Technology: The Problem with 3-D Printed Material

"We've invented this new machine and it's awesome."

That's how Greg Mark, founder and CEO of MarkForged, introduced the world to the first carbon fiber 3-D printer -- the Mark One -- in January.

With it, Mark gave the market a machine capable of printing the strongest, lightest and most promising 3-D material developed to date. Which really is awesome. But limiting the awesomeness to just the machine is selling it short.

With Mark One, Mark and his MIT-plucked team created a whole new 3-D printer market out of an idea (and a fair helping of startup cash) with sheer ingenuity and skill. That's how the 3-D printing industry is supposed to work: fast-paced, disruptive start-ups changing the world.

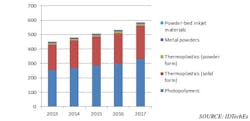

But new data coming out of market research firm, IDTechEx, suggests that might not be the case anymore -- at least as far as materials are concerned.

See Also: Manufacturing Industry Technology News & Trends

"Innovative small companies entering the market with novel materials are finding it hard to get traction," explains Wendy Kneissl, senior technology analyst at IDTechEx and author of the new report, "3D Printing Materials: 2014-2025."

She warns, "This might well drive consolidation (and failure) of such small companies in the near future."

2-D Models in a 3-D World

The problem, she says, is that established 3-D printer manufacturers have cornered the materials market by requiring proprietary spool inserts for their printers. That creates a monopoly that both locks users into expensive, branded supplies after the purchase and prevents newbies like MarkForged from breaking in.

That should sound familiar. It is the same model used today in 2-D inkjet printers, Kneissl says, in which "end-users are locked into the 'ink cartridges' of the manufacturers." As a result, she explains, "Not only are prices of fairly standard polymers too high, [they] hinder development of new materials."

For the industry, Kneissl writes in her report, any downward pressure on material prices in the near future will be driven mainly by new entrants into the additive manufacturing area.

However, she adds, "Barriers to entry for third-party materials suppliers are high, and those who do enter the market are unable to get the economies of scale required to accelerate both material development and progress towards a competitive market."

So the industry is caught on this snag: It needs startups and new ideas to push forward, but it is locked up in 2-D pricing strategies that inhibit those same developments -- a predicament the industry is going to have to solve fast to stay relevant.

The scenario gives Greg Mark's closing words to his Mark One promo an ominous tone:

"We've now enabled you to print carbon fiber," he says. "God knows what you're going to do with it."

About the Author

Travis M. Hessman

Editor-in-Chief

Travis Hessman is the editor-in-chief and senior content director for IndustryWeek and New Equipment Digest. He began his career as an intern at IndustryWeek in 2001 and later served as IW's technology and innovation editor. Today, he combines his experience as an educator, a writer, and a journalist to help address some of the most significant challenges in the manufacturing industry, with a particular focus on leadership, training, and the technologies of smart manufacturing.