifecycle.

- And the third trend is the notion of global teams. "The current trend I see is creating teams that cross geographic boundaries," adds Gromley.

Teams Go Global

For Steelcase International, a furniture manufacturer based in Strasburg, France, (Steelcase North America is based in Grand Rapids, Mich.), the notion of global teams is instrumental in doing business. The $2.3 billion company employs 14,000 and has a presence on every continent with manufacturing facilities in 20 countries.

According to Florent Buiron, CRM Team Leader International, 30 years ago Steelcase teams were aligned with geographies, meaning U.S. teams for the U.S., France teams for France, etc. There also was an alignment along functional boundaries, where finance folks worked only with other finance folks.

Today, Buiron, who is based in France, says Steelcase teams have evolved into cross-functional, cross-geography, virtual teams.

"We are trying to align our processes across different geographies and trying to share resources and expertise across several geographies. When we moved into virtual teams there were two phases. One was done without thinking about it -- one could say it was out of necessity and out of survival. The second phase, where the organization is now, is a structured effort to have best practices put in place as far as putting virtual teams together, making sure we have the right tools, making sure we have the right training and coaching programs to help people work virtually and still be effective."

For Steelcase, teams are a way of life and survival. Gone are the days where products are developed purely with a national focus. "When we develop new products or marketing programs or IT tools or new processes to make our organization more efficient, those are designed for many geographies at the same time and sometimes for the whole world."

Despite the excitement over teams, there are award-winning manufacturers that don't incorporate teams into the fabric -- a case in point is Delphi Corp.'s Cortland Precision Molding Plant in Cortland, Ohio. A 2003 winner of IndustryWeek's Best Plants award, the plant at the time recorded that only 5% of its workforce worked on empowered work teams.

In Patricia Panchak's Best Plants profile of Delphi ("Running Like A Charm," October 2003), the plant manager notes that the practice doesn't follow the unwritten rules of manufacturing: "It's unconventional in some ways," admits [Plant Manager John] Stefanko. "But if you study and understand the business, it makes sense."

Like everything else, there is a time and a place for teaming. After all, there is a reason that only 14.1% of companies deem teaming as highly effective.

Teaming In The Future

| Production workers in | |

| Year | Average |

| 2000 | 85.7 |

| 2001 | 77.3 |

| 2002 | 84.6 |

| 2003 | 81.7 |

| 2004 | 70.2 |

| Average number of employees per work team | |

| Year | Average |

| 2001 | 10.5 |

| 2002 | 12.2 |

| 2003 | 12.7 |

| 2004 | 10.5 |

Buiron also observes that the walls of companies are becoming more permeable, and the notion of companies working unto themselves is behind us. "I think the trend is moving to more openness of any organization toward the outside world. Being able to find skill sets and hire skill sets wherever they fit geographically."

As for Gromley's take on the future: "Teaming is an important topic and one that will never go away. It will constantly evolve and be something that leading companies need to be thinking about. It will distinguish the winners from the losers on the global competitive dynamic."