Are You Improving Quality, Or Just Managing the Status Quo?

Many IndustryWeek readers will be familiar with the use of a quality management system (QMS) to establish quality objectives. But as the name implies, a QMS is more about managing quality than improving it. Raising quality to a new level requires a strategy that sets a clear vision for where you want to be.

Much more than a methodology, a quality strategy should not be limited to one specific area, such as manufacturing, but rather encompass a company-wide vision. It requires a higher level of thinking, with the intent to raise the level of maturity across your entire business—for example, thinking about preventing problems and not just finding them.

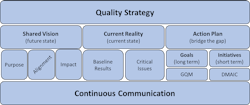

The diagram below provides a framework for developing a quality strategy. This framework breaks the strategy into three key parts: shared vision, current reality and action plan.

Shared Vision (Future State)

From a quality perspective, your vision should paint an inspiring picture of your future state. It needs to be defined clearly, in measurable terms. If you cannot clearly define it, how will you know if you get there? That is not to say that things cannot change along the way (and they most likely will), in which you will have to adjust. But the more specific you are, the better you can put a plan in place to get you there.

When we talk about vision for quality, it is to support, not replace, the company vision. The important point is developing a quality strategy that stretches the organization to a new level. With respect to quality, where do you want to be in one year? three years? five years?

Your shared vision should generate excitement and passion. It should inspire action and propel you into improving your customer’s experience, your employee’s experience, and your overall business success.

Current Reality (Current State)

Before you get to where you want to be, you must know where you are starting from. You need to establish a baseline to understand how steep the climb will be toward your future state.

Ask these questions:

- Where are you today?

- What’s working?

- What’s not working?

- Why is it not working?

- What measurements are in place?

- What can be measured, that is not?

- How do you expect your customers’ needs to change over the next 3-5 years?

To fully understand your current state, you may need to reflect even further. Is the data you are currently collecting being used effectively? If not, why not? What obstacles or challenges can impact you? How do you handle issues when they happen? Do different groups or functions handle issues the same way? Are there best practices that can be shared?

Action Plan (Bridge the Gap)

You can build a plan once you know your current state and where you want to be. The “distance” between these two points is the gap you need to bridge to succeed. The details of your action plan get worked out through goals, milestones and metrics that become your roadmap.

To start, ask yourself the following questions:

- What actions and decisions caused your current position?

- What could be done differently?

- What critical issues you are dealing with today?

- What critical issues do you expect in the foreseeable future?

- What changes/improvements can you make incrementally to reach your desired state?

Goals and Initiatives

Effective goals and initiatives will drive your action plan. You will have to consider all factors contributing to the overall effort (e.g. resources, budget, training, workloads, constraints, etc.). Achieving a lofty vision does not happen overnight. The action plan will consist of some long-range goals with short-term initiatives to achieve them.

For developing goals, SMART (Specific, Achievable, Relevant, and Time-based) is a helpful and commonly used approach. But when working on a more strategic level, I would strongly suggest the GQM methodology. GQM (Goal-Questions-Metrics) is a methodology by two NASA scientists that was originally developed for software analysis, but provides a great framework for developing any goals associated with products, processes and people.

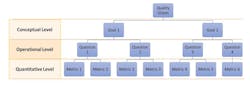

This is a top-down method, shown in the diagram below. It starts by creating a meaningful set of goals for your organization. You then develop the questions you want answered to help achieve those goals. Lastly, you define metrics that will help you answer those questions.

As you flush out the information about your goals, questions, and metrics, everything should tie back to your vision in the form of a tree structure. Goals tie back to vision, questions to goals and metrics to help answer questions.

Conceptual Level: At the conceptual level, you define the top goals that feed your vision. Based on your desired future state, determine the top 3-5 goals that will help you achieve it. Clearly defined goals will add clarity to your overall vision. Based on these goals, setting short-term projects/initiatives will provide the critical steps to achieve long-term goals.

Operational Level: At the operational level, determine what questions must be answered to achieve your goals. These questions will create clarity around assignments, challenges and conditions and help determine what, where, when and by whom things are done. They also expose potential relationships between goals and initiatives.

Quantitative Level: At the quantitative level, we determine which metrics will help us answer our questions. Describe a quantifiable value that helps create a shared understanding of what is being measured. Develop a set of metrics associated with every question in order to answer it in a measurable way. Some metrics may support more than one question.

GQM Example

Here is an example of GQM for a manufacturing operation.

Goal: Reduce the defect rate in manufacturing

Question 1: What is the overall defect rate across all products?

Question 2: What are the manufacturing yields at final test by product?

Question 3: What is the average defect per unit by product types?

Question 4: What is the rolled throughput yield across all stations?

Metric 1: First Pass Yield by Product

Metric 2: First Pass Yield by Station (per product)

Metric 3: Rolled Throughput Yield (all stations)

Metric 4: Defect per Unit by Product

Metric 5: Top Process Issues for Last 12 Months

Final Thoughts

To grow buy-in and engagement, consistent communication across the organization is key. Employees need to know the “what” and the “why” of your strategy. Successful implementation will depend heavily on your ability to share, educate, ask for feedback and be willing to refine your message.

A great quality strategy should have a positive influence on your culture by feeding into the social esteem and self-actualization needs of employees. Having a clearly stated direction is empowering. It creates purpose. Team interactions, day-to-day decision-making and productivity should improve with a well-communicated strategy and vision that people buy into. Then you can continue to build on your vision by selecting the tools and methods that best fit your specific goals and objectives.

Joseph Diele is owner and principal consultant of Diele Consulting LLC and the author of Sustainable Quality.

About the Author

Joseph Diele

Owner and Principal, Diele Consulting LLC

Joseph Diele has more than 30 years of experience in large technology corporations and small technology startups. He is author of Sustainable Quality (Business Expert Press) and an influential leader with extensive background in the business disciplines of quality improvement, operations and change management. Joe’s proven strengths include analysis, problem-solving and change management.

Known for driving positive change and improving business performance, Joe has been on the cutting edge of new methods and practices and has consistently raised the level of maturity in the organizations where he has worked or consulted for. Throughout his career, Joe has been well-recognized for leading transformative change and building high-performing teams. His interests include developing creative solutions for systemic problems, continuous improvement and examining culture as it pertains to quality and operational performance.

At both large and small companies over 30 years, he mentored, coached, and helped develop many new and struggling managers. Joe developed the Sustainable Quality Model for Executives, helping to guide them and their organizations to new levels of performance.

He is a Certified Lean Six Sigma Black Belt (LSSBB), Certified Executive Coach and Mentor (CECM) and a trainer for American Society of Quality (ASQ).