2024 IndustryWeek Best Plants: Two-Way Accountability Drives Excellence at Hoffer Plastics

Most manufacturing is high volume-low mix, such as automotive parts where companies crank out millions of the same thing constantly, or low volume-high mix, such as machine shops that make a few copies of a part before moving on to the next job.

Hoffer Plastics

- Location: South Elgin, Illinois

- Products: Injected-molded plastic parts such as bottle lids and medical components for a variety of customers and proprietary plastic products it developed internally

- Employees: 359

- Plant operations started: 1953

Hoffer Plastics in South Elgin, Illinois, about 40 miles west of Chicago, is the much rarer high volume-high mix producer. On one day in August, injection molding machines were rapidly cranking out lids for pill bottles, plastic components for restaurant soda fountains, automotive parts, lids for apple sauce pouches, corkscrew-style wall anchors for home DIY construction projects, lawnmower components and the tops of flavored coffee creamer bottles.

Its ability to juggle complex production, hit exacting on-time delivery targets, support employee development and embrace high-tech solutions (where they make sense) all led our judging panel to name Hoffer Plastics one of two 2024 IndustryWeek Best Plants Awards winners.

As with most winners throughout the years, Hoffer Plastics doesn’t get one or two important things right. Its dedication to operational excellence flows from core principles and a highly intentional approach to most decisions. “Intentional” is a word that pops up a lot when talking to Hoffer people – more on that later.

Back to its product diversity. William Hoffer, chairman of the company and son of founder Robert Hoffer, says many plastic injection molding companies pick one industry, such as automotive, and schedule all production on a narrow set of products for a few key customers.

“We’re anything but that,” William Hoffer says. “We are at the most 60% packaging, and then a lot of consumer industrial and then a smaller portion in automotive.”

Driving that ability to service lots of customers in radically different industries is a set of core relationships, internal and external to Hoffer.

On-Time Delivery

IndustryWeek Best Plants Award judges gain access to in-depth, proprietary data on facilities being considered for the program, looking at everything from profitability to safety to inventory management. With Hoffer Plastics, one statistic that stood out was 99.4% on-time delivery rating for 2023 – based on the dates that customers requested material, not when Hoffer promised to deliver it.

“We have some really strong relationships with people in the resin market. We've built that trust with partners,” Alex Hoffer says.

Co-CEO Gretchen Hoffer Farb adds, “We didn't shut anyone down during the largest supply chain crisis in our markets’ history, because of relationships and because the team came together and troubleshooted around it. It all comes down to transparency and communication. We worked with the customers, telling them that we needed accurate dates.”

With achievable delivery target dates, she adds, Hoffer’s team was able to negotiate with suppliers and employees to reach those. None of that would have worked without those key relationships internally at Hoffer and between the company, its suppliers and its customers.

William Hoffer adds that on-time delivery is one of those old-school metrics that has always been important.

“That’s one of those things that was not only a requirement, it was a necessity,” for much of the company’s history, he says. “So, I think we maintained that mentality: ‘Why can't we? Let's make it happen.’”

Internal Transparency

On-time delivery wasn’t the only area where Hoffer Plastics stood out. Simple methods to engage with employees show a dedication to the core lean principle of showing respect for people.

An example: During the visit in August, some carpeting in the office had bunched up in an area, creating a minor tripping hazard. Simple paper signs with a familiar cross-pattern explained what was going on to employees. In the top-left quadrant was an explanation of what was happening—carpeting was being replaced. In the lower-left, an explanation of why—the tripping hazard. On the upper-right, when the work was being done—the following weekend. On the lower-left, who would be affected by the work—the departments working in and around the space where the carpet needed replacing.

Similar signs were all over the plant, telling employee why and when aging equipment would be replaced or when new lanes would be painted on the shop floor. Jeff Klabunde, plant manager and vice president of operations, says the four-quadrant signs are simple, cheap, easy to digest and show employees exactly what’s going on around the facility in detail.

“People always want to know what’s going on and why, and if you don’t tell them, they’re going to imagine what they think is going on,” Klabunde says. Showing the why, when and who for each change in the plant, no matter how minor, Hoffer Plastics avoids needless speculation.

The signs also provide accountability for the company to its employees. If the sheet says a potential safety hazard will be fixed by Saturday, employees expect something to be different when they come in to work on Monday.

