Bioprinting Tissue for Human Transplantation Moving Closer with New Collaboration

Organovo Holdings Inc, a 3-D bioprinting technology company, announcement earlier this week it was collaborating with Yale School of Medicine, Department of Surgery to bring technology one step closer to bioprinting new tissues for human transplantation.

With a waiting list for critical organ transplants are three to five times as long as the list of available organs, it is an important development.

“Developing organs for surgical implantation will take meaningful efforts and focused partnerships,” said Keith Murphy, CEO of Organovo. “This collaboration with Yale, which combines their expertise and technology with our own, is one important step in progressing towards implantable, therapeutic tissues.

Ultimately, bioprinting tissues for cheaper, faster drug testing will help confirm bioprinted tissues can mimic natural function as well as inform how to bioprint larger tissues.

"We are excited to begin this collaboration with Organovo and are honored to be part of Methuselah's University 3D Bioprinter Program, which gives our key researchers access to cutting-edge 3D bioprinting technology," said Dr. John Geibel director of Surgical Research, and Professor of Surgery and Cellular and Molecular Physiology at Yale University. At Yale's School of Engineering & Applied Science and Yale's Department of Surgery clinicians and basic scientists are working to combine tissue engineering technologies with medical therapies.

The collaboration was made possible by a donation from the Methuselah Foundation, which is aa non-profit medical charity working to create a world where 90- year-olds can have the health profile of 50 year olds, by 2030.

Under Methuselah's University 3D Bioprinter Program, Methuselah is donating at least $500,000 in direct funding to be divided among several institutions for Organovo bioprinter research projects. This funding will cover budgeted bioprinter costs, as well as other aspects of project execution.

"We at the Methuselah Foundation have been a long-time supporter of academic and industry research in 3D bioprinting, regenerative medicine, and tissue engineering," said David Gobel, CEO of the Methuselah Foundation.

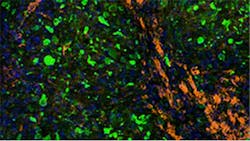

Organovo recently launched its initial product of the planned exVive3DTM portfolio offering, a 3D Human Liver Tissue for use in Toxicology and other preclinical drug testing. Additional products, including a 3D Kidney Model, are in development with anticipated release for use in the latter half of calendar year 2016.