Too many companies are underutilizing their investment in warehouse management systems (WMS), according to a best practices survey conducted by the Supply Chain Consortium, which represents consumer goods manufacturers and retailers. "Although companies are implementing these solutions to enhance operations, too many do not take their investment to the next level by continually evaluating how well they employ their WMS and seeking improvement opportunities," observes Tom Singer, a principal with supply chain consulting firm Tompkins Associates.

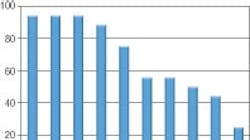

Although most WMS solutions are being used to support receiving, putaway, picking and shipping, the survey indicates that companies have been slow to adopt other functions within these systems, such as cycle counting, packing, slot management, labor management, dock management and yard management.

| By The Numbers: Warehouse Management 5 Companies that use warehouse visibility systems are five times as likely to have lowered their warehousing costs as all others. 3 Those that use distributed order management systems are three times more likely to have reduced cycle times. 2 Users of automated dock management systems are twice as likely to have reduced cycle times as those using a manual system or no system. Source: Aberdeen Group |

Functionality Used In A WMS

See Also

About the Author

Dave Blanchard

Senior Director of Content

Focus: Supply Chain

Call: (941) 208-4370

Follow on Twitter @SupplyChainDave

During his career Dave Blanchard has led the editorial management of many of Endeavor Business Media's best-known brands, including IndustryWeek, EHS Today, Material Handling & Logistics, Logistics Today, Supply Chain Technology News, and Business Finance. He also serves as senior content director of the annual Safety Leadership Conference. With over 30 years of B2B media experience, Dave literally wrote the book on supply chain management, Supply Chain Management Best Practices (John Wiley & Sons, 2010), which has been translated into several languages and is currently in its second edition. He is a frequent speaker and moderator at major trade shows and conferences, and has won numerous awards for writing and editing. He is a voting member of the jury of the Logistics Hall of Fame, and is a graduate of Northern Illinois University.