Digital manufacturer Protolabs recently partnered with paralympic athlete ‘Monster’ Mike Schultz to create components for his advanced prosthesis that will enable him to race in the Adaptive Snow BikeCross competition at the upcoming Winter X Games 2020 in Aspen, Colorado.

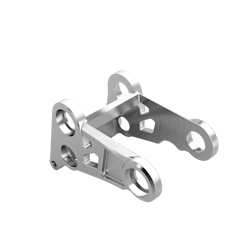

The Moto Knee and Versa Foot2 system are both improvements from previous versions. The goal behind the new versions is to provide Schultz with improved durability as well as a more natural range of motion between his knee and foot. “Anyone involved with elite level competition knows the importance of innovation, progression and adapting to challenges on the fly,” said Schultz.

The backstory

In 2008, the now 38-year-old from St. Cloud, MN suffered a knee injury during a snowmobile competition, resulting in the amputation of his left leg above the knee. The prosthesis Schultz received after his accident didn’t perform as he needed for competitive, rigorous sports. Using his knowledge and experience of fabrication and tuning suspension on race equipment, Schultz set out to create his own durable and versatile mechanical prosthesis.

Schultz is one of eight athletes to compete in Adaptive Snow BikeCross at this year’s X Games, which debuted its first official adaptive motorsport competition—motocross—in 2009 to further support inclusion and progression in athletics. Schultz is a nine-time X Games gold medalist and won a gold and silver medal for Team USA in snowboarding at the PyeongChang 2018 Paralympic Winter Games.

Going digital

Schultz ultimately turned to Protolabs and its digital manufacturing model. Protolabs CMO Brian Peters told IndustryWeek, “The needs of every project are different, and in the case of Mike’s improved prosthesis, the main challenges presented were that it needed to be lightweight, strong in cold temperatures, costs needed to be kept to a minimum, and he needed parts quickly.”

As a result, Schultz and Protolabs selected 6061 aluminum due to its lightweight yet durable nature for competition. “This collaboration is truly special, it’s a testament to the advanced capabilities of digital manufacturing and what it can do to not only accelerate production, but also improve lives of those who are faced with adversity,” said Peters. “This is exactly the type of impact that we aim to have through our manufacturing grants and partnerships programs.”

About the Author

Peter Fretty

Technology Editor

As a highly experienced journalist, Peter Fretty regularly covers advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.