Kennametal CEO Sets Course for a Turnaround

In February, Ronald M. De Feo ended his five-week retirement from Terex Corp. (IW 500/149), the Westport, Conn.-based global manufacturer of machinery and industrial products, to take the helm of Kennametal Inc. (IW500/318), a Latrobe, Pa.-based manufacturer of cutting and drilling tools.

The job at hand: to stabilize a company whose revenues had shrunk by over 20% in the past few years.

Recently, IndustryWeek talked with De Feo about his leadership approach and his plan for setting Kennametal back on track.

But first a little background.

With his experience at Terex, where he served as CEO from 1995 until the end of 2015, De Feo brings a leadership approach built on adapting to fluctuating business conditions.

In a 2012 Shingo Prize Keynote, De Feo described his tenure's ups and downs. When he first arrived at Terex in 1992, he noted, "Terex was clearly focused on survival. 'Lean' was not a concept. 'Staying alive' was."

The company's struggles continued through his appointment as CEO in 1995, a time during which, he said, "people were an expense, not an asset. We were cash poor; it was whatever we needed to do to pinch pennies and drive shareholder value. And stay solvent."

By decade's end, however, following a strategy of buying and selling businesses, the company had grown to a $2 billion company, from $300 million in 1996. "We were a holding company, but we had outgrown our structure," De Feo recalled. "We needed a plan."

That plan arrived in 2001, with the fortuitous acquisition of Genie, with its Toyota Production System-based management philosophy. It was then, De Feo said, he began redirecting the company "from being a serial acquirer and holding company to a true operating company with a process for--and commitment to--systemic growth and operational excellence."

Then came the Great Recession of 2008, and a 50% drop in sales in 2009.

De Feo course-corrected: "We didn't abandon our lean journey... the global crisis took precedence. First we had to patch our leaks."

"But we remained committed to our principles. We continued to develop a central repository of organizational knowledge and lean thinking at a pace that the organization could handle."

By 2012, the company had refocused on operations and renewed its lean journey, and looked forward to the next few years of "rebuilding and recalibrating."

In his Shingo speech, De Feo noted the big reason for his success: "I've been CEO this long because I am committed to the long haul and I'm willing to destroy what I built yesterday, regroup and begin again toward the greater good. That's what we did after the Genie acquisition and after the recent financial crisis."

Now, starting anew at Kennametal, De Feo is putting his leadership approach to a new test.

Servant Leadership Principles Remain Critical

Let's start by having you describe your leadership approach.

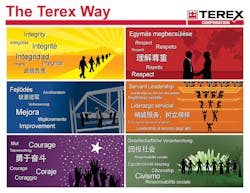

I’d describe my leadership style pretty simply. One: It’s values-based, and the values that I fundamentally believe are critical includes servant leadership. In other words, the organization doesn’t work for me, I work for the organization.

Of course every organization has to be rooted in integrity, values and respect. Those are pretty critical things leadership-wise for me.

I also principally believe in the three legged stool. The three-legged stool consists of leg one: customers. I think we get up every day trying to demonstrate that we offer customers a value-proposition that’s better and different than our competitors or their alternatives.

Second, I think we have an obligation to provide shareholders with a fair return for the investments that they make--and I would include all stakeholders in that, including the communities that we serve.

Third, I think we owe the team members who are a part of the enterprise a fair and reasonable compensation and a level of job security if we can achieve it. That gives them confidence that their investment in us is worthy of a long-term commitment of hard work and ingenuity.

That three legged stool is balanced by an equal emphasis on all three. If you over-emphasize the customer, by either offering unusually low prices or aggressive promotional programs, the stool will fall over because the shareholders won’t be happy.

If you over-emphasize the shareholders, and do everything just to create the highest stock price at a point in time, you’re probably not going to do well by your team members and your customers.

If you create such an environment where fun and games is the way to go to work, because it’s all about the team member, it’s unlikely you’ll have enough edge to really do well for shareholders and for customers.

So [my leadership is based upon this] three-legged stool, founded upon a set of values that includes servant leadership, respect and integrity.

From where did you get that?

Through many years of evaluating how organizations work, then a process at Terex to really try to synthesize it, and a little bit of an analysis at Kennametal, to see what it needs. It’s pretty basic, but it needs to be emphasized.

