Maximizing the competitive power of production equipment starts with product design. For example, is the product designed to be efficiently manufactured -- as well as effectively used? Product design needs to be connected with process engineering.

Those were just some of the target goals of Geoffrey Boothroyd and Peter Dewhurst when they founded Boothroyd Dewhurst Inc. to market their design optimization software. Today, 24 years later, to continue optimizing the software itself, the company sponsored a user survey and roundtable (Click here for a .pdf). One finding: "The survey results show that companies who stayed focused on reducing part count and assembly time are still reaping huge savings," notes President John Gilligan.

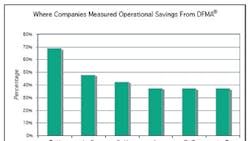

The survey, conducted by Parker Group, also reveals how broadly the users view the software's ability to deliver value beyond the original part-reduction focus. For example, today's Design for Manufacture and Assembly (DFMA) users also identify savings potential ranging from factory floor space reductions to product end-of-life benefits.

But surprise -- while surveyed users realize that the software can deliver much more than part-count reduction, actual participation in reduction efforts lags. One surveyed DFMA user offers a reason: "There is still a misperception that Design for Assembly and Design for Manufacturing are just parts of the manufacturing process," notes Gordon Lewis, project engineer, DaTuM 3D Inc. , Watertown, Mass., a custom design firm. "This optimization concept is much more than that. This analysis capability really has to be ingrained in the total product development and manufacturing process." He says the design function must get involved.

Lewis also points to a widespread staffing challenge. "Few companies seem to be equipped to track these other cost drivers or even appreciate what they are. I'm amazed by how common it is for manufacturing companies to not know their unit costs. When asked, they offer guesses within a broad range -- 30% to 40%."

His conclusion: "Anyone planning a production strategy ought to have this kind of analysis software as part of their agenda. Too few companies today have assigned the multidisciplinary teams required to monitor and plan. Don't expect cost accounting departments to really know what it costs to produce a product."

Lewis adds, "Our DFA analysis has allowed us to accurately forecast the need and cost for assembly tooling and test fixtures, which we're sometimes able to eliminate completely. We also have reduced our number of suppliers because we've reduced parts. By reducing the supplier base for the right reasons, we are able to develop strong partnerships that drive trust and allow suppliers to be open and constructive during the early design stages.

See Also