When Motorola Solutions Inc. wanted to test the viability of an electronic name badge designed for workers in manufacturing and retail operations, the company developed a prototype and let two large retailers put the device through its paces.

Based on that feedback, Motorola Solutions (IW 500/123) decided to move forward with development, and earlier this year launched the SB1 smart badge -- a wearable electronic device that serves as an employee name badge as well as a bar-code scanner and two-way radio.

See Also: Manufacturing Innovation & Product Development Strategy

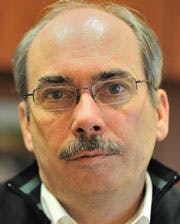

"We don't have any predecessor product to this device, so it was a huge risk," says Graham Marshall, director of global design research for Schaumburg, Ill.-based Motorola Solutions. "We were putting pre-production stuff in the hands of customers and letting them test it out live."

That kind of customer-led research, though, is standard operating procedure at Motorola, which makes communication infrastructure, devices and software for law enforcement agencies, manufacturers, retailers and other business and government customers. The firm reported sales of $2.2 billion in the third quarter. Marshall and his research team, who work in Motorola's chief technology office in Holtsville, N.Y., have visited 170 customers this year to assess their needs and determine how Motorola Solutions can adapt new and existing products to customers' processes.

"We don't do Web surveys. We don't do focus groups," Marshall says. "We go to the customers. We interview the IT guys, the operations guys, the users. We do ride-alongs. We do observational research.

"We're connected tightly with the customers. For us, that's where innovation comes from."

Marshall notes that his philosophy around innovation has been driven by a candid quote from a Motorola Solutions customer, who said: "It's really nice that you're making the devices smaller, but what I really want to know is where my next 20% productivity [improvement] is coming from."

"Ultimately, it's not about the product," Marshall says. "It's about what the customer is trying to do."

That philosophy came to life when Motorola Solutions was developing the next generation of its MC9500 industrial mobile computer, frequently used in warehouses and distribution centers.

The conventional thinking for the next iteration of a high-tech product is to make it smaller, lighter and faster. But through its customer research, Motorola Solutions discovered that "the real pain point for the customers wasn't the product and the features and the functionality" -- it was the fact that chargers for mobile computers and batteries are designed to work with only one device.

"You can imagine a major courier has thousands upon thousands of depots, and they have backrooms where they're charging 60 to 80 of these devices," Marshall explains. "So anytime there's a new device, they have to send in carpenters and electricians to every single depot to build new shelving units and set up new charging stands.

"So we realized that they were actually spending more money in managing the device in the backroom than they were on the device itself."

To address this issue, Motorola Solutions developed what it calls a "form-factor-agnostic universal accessory system" for its MC9500-K mobile computer. The MC9500-K features an I/O interface that connects to the universal cleat on cradles, chargers, magnetic stripe readers, cables and other accessories, eliminating the need to purchase new accessories to accommodate the device.

Motorola Solutions also created a universal wall-mount bracket, enabling customers to install the MC9500-K and future-generation mobile computers without hiring carpenters or electricians.

"If you wanted to innovate around just the product, you never would have seen the enormous opportunity in the backroom solution," Marshall says.

Through its research, the company also discovered that customers' backroom operations lack formal systems to determine the health of their batteries, leading to complaints about battery life. Although customers said they needed bigger batteries, "the problem was they needed a way to manage the batteries," Marshall points out.

Motorola Solutions responded by developing a mobile-computer battery with an intelligent graphical display that shows the state of the battery charge as well as the state of the overall battery health.

"If you're talking about innovation and [building] a culture of innovation, for me it's about how closely you're tied to your customer and what your customer needs are," Marshall says. "Because you're really at the service of what the customer is trying to do.

"You don't want to think about your product and your portfolio and protecting your market share. You want to think about what your customer needs to grow."

About the Author

Josh Cable

Former Senior Editor

Former Senior Editor Josh Cable covered innovation issues -- including trends and best practices in R&D, process improvement and product development. He also reported on the best practices of the most successful companies and executives in the world of transportation manufacturing, which encompasses the aerospace, automotive, rail and shipbuilding sectors.

Josh also led the IndustryWeek Manufacturing Hall of Fame, IW’s annual tribute to the most influential executives and thought leaders in U.S. manufacturing history.

Before joining IndustryWeek, Josh was the editor-in-chief of Penton Media’s Government Product News and Government Procurement. He also was an award-winning beat reporter for several small newspapers in Northeast Ohio.

Josh received his BFA in creative writing from Bowling Green University, and continued his professional development through course-work at Ohio University and Cuyahoga Community College.

A lifelong resident of the Buckeye State, Josh currently lives in the Tremont neighborhood of Cleveland. When the weather cooperates, you’ll find him riding his bike to work, exercising his green thumb in the backyard or playing ultimate Frisbee.