Unchained Melody: A Lean Value Chain Starts with Demand Management

You know you have a demand management problem if production and supply are always out of sync with incoming orders. You know you have a problem if, even with long lead times, you can't meet customer delivery expectations. Or if, despite high inventory levels, you're missing out on potential sales because products are out of stock. In today's marketplace and uncertain economy the cost of such miscues -- obsolete inventory and lost customers -- can be high.

A lean value chain begins with the customer. While many people say they understand this precept in theory, many lean initiatives start off on the wrong note by focusing internally on the factory floor or back office. Unfortunately, volatile order volumes can wreak havoc with any attempt to reduce work-in-process inventory and create a steady material flow. In many cases this volatility is self-inflicted, which is where demand management comes in.

Demand management helps everyone in the company see true customer demand. In the retail sector true customer demand is the point of sale when the consumer hands over his or her cash or credit card. In other sectors it's the ultimate consumption point that should trigger replenishment back through the fulfillment chain starting with the manufacturer and on through distribution.

Demand management harmonizes the activities of sales and marketing -- which tend to focus on orders and dollars -- and operations -- which is all about output and units. The goal is to better align sales policies such as promotions, pricing structures, packaging and delivery frequency -- which tend to increase demand volatility -- with production capabilities. Removing such volatility reveals actual capacity requirements, reducing capital needs and improving service levels. Not overproducing and removing extra inventory eliminates labor costs that relate to handling that excess inventory.

Demand Segmentation

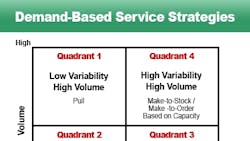

Most approaches to production planning treat all products the same. By analyzing and segmenting products, a company can optimize planning, control and manufacturing. Plotting the volume and variability for each product segment can lead to more predictable and responsive production processes, and reduce inventory at the same time. Demand segmentation will determine, for example, if a product should be made using a "pull" system, if it should only be produced on a made-to-order basis, or even if it should be discontinued altogether.

On the chart above, product families that fall in Quadrant 1 exhibit steady, high volume demand, making them ideal candidates for a pull system. A low volume, highly variable product that falls in Quadrant 3 suggests a make-to-order strategy. It's also a candidate for discontinuation.

A demand segmentation initiative will also look at production volumes, historic inventory levels, shipment records, and point-of-sale data if it's available. Simply overlaying this data on a graph can make it obvious for everyone to see how promotions, seasonality and other market factors influence demand and production processes.

A Case in Point

When we started working with a national supplier of foodservice products they were continually pushing promotions to stimulate orders. This created the typical peaks and valleys in volume because they had trained their customers to stockpile material and wait for discounts before placing any new orders. Smaller volume customers had to buy full-pallet quantities that took them months to sell. Nobody at this company looked at the point-sale-data that they received from some of their customers. Manufacturing based its production schedule on the sales forecast, which was accurate only 55% of the time. As a result their order fill rate was only 97.7%, despite having 23 to 85 days of inventory.

By analyzing and understanding the demand patterns of different product families, looking at average volumes and variations in demand, managers determined that their own inventory management policies were responsible for creating the sharp spikes in production and shipments. They also discovered that more of their products than they'd previously thought could effectively be manufactured by a pull system. The remaining products consisted of high variability items driven by seasonality or erratic order patterns.

Starting in a single distribution facility, this food service supplier began to break free from its traditional supply-chain structure. They started by using an existing inventory management system to send electronic replenishment (kanban) signals to the factory to signal production. To get to the new stocking levels, manufacturing had to shut down several production lines for three weeks to bleed off the extra inventory. To further smooth out demand, the company changed its sales policies to allow customers to order smaller, less-than-full-pallet quantities. In the end, even though there was less inventory in the supply chain, fill rates improved to over 98.5%. Not having to ramp up and ramp down resources to meet the demand fluctuations reduced variable labor costs by several hundred thousand dollars in just one factory.

By understanding and segmenting your demand, and applying demand-based service strategies to the appropriate customer segments, you too can achieve dramatic reductions in inventory while maintaining or improving fill rates. It starts by getting closer to your customer so that everyone can better understand actual consumption patterns, which comes from sharing point-of-sale data or some other indicator of true demand. Working from such information will optimize inventory levels and reduce working capital requirements for your customers as well. Improved product availability will make them happy because their customers can get what they want.

The more in sync the supply chain is, the more everyone moves to the same demand tune, the higher the returns. The higher the returns the stronger your customer relationships and the less likely that your customers will need to look for alternate suppliers, which should be music to your ears.

TBM Consulting Group, Inc. is the leading provider of LeanSigma consulting and training services in North and South America, Europe and Asia. The company's mission is helping manufacturers and service industry businesses create a competitive advantage to generate significant growth in sales and earnings. http://www.tbmcg.com/en/

Interested in information related to this topic? Subscribe to our weekly Value-chain eNewsletter.