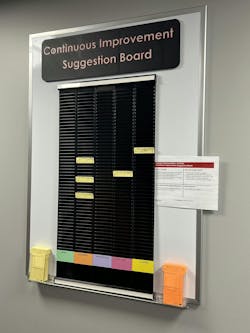

Another form of accountability comes from how Hoffer collects continuous improvement suggestions from employees. Like most modern manufacturers, Hoffer Plastics’ employees clock into work electronically, but the company still has four giant racks around the plant used to store paper employee time cards. Those racks now serve as a visual tracking system for how quickly management responds to employee concerns.

More on Hoffer Plastics

Plastics Machinery and Manufacturing, a publishing brand owned by IndustryWeek parent company Endeavor Business Media, has written about Hoffer Plastics several times.

Within a few days, management must read the suggestion and assign it to a leader to consider and study the problem/solution. At that point, the card moves one slot to the right, showing everyone that the suggestion has been read and assigned. Anyone can pull the card out of the slot and see who’s now in charge of considering the change and when they should have a decision made.

When the manager finishes studying the problem, they will respond on the card and move it another slot to the right. If Hoffer Plastics decides to make a change based on the suggestion, the card moves another slot to the right. So, at a simple glance, employees can see how many change recommendations they and their peers are making, how far along the process those suggestions are and what impact those suggestions are having on operations.

“We’re showing people every day that we value their input, and that it’s not a suggestion box. We’re holding ourselves accountable to considering every suggestion and showing progress,” Klabunde says.

Vision Systems, Cobots, AGVs, Oh My!

While creating simple, direct signs in Microsoft Word and hitting print or using old timesheet racks are examples of inexpensive, low-tech approaches to operational excellence, Hoffer Plastics has embraced high-tech, advanced manufacturing as well.

The company maintains a robust capital expenditure program to replace aging injection molding machines, standardize equipment for toolmakers and improve material handling. Nearly every injection molding machine has a camera-based inspection system attached, taking pictures of every part to check its accuracy to geometric tolerances. Robotic systems move material between machines and handle most physical tasks.

Klabunde says the technology allows the plant’s workforce to spend more time on inspection, machine tending and similar tasks. On one product line handling parts that Hoffer Plastics’ engineers developed internally, collaborative robots handle much of the packing operations, and autonomous guided vehicles deliver empty boxes to the line and take away the filled ones.

Adam VanMeter programmed much of the complex system, despite not having been a warehouse employee and shift supervisor working the late shift until two years ago. During the pandemic, VanMeter spent much of his downtime watching YouTube videos about cobots and automation and started talking to his supervisors about the potential for such systems at Hoffer. Some training followed, and Hoffer promoted him to automation project manager.

“One of the things that I learned that I brought to the company was that automation was getting easier. It wasn’t about programming G-codes anymore; it was about moving the robot arms around and teaching them what to do,” VanMeter says.

Klabunde adds that supervisors were aware of VanMeter’s interests and able tap into his growing expertise because of how Hoffer Plastics structures its operations.

Plants Within Plants

All of Hoffer’s operations in Illinois are under one roof, but management and employees talk about nine different plants. Each of the facility’s large manufacturing spaces considers itself to be a separate plant with its own managers and supervisors. Each of those sub-plants focuses on specific product lines.

Changing Colors

Orange, blue, red, green, white – color is very important at Hoffer Plastics.

The next time you’re in the grocery store, take a look at the lids on those bottles of flavored coffee creamers. Odds are, they came out of South Elgin, Illinois. Employees can tell the time of the year by the colors of those lids. Late August through much of September is a sea of orange as pumpkin spice season hits. Shortly after, the greens and reds pop up for Christmas peppermint flavors.

Then, there’s the loyalty colors. For competitive reasons, the folks at Hoffer didn’t want to share the identity of one of its oldest, core customers, but developing plastic fittings for fast-food restaurant soda machines led to a multigenerational contract with one of the largest and oldest soft drink brands in the world. Key signs throughout the sprawling plant, and the chairman’s car, all feature a primary color associated with that brand, and I’ll leave it to you to decide if that means red or blue.

