Lessons in Lightweighting: Steel Still Easier on Air?

Lightweighting has always been important in the automotive industry. The lighter a vehicle is, the easier it is for the power systems to make it go and the braking systems to make it stop. It’s just basic physics. For more than 100 years, the internal combustion engine has been the power system of choice in the automotive industry, because it is cost-effective, relatively efficient and uses a readily available and often affordable fuel – gasoline.

Luxury sports cars through the years have focused on lightweighting and utilizing a variety of materials to achieve the lightest vehicles possible. These mass-efficient designs are great for acceleration, which is a critical performance metric in these vehicles. However, this comes at a high cost to the consumer.

The importance of weight reduction for the average vehicle has varied. At first, it depended on the cost and availability of gasoline, but eventually expanded to increasingly stringent safety requirements (which added significant mass to body structures) and fuel economy regulations intended to reduce dependency on foreign oil and on tailpipe emissions. As a consequence of environmental and climate change studies, the issue of tailpipe greenhouse gas (GHG) emissions has become a significant global concern for which many countries have adopted regulations and standards.

There are many ways to reduce tailpipe emissions, including improved fuel efficiency through improved powertrain systems and aerodynamics, and reduced rolling resistance and weight, to name a few. Automakers throughout the world have been improving in each of these areas for several years. However, GHG emissions continue to rise.

This can be expected as the number of vehicles increases globally. But one must also pause and ask: Has something else changed?

The best way to answer this question is to look at the whole picture, or in this case, perform a life cycle assessment on lightweighting vehicles.

The Steel Market Development Institute (SMDI) and Steel Recycling Institute (SRI), both business units of the American Iron and Steel Institute, along with WorldAutoSteel, recently did just that. These groups have been studying the impact of emissions and energy consumption in lightweighting vehicles with various materials for several years. Steel is a large portion of the material used in today’s high volume vehicles. In fact, over 50% of an average vehicle is made of steel, the dominant material for body structures, chassis and suspension components, and closure panels, such as doors, hoods and fenders. Once you add the steel components in the engine and transmission, steel makes up more than three-quarters of the vehicle weight.

Rise of Steel

Steel became a dominant material in the average automobile in the 1930s, when automakers discovered steel has better performance than wood for body structures (it was already being used for closure panels). It was cost-effective and plentiful, and the railroad and construction industries had been using steel for decades. The combination of steel’s high strength and durability performance, along with its low cost, has enabled steel to remain a preferred metal for vehicles.

In addition, the steel industry has continued to innovate and develop new steel grades to provide increased strength. When using newer high-strength and advanced high-strength steel grades, not only can automotive engineers design a vehicle with higher performance, but they can do so at a lower mass since less steel (in the form of a thinner sheet) is needed. In fact, the industry has increased steel’s strength 10 times since the 1970s.

Hidden Costs of Steel Alternatives

With increasingly stringent mandates to improve fuel economy and reduce tailpipe emissions, automakers are feeling pressured to use alternate materials for lightweighting, such as aluminum and carbon fiber reinforced polymers (CFRP). These materials can provide additional lightweighting over advanced high-strength steels, but at a significant cost to the consumer and to the environment.

The cost impact is simple. Aluminum costs about two-to-three times the cost of steel and CFRP is about six-to-ten times more costly. There has been much research done to reduce the cost of these alternative materials. However, there will always be a significant difference in the costs as a result of the amount of energy needed to make the raw materials. Aluminum requires seven times the energy of steel when processing from ore, and producing CFRP uses even more energy.

The assessment of the environmental impact is also straightforward, but must take all aspects of a vehicle’s life into consideration. This includes not only the use phase (tailpipe emissions) but also production (materials and vehicle assembly) and the vehicle’s end-of-life (recycling/disposal).

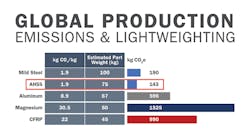

For example, take a baseline vehicle mainly constructed of various grades of steel and lightweight it with aluminum, CFRP or optimized use of advanced high-strength steel. Generally, although less aluminum and CFRP will be used by mass, because the greenhouse gas (GHG) emissions that result in production of the materials are so different, the optimized steel solution will produce the lowest GHG emissions for this phase. The chart below shows the difference in global production GHG emissions for making a kilogram of each material along with the amount of mass reduction that can typically be achieved with each material. Because of the lower energy needed to make steel, it clearly has an advantage.

The difference in the mass of the lightweighted vehicle versus the baseline will also reduce the fuel consumption, and thus tailpipe emissions. However, it has been shown that lightweighting a vehicle’s body and closures with aluminum only achieves around a 0.5 MPG improvement. This small difference requires the vehicle to be on the road at least 10-12 years or more to make up for the significant difference in material production phase GHG emissions.

Recyclability

A vehicle’s end-of-life phase completes the life cycle story. Steel is the most recycled automotive material in the world. It’s easy to sort by magnets and it can be re-melted into any of the over 200 grades currently available to the automotive industry as well as any other steel product made today. Aluminum must be sorted or downgraded when re-melted for automotive use, and CFRP is mostly disposed of, but may be chopped up and used for other applications.

The peer-reviewed studies by SMDI/SRI clearly show lightweighting with steel achieves the lowest overall GHG emissions at the best cost to the consumer. When focusing on tailpipe emissions alone, the results of lightweighting vehicles with alternative materials can lead to an unintended increase of total GHG emissions over a vehicle’s life cycle. Should we really pay more for vehicles that make the environment worse?

Jody N. Hall Ph.D., is vice president, of the automotive market for the Steel Market Development Institute, where she is responsible for leadership of the Automotive Applications Council, a group of member steel producers, in automotive research, education and technology transfer activities. She also coordinates the steel input to the Auto/Steel Partnership (which has car company members including FCA US LLC, Ford Motor Company and General Motors Company), and other steel-related consortia.

About the Author

Jody N. Hall

Vice President, Automotive Market

Jody N. Hall Ph.D., is vice president, of the automotive market for the Steel Market Development Institute, where she is responsible for leadership of the Automotive Applications Council, a group of member steel producers, in automotive research, education and technology transfer activities. She also coordinates the steel input to the Auto/Steel Partnership (which has car company members including FCA US LLC, Ford Motor Company and General Motors Company), and other steel-related consortia.