Seventy-five years ago, Stuart Hanan, a young chemical engineer from Brooklyn, was asked by a friend what he knew about whipped toppings. “What’s a whipped topping?” Stuart replied. It was the 1940s, so the fluffy concoction wasn’t a thing yet.

“Could you look into it?” the friend inquired. Stuart did, and soon he and the friend were partnering on a whipped toppings venture. Four months later, the friend dropped out and Stuart kept going with the business, hand-delivering his product to customers in canisters small enough to carry on the Brooklyn subway. It was the right time: post World War II, heavy cream was in short supply, so bakers needed a replacement.

The company, Hanan Products, soon moved its operations to Long Island and endures today. It is now run by Stuart’s son Frank (CEO) and his grandsons, Paul (CFO) and Ryan (COO). The manufacturer and wholesaler of premium whipped toppings, icings and fillings has doubled in volume since 2000, thanks to supermarket business growth and new business in the southern U.S., Central and South America, and the Middle East. It has introduced a natural products line, received vegan certification for some products and embraced technology in its operations-including a digitized inventory system and a customer-facing virtual technician interface, both important during COVID. And, all the while, Hanan has maintained a thriving kosher products business that goes full tilt in the weeks before Passover.

Frank, Ryan and Paul Hanan talked with IndustryWeek about keeping a small family business (26 employees) dynamic, relevant and thriving as food manufacturing becomes digitally transformed.

You all grew up in the company. Frank, were you helping out when you were a teenager?

Frank: I started at Hanan Products when I was 14. I had the glorious job of washing everything: from cans to machinery to floors. I enjoyed it.

Ryan: Paul and I had that same job at that same age. I definitely remember those summers, waking up early, going into the plant, packing the buckets and pallets.

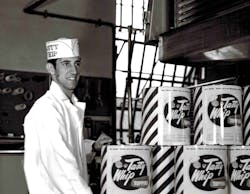

Paul:I have even earlier memories. My dad would come and check on the plant, and he would whip up a little bit of product for me. And I remember being like, 7, 8 years old eating out of a cup. That was cool.Stuart Hanan sold his Tasty Whip topping for 15 cents a pound.

Frank: They always knew what was going on at the business. But it wasn't until they decided to delve in with both feet where the real learning process began. It’s a complicated business. There's a lot of systems, and it can be a difficult learning curve.

Ryan: I studied business at the University of Vermont. You’ll learn how to run a business on paper, but that literally means nothing until you get into a real business environment.

Frank: Business is generally business, they all function the same way. But there's no master's degree in whipped topping. We’re SQF (Safe Quality Food) certified. We have multiple kosher certifications. But the manufacturing is unique and specific to our company because my father and grandfather both came from science backgrounds. The backbone of this company was built through technology and food science, in research and development of our products. Many of those products that were created by my grandfather and my father, we’re still selling today.

Talk about how your products have evolved.

Ryan: We classify our products into three categories. The bulk—which we've made 40, 50, 60 years—are ready-to-whip toppings. They come frozen and everything is wholesale, so the baker is going to thaw them out, put them in their mixing machines, whip them up for 10 or 15 minutes, and you get a big, bold whipped topping. We make a lot of those—dairy, nondairy, and tons of different varieties, flavors, colors. The second category, pre-whipped toppings, is fairly recently developed. They come in a big bucket. The bakers scoop it out, put it on the cakes, and it’s really catered for convenience. A lot of in-store supermarket bakeries use those. It helps them save on labor costs. There are not a lot of technical aspects that go into it, so we felt that we hit a real need in the market by creating those products. And the third category is our premium, all-natural whipped toppings, which we have very little competition for; it's a new market. Like all aspects of the food industry, we see the trend moving to all-natural products.

What are the challenges with developing the natural products? Why is there no competition?

Ryan: I wouldn't say it's easy to make [standard] whipped toppings, but there are a few competitors. You can do it with chemicals, stabilizers, artificial emulsifiers, artificial flavors, high-fructose corn syrup. We’re trying to move away from those ingredients. It takes a lot of research and development. We’re really happy with where we are at this point. We started looking at it maybe two years ago, and have rolled out a few products this year in that all-natural segment. We’re finally feeling comfortable putting our name on a product that has nice stability and holds up to the high-quality products that we like to represent.

Did you invest in equipment for the newer product lines?

Ryan: We brought in a lot of new equipment for the pre-whipped products. The all-natural products required duplicates of the machines we already had—which is nice, they conform to our existing systems. We do need a lot of different storage capabilities for those natural ingredients.

Frank: Whipped toppings have to be delicious, of course but they also have to be extremely functional. They have to freeze and thaw multiple times. They have to be able to whip up to a particular volume; they have to have a specific gravity, pH. It’s a complicated emusional problem because so many factors must be questioned. Simple things like, if somebody takes a gallon of our product and puts it in a mixing bowl, how long does it take to whip up? If it takes 35 minutes, they won’t want to use it. It can literally take years to develop the type of products that meet all the factors we're interested in.

Do you have in-house R&D or do you work with an outside partner?

Frank: My father was the first R&D director. I was the second, for over 20 years. Now we have a full-staff R&D [four people]. But almost as importantly, is that absolutely everything that we do is in-house. We don't buy formulas. We don't buy premixes, we don't ask people for information. Everything that we have ever done has been done completely in-house so that we have complete control.

What are you hearing from your customers about what they want?