All too often, CEOs emphasize, "We’re a customer-centric company." Well, of course you have to be customer centric, but does that mean to the exclusion of the people who work for you or of the shareholders?

Things have to be kept in balance. In today’s hotly contested political environment everyone wants to create a black-and-white scenario, where it’s either one way or another. The reality of life is, it’s all about ambiguity.

You know, we’re never quite as fit as we want to be, we’re never quite as young as we used to be. We have to live in this world where perfection is an aspiration but unlikely to be a reality.

So you’re a bit of a realist?

I think realism is business. If you’re not a realist in business, I think you’re a dreamer. There’s a place for dreamers, but, for the most part, for businesses that make things, cut things, bend things, build things, you’ve got to look at the real world with a clear-eyed view of what your pluses and minuses are, and what your capabilities are, and work every day to make it better.

Leading a Kennametal Turnaround

What you’re facing now with Kennametal, you’re on the rockier side of things, similar to when you started at Terex...

This is a cakewalk compared to Terex.

But you’re dealing with rapid market changes that have hurt Kennametal. How does your leadership approach help you deal with the rapid change you need to make at the company?

I think energizing an organization to change is the function of leadership. If you don’t need to change, then everything must be o.k., and if you think everything is o.k., then you probably ought to be retired.

My view of Kennametal is that we have a very good company that should be a great company. We have the ability to do that within our own capabilities. So Kennametal has great products, a great history, terrific technology, and I think an excellent brand name.

On the other hand, we’re facing challenging markets--energy, natural resources, currency, developing markets weakness--so we’ve gone through a decade where we were in a rapid growth period and now a rapid declining period. Companies need to be flexible in that environment, and companies need to get out in front of their cost structure in that environment.

Kennametal was more bureaucratic than it should have been, was more siloed than it should have been, was less entrepreneurial than it needs to be.

What I’m here to do is turn that around into a leaner, more focused, more entrepreneurial and higher-spirited organization.

For an old guy that sounds like a big job, but, you know, I think the passion still exists within this enterprise. It just needs to be harnessed and focused.

And what about the cuts?

We’re taking a 1,000 people out of the organization.

How are you balancing the need for downsizing with your belief that you owe the best to your employees? Aren't you between a rock and a hard place?

I might be naïve, but I think the morale at Kennametal today is head-and-shoulders better than it was six to nine months ago. I think this is a reality for the organization. I’ve been very specific and very direct with the organization. I communicate regularly and often about where we are.

One of the sad things about leadership, sometimes, is that they like to paint a rosy picture. I think leaders should be optimistic, but realistic. From the day I took over here, I started to communicate about some of the tough challenges and changes that this organization faces.

So the way you get credibility on this front, if you’re going to reduce employment by a thousand people, is to start at the top of the organization. So that means at the executive leadership team. We changed four of the top nine of the executive leadership team. We retired a couple and changed out a couple of others. That’s a big change to reduce costs at the top of the organization.

Then we focused on the 100 top-paid people in the company. So 25% of the top 100 paid people at Kennametal are no longer employed here; that’s a very significant change.

That's a lot of leadership change...

Now, in order for that to work, you’ve got to eliminate work, which means you have to focus. Stop doing some things. By making these changes you can then dig deeper in the organization and examine what needs to stop.

We offered a voluntary separation program. We asked people, giving them fair treatment, would you like to continue working here or not? We had a lot of people accept that voluntary retirement plan. So we did it with respect and dignity for people.

And then the last several hundred of the thousand people will have to come out by going in and separating some workers from the company. It’s really unfortunate but, for the remaining 11,000 people to succeed, we’ve got to have substantially lower costs and that means, frankly, fewer jobs.

The company’s 21% smaller today than it was a year ago, so that’s a reality check.

You don’t need the same number of people because you’re building less product.

You talk about communicating a lot. What specifically do you do?

When I first started, I went to some of our major facilities and I held town hall meetings. I talked straight with people about what’s working and not working, and why I was here.

Why does a guy who’s been a CEO for 22 years, who’s been on the board since 2001, take the job as CEO of Kennametal? Frankly, it’s not because I want the money. I was highly compensated at Terex. I was very happy with my five-week retirement. But I believe that this is good company where a little bit of leadership change can make a big difference.

