On the face of it, 3-D printing today is pretty easy.

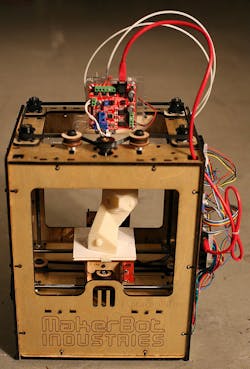

When MakerBot sold its first printer back in 2009, it arrived as little more than a wooden box filled with parts. It took 40 hours to get the thing assembled and running, and that's only if you really knew what you were doing.

A lot has changed since then.

As CEO and founder, Bre Pettis, explained at the ASME's Advanced Design & Manufacturing Impact Forum in Buffalo this week, since that first model took hold, the company's primary focus for every innovation, revision and iteration of its technologies has been to make the whole thing simple and easy.

"We spend more money making [3-D printing] easy than in a lot of other areas," he told the crowd. "That's the killer application: to be the easiest 3-D printer in the room, the most accessible, the one that gives you the least amount of fuss."

Looking at his product line five generations in, it looks like he might have succeeded in that mission. Or at least he's well on his way.

Today's MakerBots are closed boxes that arrive ready to run. They are filled with cameras and sensors with cloud applications and snap-in extruders. They boast slick, intuitive displays and controls that seem as simple and straightforward as any ink-jet printer.

They are as close to plug and play as it gets with today's technology. You just need a design, some material and you're off printing. It's a far cry from the old wooden box.

This is absolutely critical to MakerBot's future, Pettis argued. Because, he explained, the makers, hackers and geeks who shelled out that first generation machine are no longer the target consumers.

Pettis is after your children.

"Our goal," he said, "is to put a MakerBot in every school in the United States of America."

And he is well on his way, too. So far, he said they have put printers in about 3,000 schools across the U.S. – about 3% of the schools in the country.

That's not just a hook-them-young, cigarette-style marketing plan. It's something much, much bigger.

Solving Tomorrow's Problems

To Pettis, the MakerBot represents something much more than just a 3-D printer. It represents a new dimension of design, a new dimension of modeling. A new way to do manufacturing.

Don't let the simplicity fool you. 3-D printing requires a totally new way of thinking. It requires new structures, new concepts and new designs that can run against everything we know about traditional engineering.

It's not just a new tool for making things, he said, it's a tool that requires a new way of making.

And that is a tool better left to the next generation.

"The fact of the matter is, kids can innovate much better than we can," he said. "When students get ahold of this [technology] and they're going solve things that we don't expect. They're going to solve the problems that we don't even know are problems yet.

"We just have to give them the tools to do it."

At this point, Pettis said, the current generation of engineers who were brought up on 2-D design simply can't compete with the new generation of students that are playing with CAD and modeling practically from birth.

To master 3-D, he explained, engineers in the market now have to unlearn a lot of the rules they have come to accept and apply new strategies for the new technologies.

But for this new generation has nothing to unlearn. They are being exposed to CAD and modeling software before they have any other notions of traditional manufacturing. They are 3-D printing toys so often and so easily that doing so is a normal and natural part of life. It's simply the way things are done.

And that is unlocking a new and powerful generation of innovators and that will really, finally change everything.

"The next generation is going to know how to do your job before they go into college," Pettis said. "They're going to know how to use 3-D printing better than you will and they are going to enter the workforce at a much younger age."

A lot of that, he said, comes down to giving them the access to machines.

"I want to hire students who know how to innovate and solve problems – the ones that know how to actually do things," he said. "One of the ways we can do that is by putting 3-D printers in classrooms and letting them use them. So that's what we're doing."

The fact is, he explained, the next generation is going to beat us. They're going to solve the next generation's problems with these new tools. If they get access early and explore the new possibilities, he said, they can change manufacturing forever.

"In computer years, it's 1981 and there's one kid on the block with an Apple II Plus," he explained. "That's the kid that's going to get a job when they get out college."

About the Author

Travis M. Hessman

Editor-in-Chief

Travis Hessman is the editor-in-chief and senior content director for IndustryWeek and New Equipment Digest. He began his career as an intern at IndustryWeek in 2001 and later served as IW's technology and innovation editor. Today, he combines his experience as an educator, a writer, and a journalist to help address some of the most significant challenges in the manufacturing industry, with a particular focus on leadership, training, and the technologies of smart manufacturing.