Yet, the facility benefits from economies of size by sharing tooling employees, having an electricity co-generation plant that would be too expensive for a small operation and having better access to large suppliers and top-tier logistics delivery services.

Jack Shedd, executive vice president, says Hoffer Plastics gets scale, customer diversity and product specialization from its decision to have each space operate somewhat independently.

“It really drives not only product intimacy by our employees, but also customer intimacy,” Shedd says. “[Employees] know the customer very well. They’re all in for that customer to make sure that they're getting their delivery. … What we do really isn't different than any other injection molder. The way we compete is through outstanding customer experience with on-time delivery, perfect quality. The focus-factory concept drives that.”

Klabunde adds that having plant managers and supervisors working with smaller subsets of employees keeps management tied into the needs, concerns and great ideas of employees.

Continuous Improvement

You can point to the low and falling scrap levels, improved quality metrics, on-time delivery and other KPIs as reasons why Hoffer Plastics deserves to be considered one of the best plants in North America. But the lack of complacency is probably its biggest asset.

The timecard suggestion boards, for example, are new, only implemented this year. Klabunde says that before implementing them, managers had collected ideas from employees but had no tracking system to ensure accountability for really considering ideas. And, like many great ideas in manufacturing, Klabunde stole it from a competitor… or maybe “traded” is a better term. Klabunde saw the boards at another plant during a tour and loved them, and that plant’s manager loved his four-quadrant sign system.

Alex Hoffer says continuous improvement and 5S strategies have been core to the company’s approach for decades and stretch from operations to personnel to sales.

“One of the things that we identified is our customers are constantly looking at launching projects in a more efficient manner, so [Director of Engineering] Brian [Beringer] is taking it up in leadership,” Alex Hoffer says. “We have a team working on a product launch system to expedite product launches. So, feedback is something that we’re always interested in, and we’re always documenting.”

Meet the Chief and the Chief and the Chief

About 10 years ago, William Hoffer began thinking about retirement and succession planning. And, as the second generation to run Hoffer Plastics, he looked to his own children as potential replacements. But, which of the three could take over? Charlotte Canning, who was interested in marketing and human resources? Alex Hoffer, who had worked as a teacher for a few years but was then interested more in operations? Or Gretchen Hoffer Farb, the CPA?

Instead of choosing, the company now has three co-CEOs. Functionally, it’s similar to European boards of management where each leader has an area of expertise and authority, but they come together to find consensus on bigger issues that cross those boundaries.

It’s an unusual arrangement, but the siblings say it’s worked well for them and the company for the past several years. They became co-CEOs just in time for the pandemic to hit in 2020.

“Throughout the company, our people know exactly who to go to and how to get things done,” Charlotte Canning says. She adds that she, her brother and her sister stay in their lanes at most times, and when there’s a conflict or decision that crosses those boundaries, it’s easy to have a quick meeting. Most of those take less than five minutes.

Alex Hoffer says, “We're further along in our relationships as siblings – forget the business – than we would have been otherwise,” adding that other families tend to avoid painful subjects or big differences of opinion to avoid conflict. “We're running company together. We can't afford that. We have deep conversations, and we have a really good relationship because of It. We've also been very intentional about it.”

Gretchen Hoffer Farb again mentions the family’s intentional approach to power sharing, saying that the three siblings work with an executive coach to navigate the relationship. Think of it as a mix of family counseling, corporate strategy and operational efficiency consulting.

The first step – getting every sibling rivalry or annoyance on the table. Your sister got the big piece of cake at your 7th birthday? Let’s talk about it and move past it.

“There are things that we worked through early on. We had to be very intentional on putting everything behind us,” Canning says.

About the Author

Robert Schoenberger

Editor-in-Chief

LinkedIn: linkedin.com/in/robert-schoenberger-4326b810

Bio: Robert Schoenberger has been writing about manufacturing technology in one form or another since the late 1990s. He began his career in newspapers in South Texas and has worked for The Clarion-Ledger in Jackson, Mississippi; The Courier-Journal in Louisville, Kentucky; and The Plain Dealer in Cleveland where he spent more than six years as the automotive reporter. In 2014, he launched Today's Motor Vehicles (now EV Manufacturing & Design), a magazine focusing on design and manufacturing topics within the automotive and commercial truck worlds. He joined IndustryWeek in late 2021.