So to answer your question: You do town hall meetings. Also, I have a session that I introduced from the day I walked in the door, called “Let’s Talk,” where I do a video, and that video deals very specifically with issues going on in the company. It gets put on our internal communication systems, which goes to thousands of our team members. We track it, we know who clicks on it; we know who watches it.

I do it every three to four weeks. I ask for feedback; at every one of our “Let’s Talk” sessions, I’m asking for emails. I answer every email personally. I don’t get that many, surprisingly. But the ones I do are thoughtful, articulate and deserve a response from the CEO. After all, if I’m going to talk about servant leadership I have to walk the talk.

Organizational Change, Lean Management and Automation

What in addition to communication is critical to change management?

I think it’s actually changing the organization. We changed from a matrix organization to a profit-and-loss organization, so now I have three business leaders who are completely responsible for the product, the pricing, the marketing, the selling, the design--every aspect of their business.

Historically, there were really glorified sales leaders. We had a separate organization for manufacturing, a separate organization for engineering, a separate marketing organization, each of whom reported independently to the Chief Executive Officer. That was a difficult structure for success.

So by making that organizational change, I can now get alignment from the staff groups--chief financial officer, HR, legal, etc.—along with my business leaders. It’s pretty clear that the business leaders are responsible for driving customer satisfaction, driving the profit and loss of the organization, and that all the support organizations are now responsible for helping those business leaders.

So you change the organization, you change the communication, you actually walk the talk and if you do it consistently, people start to say “I get it. I understand what this is about.”

Frankly, Patricia, I know the least about this business of any business I’ve ever managed. But there are a lot of people who know a lot about it. Why should I be making small decisions about many aspects about this business? Those decisions need to be deeper in the organization, much closer to where the issues are. That’s what changing the organization does, and that’s what a mentality of servant leadership encourages.

And then time. Don’t forget about time; consistency and time. You need to tell people, this isn’t going away; this is not the flavor of the month. Get on the bus or get off the bus. It’s pretty simple.

How does Lean management fit into your leadership approach?

Kennametal has been very strong in lean principles over the years. But I would say we need to reconstruct our Kennametal Business System, and that’s going to take us some time because, in my opinion, we have a lot of lean initiatives, and some excellent lean accomplishments, but it's not been done from an integrated business perspective. For example, we have lean continuous-flow processes, but our manufacturing process is batch oriented.

We need to modernize our manufacturing facilities with new technology, not just with lean thinking.

Lean thinking can get you a long way to taking waste out of the system, but you can’t afford $20-an-hour workers taking little inserts and putting them into plastic packages. I don’t care what lean system you work on, that’s going to be an inefficient way to package your inserts, when you can automate it, when you can buy machinery. The machinery also will inspect the product with a laser inspection, and you can deliver better quality at a lower cost.

We have to balance lean principles with modern manufacturing techniques, and I think frankly that’s what the best lean companies have always done. I think Kennametal did a good job, but not a great job, finishing the task.

So how will you pursue lean at Kennametal. Will you take your top 100 people off to a fancy place for visioning, like you did at Terex?

Probably not. We’re going to start with the top of the company, the structure of the company where we have a new leader who is head of supply chain and strategic sourcing. He and his team are going to help develop the next generation Kennametal Business System. We’re going to do that as a team, we’re not going to do it from the top down.

But I don’t have the level of urgency on that, because I think we’ve got so much more basic work to do. Let’s get the 1,000 people out, let’s get the work out, let’s reduce the amount of specialty work that we do, simplify our product line, let’s begin to modernize and invest in new manufacturing automation initiatives. Let’s get some of that stuff done, and then we’ll come back to bringing lean back into the organization.

We still have a lot of green belts, we still have a lot of people who do Kennametal lean events, that’s still a part of the company’s culture, but I think we’ve got to figure out some other things first.

What technologies are at the top of the list, that you need to bring into the factories.

Just think automation. Automation. There it is. We handle things multiple times, our ovens to dry things out take too long, our processes don’t use the latest flow techniques, and you know those are all opportunities. Frankly, I think my competition probably already does those things, or some of those things, but now I have an opportunity to take the next generation of technology and advance the cause.

The Importance of Focus, Passion & Planning

What do you mean when you say “make sure the company is focused?”

