Industrial Manufacturers Must Extract More Value from Digital Innovation

As Hannover Messe 2017 opens its doors, representatives of industrial companies from around the globe will once again enter a world of digital hi-tech as part of an annual imperative to learn about the latest industrial advances. This year, however, in addition to viewing the gleaming showcases there should be another imperative – extracting as much value from the experience as possible.

The world has become digitally connected to the point of no return, which means that industrial manufacturers can no longer afford to merely be impressed or engage in dreaming about the promise of industrial innovations. Instead they must act now to transform what they learn from Industry 4.0 and the Industrial Internet of Things (IIoT) into strong results for their business.

Business leaders are being bombarded with a dizzying array of unrelenting digital technology possibilities, largely propelled by demand for constant technical innovation. It is a form of “Industrial Consumerism” resulting from our tendency as consumers to adapt promptly to new ways of interacting and engaging with machines and devices, while looking for the next gap in the market to be filled by a device or software-solution. Moreover, increasing demand for outcomes versus product functionality is adding new complexity to the market as the outcome economy takes hold.

Yet, despite this formidable challenge, the progress of digital adoption by companies remains sluggish. Research conducted by Accenture for the World Economic Forum showed that 73% of the C-level executives interviewed were convinced that the IIoT would fundamentally change their industry, but just 20% had a thought-through strategy for harnessing it. Companies that want to succeed in the future must master the radical digital transition headed our way by opening themselves to a journey that will change their organization models beyond recognition -- the alternative being a catastrophic loss of market share and profitability.

Accenture has identified six fundamental digital “no regret” capabilities that can help manufacturers prevail against the digital disruption that will play a key role in the changing market. These capabilities form the basis for creating immediate value for an industrial enterprise facing the raging tech storm that will only become more intense. Companies should:

- Synchronize lifecycle clocks: Having a superior product lifecycle management approach is vital. During digitization, hardware, products, shop floor machinery and other production assets will age more slowly than the software that steers them. Increasing integration and synchronization of hardware and software cycles early-on will help avoid production complications later.

- Embed software intelligence and connectivity in sheet metal products to enable interaction with the production environment, such as people or machines, including other connected products. As an example of best practices, German industrial giant Siemens, having reached 75 percent digital automation in one of its plants, has been able to reduce its defect rate below 12 items per million produced, while increasing plant output 8.5 times with little change in employment.

- Use analytics to gain insights and decision support from data gathered by connected products and other data sources. Unhindered data flow, gathering, and data analytics will soon be the mainstay of highly digitized businesses. A manufacturer that does not use data analytics, even at a project level, will be at a major disadvantage.

- Make manufacturing agile by adopting industrial automation wherever possible to increase shop floor speed and flexibility. Automation already is transforming manufacturing in the automotive and industrial equipment industries with sensors and control mechanisms now embedded in most machinery.

- Transition to an “as-a-service” business to be prepared for the paradigm shift to the outcome economy, where combinations of products and services will no longer be acquired as property. Instead, they will be flexibly used as a service when required.

- Create ecosystems and run them. No single company will be in a position to own the whole digital value chain in an advanced outcome economy. Coordinating ecosystems of suppliers, customers, technology partners, start-ups, academia, competitors, and other stakeholders will be key.

Sustaining Success

Adopting these six core capabilities will be integral to achieving success in the new digital world. But, equally critical to that success will be having the ability to sustain it, which will require applying the engine of sustained performance – innovation.

Innovation’s role will be particularly important, as the market is shifting from a supply-side focus to a demand-side orientation. Today, customers no longer just expect bigger, better, faster or even smaller products and services. They want new and fluid service experiences that will necessitate companies developing a demand-driven approach that can anticipate and meet the fast and frequently changing needs of customers in near real-time.

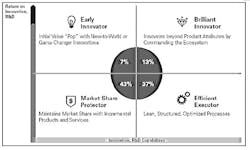

Accenture research has identified an innovation-driven growth model that shows four innovation approaches to satisfying the new market.

The first and most common is the Market Share Protector that basically follows the old innovation rule book, spending just enough on R&D to create product and service innovations that will maintain the same market share. The Efficient Executor is the next type, possessing more innovation efficiency, but not connected products, platforms and outside ecosystems needed to generate higher innovation returns.

Early Innovators are the third type. Their approach realizes increased returns due to their agile and responsive start-up-style innovation processes that lead to breakthrough innovations. Such innovations can change entire markets or carve out new market segments – thus producing higher returns than the first two innovators. The fourth type, the Brilliant Innovator, has the systematic innovation efficiency and innovative power to yield the highest returns, and is considered the role model for industrial manufacturers in the outcome economy.

Extracting Value for the Future

Hannover Messe is again providing insight into the next wave of digital transformation from which manufacturers can glean value to succeed in the new digital reality. But, doing so will require that they bridge the chasm between intent and action. New digital technologies are only as effective as the ability of industrial companies to make the most of the value they offer.

Eric Schaeffer is a senior managing director at Accenture. He is leading Accenture’s Digital Industry X.0 program with the objective of supporting industrial companies in harnessing digital opportunities – new services and business models – and transformation waves spanning across the whole enterprise. Schaeffer also leads one of Accenture’s global business services – Accenture Product Lifecycle Services – which provides end-to-end services to unlock value and efficiencies from product data across the engineering value chain, from the innovation and product development through to the manufacturing, aftersales and warranty services. His new book, “Industry X.0 – Realizing Digital Value in Industrial Sectors” will be published by Redline in May 2017.