In 2005, 20 children died while playing with toys. Nine deaths were due to choking on the toys, which included six balls, a balloon, a bead from a toy-horse figurine and a toy dart, according to an Oct. 5, 2006, memo from the United States Consumer Product Safety Commission (CPSC).

Also in 2005 there were an estimated 202,300 toy-related injuries treated in U.S. hospital emergency rooms, reports the CPSC, which has jurisdiction over about 15,000 types of consumer products -- from automatic-drip coffee makers to toys to lawn mowers.

For the Bethesda, Md.-based CPSC, an independent federal regulatory agency created in 1972 by Congress in the Consumer Product Safety Act, these horrible stories are meant to elicit action: action from manufacturers, and more importantly -- action from consumers.

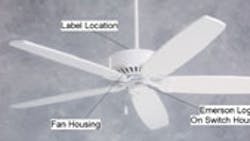

Indeed, from September 2006 to December 2006 the CPSC announced numerous recalls for products because of potential fire and burn, personal injury, choking, lead and carbon monoxide poisoning, and laceration hazards. Recalled products include Black & Decker U.S. Inc. blowers and vacuums (fire hazard), Emerson Electric Co. ceiling fans (falling blades), Square D Co. safety switches (shock and electrocution hazard) and GAMO USA Corp. air rifles, which unexpectedly fire.

For example, Square D announced a recall for 27,600 of its General Duty Safety Switches. According to the company, the safety switch can continue to supply electricity even after being placed in the "OFF" position. At the time of the recall announcement no incidents or injuries were reported. The recall notice also details where the product was sold, shows catalog numbers of the units and offers a remedy to consumers. In this case, consumers were asked to return the uninstalled safety switches to the retailer or distributor where purchased for a free replacement unit. Installed safety switches were replaced free of charge by contacting the firm.

So why would a company voluntarily recall its products if no serious injuries occurred?

Mock Recalls

Another way manufacturers can make consumers feel confident about products is to take part in mock recalls.

For the food and consumer packaged goods industries, which are governed by the Food and Drug Administration (FDA) and the U.S. Department of Agriculture (USDA), mock recalls are pretty much a requirement.

"The FDA put the Bioterrorism Act into effect about a year ago," says Scot McLeod, senior vice president of CDC Software, a global ERP solution provider. "The Bioterrorism Act mandates that food processors have to be able to conduct traceability in support of things like recalls, and if they can't and there is an incident, there can be severe penalties imposed."

In 2002 the FDA mandated 5,000 recalls and made 286 arrests, according to McLeod.

"Manufacturers aren't concerned so much about the penalties that come from the FDA, but the brand damage that can occur," explains McLeod. "The driver behind mock recalls is brand assurance, or brand protection. The retailers are putting the pressure on the food processors to constantly prove and demonstrate that they are taking the steps necessary to protect their brand image."

In fact, McLeod was talking with an executive from Wal-Mart who said if price, quality and customer service are equal among suppliers, then brand assurance can become a tie-breaker.

"When I first got here, the mock recalls were taking about 12 to 20 hours," says Gary Gold, corporate vice president of quality systems at Berner. "In the first year we got it down to six hours. We kept fine-tuning it. We laid out the flow and found some problems and we took that information from the floor and started entering it sooner into the system. When we did, we went down to 23 minutes."

For Gold, quality control is paramount because he says in the food industry, "Each minute that passes by, tens or hundreds or even thousands of lives are in danger."

Prior to joining Berner Foods, Gold worked in the aerospace industry for 15 years and the automotive industry for eight years.

"Even though food and aerospace are different, security is very important for both," notes Gold. "I have been doing safety with Berner for three-and-a-half years -- meeting and exceeding the FDA, USDA and bioterrorism needs."

Berner Foods uses CDC Software's Ross ERP solution to track and trace. The solution allows Berner to trace everything that goes into a product and where the product ends up.

"We have an interlocking process in place for each step of our production," Gold says. "As we go through, we are able to document, record and file all the lot numbers. Our operators sign off, so we know what day, what time and how much. That's [the information] you've got to know."

On a typical day, Berner could have 40 different product labels going on the line at the same time. With 4,000-pound batch sizes, there is a lot at stake.

| The Office of Compliance at the U.S. Consumer Product Safety Commission has prepared the following recall checklist to help manufacturers conduct an effective and comprehensive product safety recall: Production

Source: The Office of Compliance at the U.S. Consumer Product Safety Commission |

Dormant Technology

Who uses every function on their PDA? Consumers pay for all the bells and whistles, but rarely do they utilize each feature. The same goes for tracking and tracing technology.

"Many companies, although they have the technology available to them, still tend to track and trace in a manual environment," says Connie Green, ERP product director for PEAK Technologies, a Columbia, Md.-based provider of automated identification and data collection systems. "They tend to manually write down the products that went out the door, instead of using data capture of any type -- even bar codes."

According to Green, if the threat of a recall hasn't occurred, folks get lax.

"They are all betting like they are in Vegas," says Green. "They are betting on what's the chance of this recall happening. Then if the recall happens, they have to dig into all their paperwork. It is a very time-consuming and costly process."

If manufacturers are doing any type of data capture, then they have the capability to capture data relevant for recalls, Green says.

"They already data capture internally," he explains. "You go to any manufacturing plant and they know what components went into the finished good -- it just seems to stop there. They need to track that finished good on the outbound documents to that end user."

As an example, Green relays a story of a PEAK customer who went through a major medical recall. It took the company 300-plus hours to find where all the recalled product went.

"They had automation, but they just weren't using it," says Green. "Then they started using it to track outbound deliveries of what went to whom."

When the company redid the recall in a mock environment, it only took them about 13 minutes.

"Companies need to be proactive before it happens to them," stresses Green. "The tire industry I am sure can give great speeches to that. How hard was it for them to find where all their tires went? It was horrible. But today they can probably tell you where 90% of every single end-user item is. They put in the technology to do it."

In fact, for consumer products the effectiveness of a recall is only about 30% to 40%. With more than 400 product recalls in 2005 representing 67 million units, that's only 20 million to 27 million recalled units making their way back to manufacturers, Dampier says.

The reasons: the price of the item, the remedy that's chosen by the manufacturer (i.e., how simple it is) and the potential of danger.

"We were involved in the laptop battery recall, so the potential that it could catch your lap on fire made it an effective recall," notes Dampier.

Another reason the recall was effective: "Dell and Apple were very proactive while it was a voluntary recall," says Dampier. "[Early on] they launched some very nice recall programs and several weeks later it became a mandatory recall. The companies that get out front and are more proactive and have fast response have better success."

Newgistics notes that the onus is on the consumer to take the action during a recall.

"We know from our research with Harris Interactive that consumers want simplicity," says Dampier. "We asked, 'If you had to return merchandise for a recall, how would you prefer to return it?' Three out of four consumers said they would prefer to return it from home via the postal service -- hand it to the postal carrier. They also wanted it to be a prepaid method."

Newgistics offers its SmartLabel solution -- a peel-and-stick prepaid label that manufacturers can provide to consumers in the event of a product recall. The label is placed on a package and then handed to the mail carrier.

There are a number of challenges when a recall is put into place, according to Dampier. Manufacturers have to react quickly and figure out how they are going to communicate with consumers and retailers.

"Sony had to recall 9.6 million laptop batteries. There's always a potential for damage to your brand, so you have to go into damage-control mode. That's a lot for a manufacturer to take on at a moment's notice."