IW50 Profile: Steel Dynamics -- Nuggets of Opportunity

None of the 2009 IW 50 Best Manufacturing Companies came close to matching Steel Dynamics Inc.'s (SDI) 84% revenue growth in 2008. In just its 15th year of existence, the Fort Wayne, Ind.-based manufacturer of carbon steel products posted record revenue of nearly $8.1 billion in 2008 -- thanks to several acquisitions and higher average transaction prices for steel products, according to Chairman and CEO Keith Busse in the company's 2008 annual report.

Founded in 1993, SDI attributes its rapid ascent to the company's ability to seize on "business opportunities in our areas of technical expertise, through building new production facilities and acquiring others," according to its Web site. While SDI proved to be mortal in the first half of 2009 -- posting losses in the first and second quarters -- the company rebounded in the second half of the year, and the steelmaker continues to pursue new business opportunities at a time when other steel companies are hunkering down.

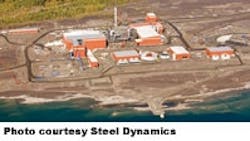

Case in point is SDI's investment in a new iron nugget plant at the Mesabi Iron Range in Hoyt Lakes, Minn. The $275 million facility is part of the "Mesabi Nugget" project, a partnership between SDI and Japanese steel titan Kobe Steel Ltd. that aims to create the world's first commercial-scale iron nugget operation. (SDI has an 81% stake in the project.)

Using Kobe Steel's patented ITmk3 ironmaking process, the new facility will convert iron ore and pulverized coal into 97%-pure iron nuggets that are comparable in quality to "pig iron" -- a feedstock for the production of flat-rolled steel in mini mills -- and produced in a more environmentally friendly manner than conventional ironmaking, according to SDI.

With its Mesabi Nugget plant (pictured above), SDI aims to provide its steel mills with a consistent domestic supply of pig iron. At press time, SDI's Mark Millett expected the plant to begin shipping iron nuggets to SDI steel mills in the first quarter of this year.

That self sufficiency likely will translate into significant cost savings for SDI. With no domestic source available, mini-mill steel producers such as SDI currently purchase pig iron from foreign suppliers. While pig iron prices have ping-ponged from heights of more than $800 per metric ton in 2008 to roughly $300 per metric ton in 2009, according to Millett, SDI believes "that there's a floor in the pricing of commercially available pig iron, and we're at it today."

"As we look ahead, we see developing countries and emerging markets increasing their demands for iron, and we would expect prices for these global commodities to rise," Millett says.

Consequently, SDI believes that the timing of Mesabi Nugget is perfect: Once Mesabi Nugget begins mining its own iron ore from a 6,000-acre taconite mine at the site of the new plant, the company expects to be able to produce pig iron at a cost of $350 per metric ton.

Millett expects that the Mesabi Nugget operation will not only be a consistent domestic supplier of iron nuggets and a more cost-effective way to provide those materials than importing pig iron, but also will provide a growth opportunity by selling the nuggets to other mini mills and to foundries.

IndustryWeek selects the IW 50 Best Manufacturing companies each year based on a formula applied to the IW U.S. 500 list of the largest publicly held manufacturers in the country. View all IW 50 manufacturers and associated content. Interested in information related to this topic? Subscribe to our weekly Leadership Insights From The IW 50 eNewsletter.

About the Author

Josh Cable

Former Senior Editor

Former Senior Editor Josh Cable covered innovation issues -- including trends and best practices in R&D, process improvement and product development. He also reported on the best practices of the most successful companies and executives in the world of transportation manufacturing, which encompasses the aerospace, automotive, rail and shipbuilding sectors.

Josh also led the IndustryWeek Manufacturing Hall of Fame, IW’s annual tribute to the most influential executives and thought leaders in U.S. manufacturing history.

Before joining IndustryWeek, Josh was the editor-in-chief of Penton Media’s Government Product News and Government Procurement. He also was an award-winning beat reporter for several small newspapers in Northeast Ohio.

Josh received his BFA in creative writing from Bowling Green University, and continued his professional development through course-work at Ohio University and Cuyahoga Community College.

A lifelong resident of the Buckeye State, Josh currently lives in the Tremont neighborhood of Cleveland. When the weather cooperates, you’ll find him riding his bike to work, exercising his green thumb in the backyard or playing ultimate Frisbee.