Ryan: We speak to our customers on a daily basis. The customers are the ones pushing us forward towards these all-natural products with a more, say, Whole Foods sensibility.

Frank: We also have an extensive kosher Passover line. We’re a manufacturer for some of the largest kosher establishments in the United States. Very well-known retail distributors, and we private label under them. We've been doing those products now for probably 40 years. It’s a nice piece of our business. We basically run for almost one solid month nothing but kosher-for-Passover product, and that extends through the year for other rabbinical groups.

What’s involved in switching over to kosher production?

Ryan: It’s hectic. Basically, we need to build inventory. This year, we're looking at about three weeks of no regular production. So in the final months of the year, we're building up our inventory levels on our regular items. And then we essentially shut down the facility and produce like crazy all these kosher-for-Passover items in short amount of time. The rabbis are here, they have to kosherize the system, they're on call. They're in the facility watching everything that we do—making sure that certain temperatures are hit, that everything is pasteurized and cleaned to their liking. We’ve been doing it for so long, we know what to expect. Our workers are almost friendly with the rabbis at this point.

Are the rabbis around all the time? Or do they just pop in once in a while?

Ryan: During normal production throughout the year, they'll pop whenever they want, a few of them. For kosher for Passover, they're here full-time.

How did you build that customer base?

Frank: We built it one customer at a time, based on quality products and reputation. If there's a problem, we're there to address it. If there are questions about the product, about how to use it, we're there for them. If somebody asks us for a product sample, we don’t send it to them. We take it to them and help them with that sample, so that they can learn all of the aspects of it—the functionality and the attributes. Too many times you throw out a sample to somebody, they don’t understand it. We want to make sure that they understand where the product’s coming from and what it can do for them and what our relationship is going to be like long-term.

You’re modernizing some of your operations, introducing some automation around repetitive tasks. What’s the plan?

Paul: We implemented Sage Inventory Advisor. In the past, we had to look at inventory levels, we would look at our MRP, which is not cloud-based. You physically had to be in the building, or physically look at the inventory, and get counts and see what production looked like. A lot went into ordering raw materials or planning out finished-goods production. Now, this software uses artificial intelligence to bring all that into one place, and it forecasts for everything that we would buy or make. It is cloud-based, so people can do that at home if needed. And it gives the business a lot better insight into what we need, what we have to make, as opposed to scrambling and doing guesswork and sometimes being caught off guard with things.

Did you have any challenges around integrating the system?

Paul: It’s a complicated system. Usually, I’ll get trained first and train people based on what they know. But with this system, they have a pretty good in-house training system. They do monthly webinars. So I've tried to get people up and running with those. Implementation was not bad. Getting people comfortable using the system has been the harder part.

What were your challenges around COVID?

Frank: We've been through serious recessions. Breakdowns and storms and hurricanes have shut us down. Nothing has come close to this. And that’s a tribute to every employee that works here, that everybody cooperated. We were down for almost two solid months, and in the first two days of the shutdown we had $500,000 worth of orders cancelled. And of course, our international business seized up completely. It was horrific.

A lot of our success during COVID has to do with the way that Paul instituted his software programs and made it available for us to work at home. Logistically, we had a skeleton crew working here a few days a week. We converted some of our inventory so that we could immediately sell it as soon as things freed up. And we had people here when they were needed, and people at home when it was safer. And the system worked nearly flawlessly. Particularly the way that we integrated Slack into Salesforce. Everything was very streamlined. You had your inventory advisor in there, so everything was in one spot. Salespeople, production, office people knew it.

What's your vision for the company? What do you see happening in the next five years?

Ryan: The key for us is managing those relationships with our customers, understanding the needs of the market, and then continuing to provide them with high-quality products. And then continuing to combine new technology advancements, innovation and robotics in order to achieve those goals. That's the five-year plan.

Frank, do you have any advice for other smaller manufacturers as far as succession planning?

Frank: We felt that we had to offer this to our children if they wanted it because I truly believe it's a great legacy. If you have faith in your business and in your kids, then it's a good thing to deal with. Going into third generation is very difficult, okay? In order to get to the third generation, you have to start strongly with the first generation. You have to build something that's worth continuing. My motto, when it comes to business, is you have to stay focused. It can never become a secondary sport, or a hobby, or “I'll take care of it next week.” You have to stay focused, you have to have good people, and you have to have to live by your own set of values. I don't think there's a company out there that’s going be here in five more years, if they don't have high-quality products. And that's what we’re focused on. Quality, quality, quality and customer relationships.

Main photo, from left: Ryan, Frank and Paul Hanan, surrounded by cakes (decorated with Hanan Products toppings, of course) at the company's 75th anniversary celebration.

Got a manufacturing C-Suite candidate for Profiles in Leadership? Contact IndustryWeek Senior Editor Laura Putre.

About the Author

Laura Putre

Senior Editor, IndustryWeek

As senior editor, Laura Putre works with IndustryWeek's editorial contributors and reports on leadership and the automotive industry as they relate to manufacturing. She joined IndustryWeek in 2015 as a staff writer covering workforce issues.

Prior to IndustryWeek, Laura reported on the healthcare industry and covered local news. She was the editor of the Chicago Journal and a staff writer for Cleveland Scene. Her national bylines include The Guardian, Slate, Pacific-Standard and The Root.

Laura was a National Press Foundation fellow in 2022.

Got a story idea? Reach out to Laura at [email protected]