Fried Chicken to Firefighters: How Cres Cor Adapted an 80-Year-Old Product Line

Cres Cor is a company that makes hot cabinets, ovens, commercial refrigerators, and utility racks. It’s been family owned since it was founded in 1936 by Clifford Baggott’s father, George “G.T.” Baggott, as a simple sheet metal job shop. But after almost 80 years of the company mainly serving food service industries, the Cleveland, Ohio-based company was hunting for new customers. And who, other than restaurants and caterers, needed hot cabinets?

“As the second generation, you want to leave the business in a different place than you found it — hopefully, better,” said Clifford Baggott, chairman of the company board. “At some point in time in the history of this company, or the future of this company, we have to make other things. And what would those be?”

At that point, much of Cres Cor’s history was based on building hot cabinets with precision controls for heat and humidity. Building on the company’s key capability, leadership put together a team to brainstorm other markets.

Cres-Cor’s Family-Owned History

Crescent Metal Products of Cleveland, Ohio, founded by George T. Baggott initially “just made things people wanted,” says his son Clifford Baggott, chair of the Cres Cor board. After production for WWII-related materiel ended with the war, the G.T.'s company made guards for exposed belts on factory equipment, seatings for fluorescent light fixtures and industrial heating ovens.

The last one became key to what Cres Cor would later become. Hough Bakery in Cleveland centralized its baking soon after the war and brought on the future Cres Cor to reliably deliver fresh-baked products without damaging them. According to Clifford Baggott, the founder took inspiration from the corrugated sides of a tractor trailer to produce heated cabinets with corrugated sides to hold baking trays in place.

From there, the company began selling cabinets to school cafeterias, but the company got its major break when G.T. met an entrepreneur who styled himself as a Southern gentleman. Colonel Sanders’ restaurant in North Corbin, Kentucky, was struggling due to the recent construction of Interstate 75.

Franchising was Sanders' next move, and Cres Cor managed to grow alongside Kentucky Fried Chicken as it franchised across the United States in the 1950s and 60s. After, Cres Cor expanded again into it what became its current business mainstays: School, convention center and prison cafeterias.

“We had a team together that was trying to find other uses for our equipment,” says Greg Baggott —president of Cres Cor, and Clifford’s son. The team looked into what else could be stored in Cres Cor’s specialized metal cabinets with controls for heat, refrigeration, airflow, and humidity.

“Instead of the payload being food, what can the payload be?” Baggott said.

Like many manufacturers, the pandemic proved a useful pivot point. As the country faced a shortage of N95 masks, the company explored an emergency use authorization to use its heating cabinets to decontaminate medical equipment.

“Using heat and humidity, which is exactly what our cabinets do, it decontaminates items to a six-log reduction,” or kills 99.9999% of microorganisms, Greg Baggott says.

Cres Cor’s proposal to decontaminate masks en masse with heat didn’t pan out: Domestic supply chains for the masks caught up before the FDA cleared the cabinets for an emergency use authorization. Taking stock, Cres Cor found itself with an innovative new product in search of a market.

“We said, ‘Ok, we’re on to something, but not with the N95 masks and not necessarily in the medical field,’” said Baggott.

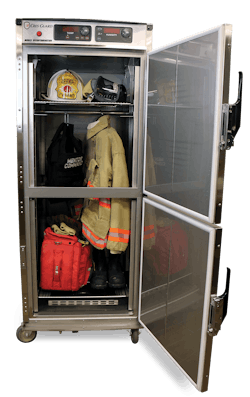

Instead, Cres Cor pivoted to first responders: hospital workers, fire fighters, EMS and police that all find themselves in contact with contaminating biological hazards. Unlike hospitals, many first responders don’t already have systems set up to decontaminate equipment. And as Cres Cor discovered at an industry show, they also have novel needs.

“One of the things we weren’t thinking of was bed bugs,” says Greg Baggott. According to an attendee at the Indianapolis Fire Department Instructors Conference (FDIC), the bugs are a serious concern for firefighters, who are often called on to handle non-fire emergencies that can put them into contact with pathogens and parasites. “They’re picking up these things and taking [them] back to the firehouse, which they’re going to sleep in. It’s going to get on their bedding, it’s going to get in their overnight gear.”

The discovery of a market for Cres Cor’s decontamination cabinets also led to further innovations.

“We went in there learning, using our heat-and-humidity hot cabinet to solve some of those issues, and that was for their hard gear,” Greg Baggott says. “But then we found out that they use a lot of electronics, cell phones, walkie-talkies. That’s not good in a humidified environment. So, we developed a new product as a result of that, that is a similar kind of concept, but it uses heat and UV-C light,” also known as germicidal ultraviolet light.

The timing of Cres Cor’s move into decontamination is fortuitous. Younger first-responder recruits, especially since the pandemic, are reportedly more invested in cleanliness and hygiene than veterans from older workplace cultures.

“The fire stations are involving old guys like me,” says Chairman Baggott, “And they’re like, ‘Oh, dirt is a badge of honor.’ Younger people are like, ‘Hey, I love this job, but I wouldn’t mind, at the end of my career, being safe and healthy.’”

The effort has already landed the company a big client. After seeing Cres Cor at FDIC, Safety Chief of Oklahoma City Fire Department Clint Greenwood “grilled” the company on the cabinets capabilities. He then ordered decontamination cabinets for 45 stations, plus two for the city’s firefighter training center.

“Other than removing clothing and washing, which was easy, it was apparent that certain equipment was difficult to clean, disinfect and decontaminate,” Greenwood says.

Cres Cor isn’t satisfied with catering just to first responders, though. “This is a success in progress,” Clifford Baggott says. The company is looking at selling the cabinets to comparable settings with difficult-to-clean equipment, including sports teams.

“It’s definitely progress, and we have the long-term vision to stick with it,” Clifford said.

About the Author

Ryan Secard

Associate Editor

Ryan Secard joined Endeavor B2B in 2020 as a news editor for IndustryWeek. He currently contributes to IW, American Machinist, Foundry Management & Technology, and Plant Services on breaking manufacturing news, new products, plant openings and closures, and labor issues in manufacturing.