America's Advanced Industries: New Challenges for a New Manufacturing

Manufacturing has changed.

Yesterday's concept of the dark, dirty, dangerous and dull manufacturing industry – a siloed industry of production in isolation from service and technology – no longer bears any resemblance to the vibrant sector it is today.

Digging out of the recession these last few years with the help of advanced robotics, 3-D printing and "digitized everything," the lines between technology, business and manufacturing have been blurred almost completely.

The result is a new kind of manufacturing industry – STEM-based and overwhelmingly broad – that has once again reclaimed its place as the driver of the U.S. economy.

Special Report: IndustryWeek's Coverage and Analysis of "America's Advanced Industries"

This has been a recurring theme on the pages of IndustryWeek for years, but the full power of the transformation was just revealed this morning in an explosive new report from the Brookings Institution on "America's Advanced Industries."

The report links 50 otherwise isolated industries – including 35 from the manufacturing sector and 15 more from energy and service – into one advanced industries super-sector in order to measure the real economic impact manufacturing and production in all its forms is having today.

"Technology is exploding," explains Mark Muro, a senior fellow and director of policy for the Metropolitan Policy Program at Brookings. "Manufacturing is turning out to be a very different, much more dynamic and high technology pursuit that is at the center of all sorts of things that are going on today."

This recasting of the sector paints an interesting picture of manufacturing in the 21st century – a truly high-tech endeavor that pulls far more weight in the economy than anyone even suspected.

According to the report, every new job falling into that advanced industries sector creates 2.2 jobs domestically. That means that of the 12.3 million workers currently employed in the super-sector, "another 27.1 million U.S. workers owe their jobs to economic activity supported by advanced industries through their supply chains and their employee's consumption."

That is a powerful effect.

"When you include both direct and indirect employment through this multiplier effect, you arrive at nearly 1/5 of the nation's economic activity attributed to this relatively modest-sized set of 50 industries," Muro notes. "Its importance is beyond arguing."

While all of this is certainly good news for manufacturing, it also underscores some of the real and imminent challenges facing the American workforce that serves it: To keep up with this growing and diversifying high-tech industry, we need a workforce with advanced STEM (science, technology, engineering and mathematics) skills and high-tech experience to drive it.

Forging a STEM Workforce

"We have a massive challenge in having quickly trained, precisely trained people relevant to a whole range of production jobs," Muro says. And these are unequivocally good jobs, too, he adds – high paying jobs in exciting, competitive industries.

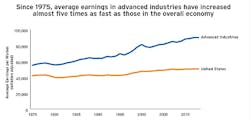

According to the Brookings report, wage growth in the advanced industries far outpace anything outside it. In 2013, it measures the average advanced industries salary to be around $90,000, at least twice as much as the average outside the sector.

To a large part, that is to be expected. This industry, the report figures, consumes 80% of the nation's engineers and about half of the country's science, engineer, computer and mathematics workforce.

With the technical skills they require and the value these workers generate – $210,000 annually versus $101,000 outside the sector – it's not exactly surprising that they would be paid more.

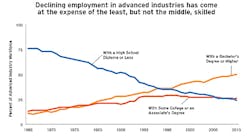

But what is surprising is that many of those high paying jobs don't require the advanced degrees you'd expect.

"These industries provide not only very high-paying jobs themselves, but they also provide a surprising degree of accessible employment as a group," Muro notes. In fact, he adds, half of the jobs in the super-sector only require middle skills or sub-bachelorette degrees.

So far, all of this looks great – recast into the advanced super-sector, manufacturing looks robust and growing, its workers are well-compensated and require anything from basic to advanced tech skills.

But this current state is far from stable. There is still the looming threat of the skills gap to tackle.

Taking on the Skills Gap

While not every job in this industry requires advanced degrees, the Brookings report calculates that 60% of the jobs posted for it are for STEM workers, compared to 34% outside the sector. Those job posting, it states, remain unfilled longer, indicating a major supply problem in the workforce.

And that's no surprise.

STEM graduates at any level are pretty dismal in the U.S., which ranks 23rd among developed nations on that account. Worse, the report notes, Finland, South Korea, the UK, New Zealand, Germany, Portugal, Poland and the Slovak Republic all have STEM graduation rates 50% higher than the U.S.

And that is a major problem for a country so reliant on these advanced industries.

To combat that issue, Brookings included in the report a number of recommendations for both the private and public sector.

Private Sector:

"Companies, to start, should reinvigorate their efforts to develop the talent they need in both the short and long term," the report recommends. "The demands of renewed growth amid persistent skills gaps necessitate a stronger focus on retention and internal training even as firms seek out new opportunities in recruiting talent."

To do that, the report recommends the following:

- Invest in strong talent management and retention strategies.

- Implement more flexible hiring standards.

- Expand recruitment efforts to include community colleges and career and technical education programs.

- Get more involved in modernizing their local workforce development system.

- Partner with local educational institutions to develop the next generation of skilled STEM workers.

Public Sector:

"The imperative for private-sector initiatives and involvement notwithstanding, it remains the public sector that delivers the most formal education and workforce training in the United States," the report notes. "Significant change is needed if the nation is to ensure the advanced industries sector has access to the workers it needs to thrive."

It recommends the following steps:

- Improve accountability and encourage innovation in education, particularly in schools that serve low-income students.

- Increase investment in applied STEM education at all levels.

- Articulate and implement a strong vision of aligned advanced industry-related training and education.

- Facilitate and support "bottom-up" efforts to align labor supply with demand regionally.

- Attune educational curriculum to regional demand for STEM skills.

- Take steps to boost student completion rates.

- Increase the number and quality of STEM learning-opportunities in high school.

- Improve the quality of teaching in STEM disciplines in secondary and middle school.

- Ensure that all students have equal access to high-quality schools.

- Expand access to high-quality early education.

To read more about these tips or about America's Advanced Industries as a whole, check out Brookings' full report at www.brookings.edu.

About the Author

Travis M. Hessman

Editor-in-Chief

Travis Hessman is the editor-in-chief and senior content director for IndustryWeek and New Equipment Digest. He began his career as an intern at IndustryWeek in 2001 and later served as IW's technology and innovation editor. Today, he combines his experience as an educator, a writer, and a journalist to help address some of the most significant challenges in the manufacturing industry, with a particular focus on leadership, training, and the technologies of smart manufacturing.