Having read the title of this article, you may be wondering how it is possible that the eight-hour shift is no longer alive and well, considering it is the shift length your employees currently work. While it may not be gone yet, the eight-hour shift is definitely on the decline.

As North American manufacturers struggle to keep a population of shift workers instead of offshoring the work, management teams must be more aggressive in finding the most profitable work solutions. Those solutions must be balanced with palatable options for an increasingly demanding workforce. It's time to retire the eight-hour shift and consider other possibilities for work that can reduce costs and help companies hire and retain the best talent.

See Also: Manufacturing Workforce Management Best Practices

The manufacturing industry has dramatically advanced in areas of inventory control, workforce management technology and supply chain strategy. However, we're still using the same labor strategies from the early days of the Industrial Revolution, therefore limiting the success of all other advances.

Changing schedules can be disruptive, so it is understandable that many companies shy away from such a task. However, to remain competitive on the operations side and to keep employees happy with new work options that support a better work/life balance, it's time to question whether these eight-hour shifts still make sense.

As we look at alternatives to eight-hour shift schedules, there are many possible options, and there is no single right answer. Every facility has its own operational requirements, employee preferences and health/safety needs. A move to 12-hour shifts could be one way to demonstrate some of the potential advantages of defining new work options.

The right answer for your operation is likely somewhere in the middle, and all potential options should be explored to find the shift plan just right for your company and your staff.

Although the number of people required to cover a 24/7 operation is the same whether a company is working eight- or 12-hour shifts, the actual labor costs are different.

The staffing ratio is 4.2:1 in most cases, meaning that if employees work 40 hours each, it will take 4.2 people to cover each key position over the course of the 168 hours in a week (4.2 x 40 = 168). However, other costs begin to separate eight-hour shifts from others.

There are several factors that play a role in the death of eight-hour shifts. Some factors are strictly business issues related to increased labor costs. These include:

• Shift-change inefficiency and downtime

• Lack of schedule flexibility

• Poor management practices (weekend warrior)

Other factors relate more closely to employee preferences and are equally, if not more, important:

• Turnover/low employee morale

• High absenteeism

• Increased cost to the employee

Shift-Change Inefficiency and Downtime

One large challenge of traditional schedules is shift change. On eight-hour shifts there are three shift changes each day compared to only two with 12-hour shifts. Shift changes create a variety of problems. The first is, invariably, not every employee shows up on time (some not at all) and management is forced to fill positions and shuffle the workforce to get the coverage they need. Simply put, eight-hour shifts cause 50% more shift change chaos than 12-hour shifts.

Downtime also is a major challenge, typically happening in greater concentration during start-ups, shut downs, and shift changes. Employees often feel the need to adjust the equipment to the way they believe it will run the best, regularly ignoring standards or "set point" programs. The addition of 50% more shift changes with eight-hour shifts means this problem will multiply as well.

The chaos and downtime lead to lost volume and rising cost-per-unit profiles. Waste also is incredibly costly during shift changes as products may be dumped due to defects from running with too few people or the wrong people. Employees tend to be more distracted at the start and end of their shift, either getting into the mindset of the work in front of them or thinking about what they are going to do after work. This can not only cause errors, but also health and safety concerns around heavy equipment.

Schedule Flexibility

There are three separate types of flexibility that can be helpful to operations:

1. Vertical—The ability to add more hours of operation each day of the week

2. Horizontal—The ability to add more hours of operation at the end of the week

3. Density—The ability to add or subtract head count in a particular area of the business based on operational requirements.

In the world of just-in-time, on demand and low to no inventories, employees are being asked to respond to demand needs since high inventory levels are no longer in place to fulfill that demand. To do this effectively, they need schedules that can flex based on the needs of the business.

On an eight-hour shift, overtime is more difficult because it is only easily done at one time—the end of the shift. It is difficult to ask employees to work a sixth day, giving them only one day off in a week. It is hard to ask them to come in early because they are typically asleep.

They can stay late, but often it conflicts with child-care issues or other commitments. During the week, if there is an operational need, all the employees are already at work, and no additional surge capacity can be called on. Some of these constraints are also true for any type of shift system, but the eight-hour shift is the most limiting of all the typical shift schedules.

Wal-Mart is a classic customer to many manufacturers. They are incredibly large and can make aggressive demands on their vendors (and they do). Wal-Mart may give a three-day lead-time on a product shipment, and vendors, if they want to keep the business, have to be ready to deliver. Density and vertical flexibility may be an operation's only chance at meeting that request. In order to keep carrying costs low, the vendor will probably not have the inventory to cover the order and will have to build.

On an eight-hour shift, a vendor might have to make Wal-Mart wait more than five days until the weekend to get the extra volume with horizontal flexibility. On a 12-hour shift, employees can come in on days off, increasing capacity in the short term (assuming equipment availability). This works much more effectively in today's on-demand world. Operations cannot afford to wait. They have to react.

Poor Management Practices ('Weekend Warrior')

It is no secret that many employees hate working weekends. It is a time for family and friends when "the rest of the world" is not working. When companies require permanent weekend work, they often look for alternatives to having regular, full-time employees work Saturdays and Sundays.

The "weekend warrior shift" is a strategy where an additional group of employees is hired to handle this weekend work. They typically work 12-hour shifts Friday to Sunday or Saturday to Monday.

Although they work 36 hours each week, their pay and benefits are often based on 40 hours. This can be incredibly expensive (at least 10% to over 15% more than regular 40-hour schedules), but is not the most expensive part of this strategy. The third day of work does not really fit easily anywhere because there are already employees covering Monday through Friday creating idle time and pockets of extra employees. Without the weekend warrior system, workers would be required to work 75% of their weekends, and so this is not a great solution either.

