The smartphone in your pocket. The laptop on your desk. The tablet on your workbench. They all comprise thousands of components and they're all mostly still hand-made. China's population is around 1.4 billion, so there's no shortage of workers to make all these complicated devices, but that cheap labor ain't as cheap as it was a decade ago.

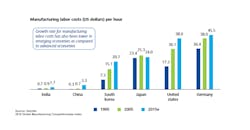

Take a look at this graph.

That jump doesn't seem like much compared to how much Western laborers make, but the percentage jump of manufacturing labor from 2005 to 2015 in China is 470% vs. America's 126%. So something's got to give, and it sure as heck won't be CEO salaries.

We all know the answer is robots, but that has been a bit difficult to implement universally.

"There's been a movement in the industry to start automating man-made products," starts Robert Little, CEO of ATI Industrial Automation. "In order to for them do that, they need robots. In order for those robots to be completely successful, they need force sensing feedback."

Sensing the force in this case requires no Jedi training, only a disc-shaped force/torque sensor attached at the wrist of the robot arm. ATI's force/torque sensors consist of a transducer, shielded high-flex cable, and intelligent data acquisition system, Ethernet/DeviceNet interface or F/T controller.

Photo: ATI

Unlike load cells, which only operate on a single axis and measure only push, these sense torque and side loads along all six axes.

"It's similar to a handshake," Little explains. "It can measure the touch and feel and gives life to robots. It's a feedback mechanism."

These sensors allow a doctor a continent away to perform surgery using a robot. The haptic feedback allows the robot to sense when it's made contact with tissue, and make precise incisions with the right amount of force in areas the surgeon cannot view.

If a sensor can do all that, actually animate an automaton and give it human-like touch, it's probably costly.

You'd be right. One of ATI's force-torque sensors can run $5,000 or more. But as Little notes, "A sensor that's expensive is less likely to be used."

And for factories wanting to get deeper into automation, their robots will need these sensors to do more of what those human laborers can do in terms of dexterity and efficiency, while only paying the purchase and integration price and routine maintenance costs.

Take a look at ATI Multi-Axis Force/Torque Sensors HERE.

Little says ATI's newest force/torque sensor, the Axia80, will provide everything an automated production line would want with one huge change: a 45% price drop.

Physically, all the electronics are built into the transducer, as opposed to being in a separate box outside of the robot. This keeps the cost down and footprint smaller, while excelling in accuracy, resolution, and robustness.

Another key to keeping the cost down is developing a way to mass produce the components, which are made in Apex, N.C.

New Equipment Digest is an IndustryWeek companion site within Penton's Manufacturing & Supply Chain Group.