Well when you have nearly 60,000 customers over 100,000 SKUs, your sales organization acts a bit like a deli counter. I think you can concentrate the work of those that sell and those that make in a more cohesive, organized and structured way.

That’s not to say we’re going to stop doing specials, or we’re going to stop doing engineered solutions, but I think we can be much more planful and concentrated in the things that really drive the value for the organization.

How would you do that?

If we come out with a new product, we need to supercede the old product, not keep it around just in case somebody wants it. If we are managing a sales territory, we need to decide which customers should buy from distributors versus which customers we should ship direct.

Our history has been all about selling customers direct. It’s not necessarily the best thing to sell them all direct. In fact 65% or so of the total market buys through distributors. For our industrial business, it’s 50% or less that buys through distributors, so we’re a bit of an outlier in our emphasis on direct sales.

If the biggest metal cutters want to buy direct from us, we’re going to sell to them direct. But there are a lot of other machine shops out there in the world that would love to have Kennametal products, and they should be able to access them quickly through local distribution.

So you want to increase your distribution business?

Our distribution business is good, but it needs to get better. And we also need to sell multiple brands. We have tried to concentrate on the Kennametal brand historically, but we also have Widia as a brand, and Widia has a great history; it’s been in existence for over 90 years. We’ve owned it since 2003 and done very little to grow it.

So part of the change that I initiated was to separate the brand and appoint a president, and have a president of that brand directly report to me, as opposed to being a part of the Kennametal brand team. That’s focus. I want to focus on the Widia brand because it’s got great value and excellent potential. So that’s the kind of thing I mean by focus.

What else do you believe is necessary in leading and change management?

I think success will be a result of the passion people have for their future. You cannot achieve success without passion. We’ve got a lot of people who are passionate for the product. We have to have our people be more passionate for the enterprise.

They may love the product, but hate the company. We need people to love the company and love the product. People have told me that Kennametal is a company that has great products, but it’s hard to do business with. I want Kennametal to be easy to do business with, with great products. And I think that will unlock a lot of potential for us.

How do you drive passion?

You demonstrate it. I’ll give you an example. Last night we had nearly a thousand customers come to an event here. I stood at the front door and shook everyone’s hand as they entered. That’s how you drive passion. You demonstrate it, and you encourage others to take the same ownership of that customer relationship.

How do you demonstrate it to the workers who are at the factories?

You get a leadership team who believes the same things and walks the talk. And when you go visit those facilities, you take the time out of your day and have an all-employee meeting, as I did in Solon, Ohio, not too long ago. That’s what you have to do.

Then when people ask you tough questions, you answer them straightforwardly. An employee at Solon asked me the question: Why do we have this problem? This is an hourly worker asking why are we always in this fire drill for getting this particular thing done.

I answered it pretty directly: the four “P’s,” piss poor prior planning.

Planning is at the root of all good activity. You have to plan your future. Someone once told me that planning is always best done in advance.

Now, that answer doesn’t solve that problem, but it tells the team that I’m not going to sugar-coat the issues. We’re going to address them head on.

And I think frankly, people are looking for honesty in their leaders.

About the Author

Patricia Panchak

Patricia Panchak, Former Editor-in-Chief

Focus: Competitiveness & Public Policy

Call: 216-931-9252

Follow on Twitter: @PPanchakIW

In her commentary and reporting for IndustryWeek, Editor-in-Chief Patricia Panchak covers world-class manufacturing industry strategies, best practices and public policy issues that affect manufacturers’ competitiveness. She delivers news and analysis—and reports the trends--in tax, trade and labor policy; federal, state and local government agencies and programs; and judicial, executive and legislative actions. As well, she shares case studies about how manufacturing executives can capitalize on the latest best practices to cut costs, boost productivity and increase profits.

As editor, she directs the strategic development of all IW editorial products, including the magazine, IndustryWeek.com, research and information products, and executive conferences.

An award-winning editor, Panchak received the 2004 Jesse H. Neal Business Journalism Award for Signed Commentary and helped her staff earn the 2004 Neal Award for Subject-Related Series. She also has earned the American Business Media’s Midwest Award for Editorial Courage and Integrity.

Patricia holds bachelor’s degrees in Journalism and English from Bowling Green State University and a master’s degree in Journalism from Ohio University’s E.W. Scripps School of Journalism. She lives in Cleveland Hts., Ohio, with her family.