Future Factory: Ants, Butterflies and the Occasional Chameleon

Most robots used in manufacturing consist of a large metal arm used to move heavy components on an assembly line or perform functions such as welding or parts picking. But visit the Festo booth at Hannover Messe and what you'll see seems more out of a zoo than an industrial scene.

Using nature as their inspiration, Festo engineers have developed several robots and devices that mimic the behavior of animals. For example, the company has developed BionicANTs that communicate with each other and coordinate their actions. The ants, about 5 inches long, make their own autonomous decisions but coordinate with each other to perform tasks.Their activities are based on a set of rules developed using mathematical modeling and simulations and are stored in each ant.

"The control strategy provides for a multi-agent system in which the participants are not hierarchically ordered," a Festo document explains. "Instead, all the BionicANTs contribute to the process of finding a solution together by means of distributed intelligence."

A radio module and Cortex M4 processor inside each ant allow them to communicate with each other. Piezoelectric actuators move each ant's six legs and the pincer jaws in its head. The ants use a 3D stereo camera and a sensor in the abdomen to "see" where they are and determine their position.

Festo sees the application of this technology in factories where production systems are based on intelligent components that react to different situations and flexibly operate to customize output. "Tasks that are now managed by a central master computer will be taken over by the components in future," Festo predicts.

eMotionButterflies are Freed

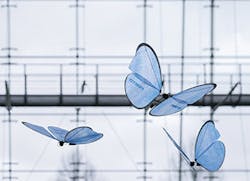

Ants aren't the only animal-based robots roaming the Festo display area. Flying overhead are eMotionButterflies, pale green creatures that demonstrate how the real and virtual worlds can operate together.

Festo says the eMotionButterflies "illustrate complex topics from the world of future production such as functional integration, ultra-lightweight construction and above all real time-optimized networked communication between individual systems."

Festo also is showing the FlexShapeGripper, a robot gripper based on a chameleon's tongue. When an chameleon sights its insect prey, Festo explained, it shoots out its tongue like an elastic band and draws in the insect. The FlexShapeGripper can grip different shapes through use of a water-filled silicone cap which wraps around items. Pneumatics control the gripping and release mechanism.

"In the production of the future, increasingly flexible systems and components will be required that autonomously adapt to individual products. Adaptable grasping devices like the FlexShapeGripper can assume a significant role in this process," Festo states.

About the Author

Steve Minter

Steve Minter, Executive Editor

Focus: Leadership, Global Economy, Energy

Call: 216-931-9281

Follow on Twitter: @SgMinterIW

An award-winning editor, Executive Editor Steve Minter covers leadership, global economic and trade issues and energy, tackling subject matter ranging from CEO profiles and leadership theories to economic trends and energy policy. As well, he supervises content development for editorial products including the magazine, IndustryWeek.com, research and information products, and conferences.

Before joining the IW staff, Steve was publisher and editorial director of Penton Media’s EHS Today, where he was instrumental in the development of the Champions of Safety and America’s Safest Companies recognition programs.

Steve received his B.A. in English from Oberlin College. He is married and has two adult children.