The companies that have migrated to longer shift lengths typically do so because they know the weekend warrior is a bad strategy, and with 12-hour shifts employees can increase the number of weekends off by 100% versus eight-hour shifts.

Turnover/Low Employee Morale

As demand for products and services grows, providers must grow as well. To do this efficiently, employers must utilize the massive capital expenditures they have already made and run more hours.

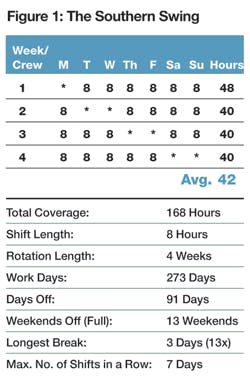

If an operation is currently running five days a week with two eight-hour shifts each day, it is running for a total of 80 hours, or utilizing approximately 48% of the available 168 hours in a week. One way an operation with this schedule could expand is to add a third shift at night. This would give a 50% increase in capital utilization without adding equipment for a total of 120 hours of operation each week. Many operations have done this and declared that they have reached their maximum utilization. In fact, without utilizing the weekend, the best they can do is approximately 71% of the total weekly hours. This leaves 29% of the time where equipment is not used. Why would companies not want to fill the weekends with more production?The eight-hour shift is the problem. Working eight-hour shifts in this continuous environment is often the least desired option from an employee's point of view. On an eight-hour shift where the days on and off rotate so everyone gets equal amounts of weekend time off, employees are forced to work 75% of their weekends. In the most common scenarios (the Southern Swing), they end up working seven shifts in a row three times over the course of a four-week rotation (see Figure 1).

As stated earlier, a large majority of employees hate weekend work and have articulated that to their management teams. The thought of making them work 75% of weekend time off scares managers—and it should!

Many operations today will work large amounts of Saturday or Sunday work on overtime due to seasonal or variable demand, but it is not consistent. However, when asked what their schedules are, employees will probably still say they work Monday through Friday because emotionally they do not want to admit the truth—they are regularly working the weekend. By recognizing the reality of weekend work, management teams can work on alternatives to make improvements to the lives of the shift workers.

However, what if this fear of weekend work is costing your company millions of dollars because of ineffective labor strategies? What if it is costing your company tens of millions of dollars by forcing the construction of new buildings and equipment before you have maximized current capital utilization? Are there alternatives? The easiest answer is "yes." Alternative shift schedules can dramatically improve your ability to utilize more hours in the week without sacrificing employee morale.

In this option employees get every other weekend off instead of every fourth weekend off. All their weekends off are three-day weekends. They get 87 more days off than the eight-hour shifts, and work 182 days a year and get 182 days off. Also, they also never work more than three days in a row in their base schedule. Other iterations of 12-hour shifts can provide up to 17 additional weeks off each year without any loss of pay.

Why must management teams continue to assume that everyone wants to work the same five-day schedule? Although it is right for some people, it certainly is not uniformly right for everyone. To attract and keep the best talent, companies must work to offer better options to shift workers. This not only helps attract the best talent, but helps to keep them once they have arrived.

High Levels of Absenteeism

Absenteeism is incredibly expensive for a variety of reasons. Classic concerns revolve around not having the right skills on the job because another worker, typically not accustomed to the job, is filling in last minute. However, there are several other issues as well. The company still pays the absent employees their benefits for each hour absent.

When employees call off, management does not ask them to cover a percentage of their health benefits and typically does not reduce the amount of vacations or holidays they will accrue over the course of the year. When they fill the vacant spot, the expenses incurred are larger because the fill-in employee is typically paid an overtime rate.

Employees on longer options like 12-hour shifts are absent fewer times because each day missed is worth 50% more lost earnings. This does not mean employees will stop getting sick or have real reasons to call off, but they tend to do it less, therefore causing less disruption.

Cost is not the only issue with call-offs. Employees need time to take the kids to the doctor for check-ups, go to the bank and get the grocery shopping done. Working five days a week, Monday through Friday, may leave only the weekend as the time when these tasks can be addressed. However, the weekend is when everyone else is off, and employees do not like to take that time to do regular chores.

Occasionally they may "break" their schedule in order to free up some time during the week. Employees on longer shifts are also less likely to do this because their schedules allow them to get regular chores done during the week on scheduled days off so they can enjoy their weekends more completely.

Cost to the Employee

The rising cost of gasoline has meant that employees are shouldering a much larger commuting bill than they were just a few years ago. Gasoline prices have more than doubled in the last eight years.

Assume an employee commutes 30 miles to work each way for a total of 60 miles. Assuming their car gets 15 miles per gallon, that is a total of four gallons of gas. If gasoline is $3.50 per gallon, the total cost of each round trip commute is $14. Total workdays on a traditional eight-hour shift are 260. On 12-hour shifts the total workdays are 173. The difference is 87 days. Multiply the 87 by the $14 and that equals a savings of $1,218 every year for the employee. This is a lot of money for anyone, but for someone who may be making $14 an hour, it is more than two weeks pay.

Longer shifts typically provide more opportunities for employees to come in on days off to make additional income. Instead of having a separate crew to handle vacation coverage, management teams can ask employees interested in overtime to come in on one of their many days off. This is not possible on eight-hour shifts as described earlier in "Schedule Flexibility."

Future Shift Workers

Moving forward, employers can no longer be complacent about labor strategies. We cannot afford to keep labor strategies because "this is how we have always done it" or because "another plant does it this way." We need to actually engage with our employees, ask them questions and listen to their responses.

Although the most common schedules in North America contain the eight-hour shift, it is not the best way to move forward. It is time to think strategically as we work to provide a strong job market for future generations.

John Frehse is chief strategic officer for consulting firm Core Practice, New York, and a frequent speaker and author on labor management topics.