South Carolina – Home Grown Life Science Innovation

It’s not often that a city, in this case Greenville, S.C., can claim that an entire industry was invented there.

Yet that’s exactly what happened in 2003 when former Clemson University bioengineering professor Thomas Boland filed a patent titled “ink-jet printing of viable cells.” This discovery turned into the field known as bioprinting.

Bioprinting, as defined by the is The National Center for Biotechnology Information, a part of the National Institutes of Health, is the use of computer-aided transfer processes for patterning and assembling living and non-living materials with a prescribed 2-D or 3-D organization in order to produce bio-engineered structures serving in regenerative medicine, pharmacokinetic and basic cell biology studies.

How this printing found its way to production at Izumi International is yet another twist in the city’s path of interwoven innovation. Izumi International was founded by Ichiro Izumi in Greenville in 1976 in order to import and export textile machinery. Five years ago some of the company’s engineers began exploring bioprinting. Also at that time the Medical University of South Carolina (MUSC) had been awarded $20 million by the National Science Foundation to conduct biofabrication research. The university wanted to bioprint a “vascular tree”, which is a network of blood vessels.

A MUSC researcher, while at a tradeshow, saw a robot at an Izumi display that he thought could provide the technology necessary for the research they were conducting. The chance meeting resulted in Izumi building a bioprinter for MUSC.

Fast forward to two years ago, Izumi revised its original machine and created the Palmetto Printer. “This printer became the base model for us in this field,” explains Katie Golson, biomedical automation application engineer at Izumi. “Since the field is so new at this point all of our work is customized depending on the research needed. We are working toward a turnkey model that we can take to market.”

With an eye toward commercial production, in November of 2014 Izumi partnered with Xanofi, a manufacturer of nanofibers, to print 3-D polymer nanofibers. Xanofi had developed a way to make nanofibers with properties that have the correct chemistry properties, and Izumi can 3-D print small, discrete, nanofibers. The importance of this partnership is that the nanofibers, when used in cellular research, allow the cells to live in a 3-D environment that more closely mimics the physiological environment.

Importance of the Right Environment

While the right environment is essential for the advancement of Izumi’s technology, the right business environment is essential for growth. “I work with the Upstate SC Alliance on their bioscience taskforce," said Golson. "I feel that in the past five years the region is getting a lot more attention for our life sciences sector.”

In fact the Upstate SC Alliance which represents the northwestern corner of South Carolina, points out that its biopharmaceutical cluster ranks 30th nationwide, with a subcluster ranking of 24th for biopharmaceutical products.

Translating this to companies, there are more than 572 companies and institutions employing 13,520 people in the life sciences industry.

Innovation is a large driver behind the growth of the industry in this area. In fact inventors in the State earned 357 life science patents over the last six years.

Part of the innovation package is the overall ecosystem available to newly created companies.

“We have had nothing but solid encouragement from the Greenville investment community and the accompanying ecosystem,” explains CreatiVasc CEO Steve Johnson.

Johnson was approached in 2007 by Greenville-based surgeon David Cull to bring to market vascular devices used for dialysis. He brought together over 450 potential investors from the area and ended up raising $3.5 million.

Dr. Cull, who had a unique perspective on devising systems, also had the good business sense to involve the FDA in the early stages of development. When in 2012 the FDA, trying to find solutions to the $50 billion cost of chronic kidney disease, put out a call for new technology, CreatiVasc was one of three companies selected. The company’s Hemoaccess Valve System received FDA approval for clinical trials which are now underway. The device allows blood flow in a dialysis graft to be selectively turned on and off which would reduce the need for certain surgeries.

The product, which was presented at the Southeastern Medical Device Association, attracted the attention of John Feltman, a medical device entrepreneur, who invested $5 million in CreatiVasc through a holding company called Brookhaven Medical Inc.

Feltman told greenvilleonline that he feels the system will “become the standard of care for dialysis grafts, and if that happens we’re talking about something that’s going to be a billion dollar product.”

Brookhaven also owns FutureMax Interventional, based in Texas, which manufactures PTA catheters and related devices. Since the technology of FutureMax was a good fit with CreatiVasc, Feltman moved the manufacturing of its devices to South Carolina. Currently a vote is scheduled to merge the companies, with manufacturing based out of Greenville.

The issue of being one company, albeit a small one, is exactly what CreatiVasc had in mind. Unlike many device companies that end up being purchased by large companies, CreatiVasc wanted to remain small and in Greenville. Johnson had been a founding member of the SCBIO, an advocacy group for the life science sector in South Carolina, in 2007 when there was no life sciences ecosystem in South Carolina. “We can do today what we couldn’t do seven years ago,” said Johnson.

Johnson said that part of the success of the many life science companies at various stages in the state is due to early stage funding provided by SC Launch, which provides funding for entrepreneurs and infrastructure to support over 300 high-tech, early-stage enterprises.

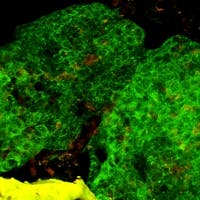

One company that got its start from the fund is Kiyatec. The company uses a process which places the patient’s own living cancer cells into a biologically relevant 3-D culture to assist oncologists with improved response data and faster turnaround.

The company has its connection to Clemson University through the co-founders Matt Gevaert and David Orr, who both have doctorates in bioengineering from Clemson. “We decided to start the company here since there was such a strong ecosystem already in place,” says Gevaert, CEO. “There were five subcontracts in the area that we could use all within 60 miles of Greenville, so we could drive our entire supply chain within one day."

The potential of the company’s process has been recognized and in September of 2014 was awarded a $1.975 million, Small Business Innovation Research Phase II Contract from the National Cancer Institute (NCI).

This grant will allow the company to expand its 3-D breast cancer model to address two issues at the forefront of cancer therapy strategies: 1) cancer's interaction with the patient's immune system (immuno-oncology) and 2) cancer's interaction with the patient's blood supply (angiogenesis).

"This contract is exciting because it recognizes the great potential of our technology, team and strategy to have significant impact on drug development and clinical care," said Gevaert when announcing the award. “The immediate impact will be to use our 3-D breast and GBM models to identify the most active therapies prior to being tested in patients, but our ultimate goal is to use our 3-D micro-tumors as a diagnostic in a clinical trial setting or for real-time clinical decision-making by oncologists."

The NCI contract will further the company’s s mission to arm doctors with drug response profiling (DRP) information that indicates how a patient will actually respond to cancer drugs by growing and treating their live cancer cells in a laboratory. This will allow the doctor to choose the best drug for that particular patient based on prediction of their response, before the patient starts therapy. The approach also translates to late stage "pre-clinical" drug screening, wherein pharmaceutical and biotechnology companies are deciding which drug among a short list of final candidates to advance into a clinical trial for use with patients.

Kiyatec’s success, along with CreatiVasc and Izumi International all relies on the talent and innovation that has been building up in this region for the past few years. All of these companies expect this trend to continue. Perhaps Johnson says it best. “We have no trouble attracting talent to Greenville, it’s a hotspot.”