In both the automotive and aerospace industries, engineers have used product models to better visualize designs and plan their manufacturing accordingly.

But Northrop Grumman Corp. took it to a far larger scale recently by using 3-D CAD software to develop a detailed design for the Gerald R. Ford (CVN 78) Navy aircraft carrier. Just how vast is the scale? Consider that the ship is broken down into over 400 different design zones and constitutes more than 3 million parts.

According to Michael Shawcross, vice president of aircraft carrier construction programs at Northrop Grumman, the CVN 78 is the Navy's first aircraft carrier to be completely designed using a 3-D product model.

In November, Northrop Grumman completed the detailed design phase of the 3-D product model using CATIA from Dassault Systemes. The CVN 78's product model includes the definition of the ship's geometry and technical definition of the ship's parts, including the procurement, planning and manufacturing data.

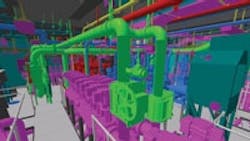

Above: A virtual image of the Gerald R. Ford Navy aircraft carrier's pump room using CATIA software from Dassault Systemes. Below: An artist's rendering of the Gerald R. Ford (CVN 78) Navy aircraft carrier, which will be made from more than 3 million parts.

The software helped to identify areas of overlap, where, for example, piping layout might have interfered with maintenance criteria.

While the CVN 78 will continue to evolve, says Shawcross, it is now at the stage where the initial design data is complete and the entire carrier exists in a virtual environment. As a result, construction teams in its Newport News, Va., shipyard can virtually walk through the carrier's spaces before actually starting the physical build.

The CVN 78, which is the first ship of its class, is scheduled to be delivered to the Navy in 2015.

See Also