Intelligent Enterprise is Key to Manufacturing Turnaround

In their Harvard Business Review article “Restoring American Competitiveness,” Harvard Business School professors Willy Shih and Gary Pisano argued that restoring the ability of enterprises to develop and manufacture high-tech products in America will be important in restoring our country’s competitiveness. However, in a recent interview professor Shih graded the nation’s effort to drive a manufacturing renaissance a “C-.” So how can we move the needle? By leveraging advances in connectivity and computing, we can drive new levels of data-driven insights—something we call the “intelligent enterprise.”

Technology and innovation both play a critical role in creating a vibrant U.S. manufacturing environment, resulting in better products and more efficient processes. The industry appears to agree. A recent study found that 66% of warehouses plan to expand technology investments by 2018. Today, a technology transformation is underway driven by the convergence of ubiquitous mobile connectivity, computing on demand via the cloud and the recent emergence of entirely new classes of connected things. The number of Internet-connected “things” today is about 14 billion, and we’ll see that go north of 50 billion over the next five years.

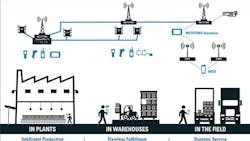

For manufacturers, it is all about improving productivity on the plant floor with technology that reduces task time and physical strain, while fulfilling customer demand effectively and at an acceptable cost. But in order for this transformation to reach its full potential, manufacturers need to also focus on improving their production capability in addition to enhancing their warehousing and logistics operations. The more connected they are, the more effective they will become.

Manufacturing facilities and their associated supply chains are effectively becoming platforms where workers, buildings, assets, inventory and infrastructures are more connected, more intelligent, and able to provide information across and from the edge in real time. The challenge is to bring all of this disparate information together into an intelligent enterprise platform that allows it to be utilized for making business decisions that drive real-time user experiences and actions. We see the convergence and coordination of fixed intelligent infrastructure with the legacy mobile edge as the next wave that will transform the experiences within the enterprise of the future.

What Does an Intelligent Enterprise Look Like?

Here’s a look at a few of the most compelling benefits that the intelligent enterprise will drive.

Automating Manual Processes

Increasing operational visibility with innovative technology and analytics is a very important part of creating value and driving efficiencies. In this pursuit, the industry vision is to increase the number of barcoded items received at a warehouse or distribution center from 67% today to 84% by 2018. It is also to ensure that supplier and partner processes meet the requirements—and properly utilize the capabilities—of GS1, GDSN, ASN and RFID. This helps support more highly prioritized picking and storage processes and enables stronger collaboration across the supply chain.

But for it all to work as intended, operations and IT leaders must be on the same page with regard to technology systems and business processes. And in most organizations, differences abound. However, bringing both disciplines together with a common vision is one of the most crucial goals over the next five years.

Maximizing Efficiency in Packing, Staging, Loading and Shipping

In the new warehousing world, customer satisfaction is seen as a major corporate objective and differentiator. Fast and accurate customer-driven requirements are playing a more important role in the packing, staging, loading and shipping functions, taking advantage of processes such as load optimization and performance monitoring. A wide variety of technology solutions are poised to help warehouse operations provide outbound material handling to maximize efficiency, reduce costs and enhance customer satisfaction.

Packing stations can be equipped with mobile wireless computers, scanning and RFID devices, and fixed-mount kiosk solutions to increase speed and efficiency while reducing errors and damage. Packages and containers will be marked with intelligent and active tags. Workers will utilize wearable devices to see real-time updates on the next steps in their workflow. These advanced capabilities will help meet aggressive targets. Robust wireless outdoor coverage of RFID and WLAN will integrate dock and yard operations with the warehouse, providing end-to-end efficiency. Integrated video capabilities will be used for quality control and proof of compliance.

Better Visibility Creates New Efficiencies

Today, many manufacturers are asking for holistic solutions to address supply chain challenges. Companies in the logistics sector, for example, are highly sophisticated and very complex, so simply inserting a piece of technology here or there is not nearly as impactful as delivering a solution for an entire supply chain, end-to-end.

One of the challenges customers face in logistics or large-scale transportation of materials is packing efficiency. How do you optimize a trailer load, for example, to improve both worker efficiencies and logistics costs? With advanced analytics, companies now have the ability to accurately assess the state of a trailer, how well workers are loading vehicles and identify errors in real-time to prevent any downstream impact. All this information is immediately available to managers—and in some cases, front-line workers—so decisions and adjustments can be made in real-time. The potential impact on organizations of all sizes and industries? Revolutionary.

Planning for Change

These are exciting times in an exciting space. With the next-generation technologies, a solutions-based architecture will effectively turn the enterprise into a platform used to drive outcomes. Information will be captured in real-time from warehouses, distribution centers, hubs, depots and delivery networks and coordinated with humans who will be connected via traditional devices and emerging wearable systems to enable new levels of operational efficiency.

As technology allows for better quantification of the environment, and the context and location of workers, we will see the adoption of various wearable technologies in the enterprise space enabling a “frictionless” workflow. Workers will waste no time interacting with technology. It will become integrated into their experience and will seamlessly direct and inform them, increasing productivity, reducing errors and streamlining training.

Manufacturers are investing in a wide variety of technologies and solutions to upgrade existing systems throughout their operations—to gain the visibility they need to transform how they work. They must address a number of growing business issues, from changing market dynamics, heightened competition and shorter product lifecycles to a demand for the faster delivery of increasingly customized products. To succeed, they need to find a way to cut costs and increase efficiencies without impacting quality, customer service or product availability. The intelligent enterprise—and the visibility it provides—will be a defining enabler.

Tom Bianculli is senior director of Emerging Business at Motorola Solutions, a provider of mission-critical communication solutions and services for enterprise and government customers. He is responsible for the exploration and development of new business opportunities and product solutions.