3-D Printing Could Herald New Industrial Revolution

GENEVA -- As potentially game-changing as the steam engine or telegraph were in their day, 3-D printing could herald a new industrial revolution, experts say.

For the uninitiated, the prospect of printers turning out any object you want at the click of a button may seem like the stuff of science fiction.

But 3-D printing is already here, is developing fast, and looks set to leap from the labs and niche industries onto the wider market.

"There are still limits imposed by the technology available today," said Olivier Olmo, operational director of Switzerland's EPFL research institution.

"But I'm certain that within 10 or 20 years, we'll have a kind of revolution in terms of the technology being available to everyone," he said.

The concept's roots lie in fields ranging from standard two-dimensional printing to machine-tooling.

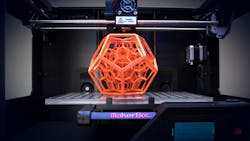

First, a 3-D digital design is created either from scratch on a computer or by scanning a real object, before being cut into two-dimensional "slices" which are computer-fed into a printer.

The printer gradually deposits fine layers of material – such as plastic, carbon or metal – and builds a physical object.

The product can be as hard or as flexible as you program the printer to make it, and even include moving parts rather than being a solid block.

"In theory, anything that we have today can be produced through 3-D printing. It may just alter manufacturing as we know it," said Simon Jones, a technology expert at global law firm DLA Piper.

In addition to the potential ecological impact of producing products right where they are needed, Jones said, 3-D printing could make small-scale production of objects cheaper, rather than turning out huge numbers which may go to waste.

Beyond Replication

The uses go beyond easy replication of things that exist already.

"The technology offers possibilities that available manufacturing does not," said Carla van Steenbergen of i.materialise, a Belgium-based service that prints designs for users.

Van Steenbergen pointed to objects such as customized screws for broken bones which match a patient's specific anatomical characteristics and thereby cause less deterioration than the traditional variety.

"It's the kind of thing that traditional technology won't allow. It's the kind of area where the big added value lies, making the impossible become possible," she underlined.

The technology has been around for longer than many would think: the first commercial 3-D print technology, known as stereo-lithography, was invented in 1994.

It has taken time to inch into the limelight, however.

"It's honest to say that 3-D printing is far from the mainstream, but it's a sign that something is happening," said Tristan Renaud of Prevue-Medical, a company that turns out models from 3-D medical imaging data.

His technology chief Erik Ziegler said using online 3-D printing services was likely to remain the norm for a while, given printer costs.

An alternative is provided by "Fablabs" – short for "fabrication laboratories" – a concept created by the Massachusetts Institute of Technology that offers grassroots access to small-scale manufacturing facilities.

But for those tempted by home-output, a handful of 3-D printers have hit the consumer market, retailing for around $2,000.

As with computers, the price is expected to fall over time as demand rises and technology advances.

Van Steenbergen said that at the industrial level, 3-D printing is not set to take over from classical methods, but rather go hand in hand.

"I think it will affect the manufacturing of some products, but it's never going to replace it," she said.

It also raises a raft of questions.

For example, would a car manufacturer be ready to let a neighborhood mechanic print spare parts? And if such goods were produced under license, what quality guarantees would be offered to consumers?

On the intellectual property front, what constitutes fair production of a replacement part for something you already own? And would designers of 3-D objects be protected from an equivalent of file-sharing, bemoaned by the music industry?

"We'd tend to see an increase in commercial impact," said Jones. "It would be very difficult to prevent that once 3-D technology got to a cost point that's sensible."

Francis Gurry, head of the UN's World Intellectual Property Organization, underlined that the global 3-D printing business is forecast to be worth $3.7 billion by 2015.

In contrast, world merchandise exports were worth $18.3 trillion last year, and commercial services, $4.3 trillion.

Despite remaining small in global terms, Gurry noted, the value of 3-D printing is expected to expand relatively fast, to $6.5 billion by 2019.

- Jonathan Fowler, AFP

Copyright Agence France-Presse, 2013

About the Author

Agence France-Presse

Copyright Agence France-Presse, 2002-2025. AFP text, photos, graphics and logos shall not be reproduced, published, broadcast, rewritten for broadcast or publication or redistributed directly or indirectly in any medium. AFP shall not be held liable for any delays, inaccuracies, errors or omissions in any AFP content, or for any actions taken in consequence.