Innovation is the lifeblood of many manufacturing companies, and such is the case for medical technology firm BD (Becton, Dickinson and Co.). To that end the company, which produces a broad range of medical supplies, devices, laboratory equipment and diagnostic products, has rolled out a company-wide product development system as well as the Design for Six Sigma methodology. And its use of simulation in product development is on the rise.

Demand for simulation is growing for good reason, explains Anita Bestelmeyer, BD's computer-aided-engineering (CAE) manager. She says that employing simulation reduces the number of physical prototypes that are needed, which helps lower costs and get innovations to market more quickly. Equally important, simulation helps to ensure the robustness and quality of the products being developed. (Such concerns are nearly universal among companies these days. A 2008 Aberdeen Group study reported that the top pressures driving changes in how product performance is improved include shortened development schedules, a need to reduce development costs and a demand for increased product quality and reliability.)

The benefit of simulation is a message Bestelmeyer is helping spread throughout BD.

Her message is working. Demand for simulation in the product development process not only has grown, but also the simulation group is being brought into the process sooner. In the past, for example, some projects were brought to the simulation group only after "something wasn't working right," Bestelmeyer says. If something wasn't working correctly, it wasn't discovered until physical prototypes and testing already had been completed -- which means the problems were arising late in the product development cycle. "At that point there's less you can do because the design is kind of frozen," she says.

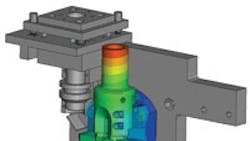

Heat tolerance of a BD flow cytometry system laser unit is analyzed in Abaqus FEA software from Dassault Systemes' Simulia brand. The FEA solution shows a typical thermal stress or thermal displacement plot, with the color contours indicating the range of stress or displacement on key components.

The CAE manager says the majority of BD's simulation work is for its medical business group, which develops products such as needles and syringes and drug-delivery systems. The company works with a variety of simulation technologies, including the Abaqus finite element analysis suite from Simulia for structural analysis to optimize part performance and structural integrity. Structural analysis is the largest of three focus areas in which BD's CAE Analysis performs simulations.

The other areas of focus are injection-molding simulation, to predict manufacturability, and fluid dynamics, to optimize fluid flow. BD employs Moldflow and Fluent and CFX software for these simulations.

Bestelmeyer also works with software partners to both better understand and develop their capabilities. In a September 2008 interview for Simulia, she explained one such effort: The collaboration, she noted, was to investigate problems such as device interactions with biological tissues.

See Also

About the Author

Jill Jusko

Bio: Jill Jusko is executive editor for IndustryWeek. She has been writing about manufacturing operations leadership for more than 20 years. Her coverage spotlights companies that are in pursuit of world-class results in quality, productivity, cost and other benchmarks by implementing the latest continuous improvement and lean/Six-Sigma strategies. Jill also coordinates IndustryWeek’s Best Plants Awards Program, which annually salutes the leading manufacturing facilities in North America.

Have a story idea? Send it to [email protected].