On August 25-26, 2016, the 12th annual Lean Accounting Summit was held in San Antonio, Texas. I was honored to be invited to speak for the third time as a representative of the Reshoring Initiative on "How to return manufacturing to America" during one of the four breakout sessions on the first day.

The conference started Thursday morning with a keynote presentation by Mark Graban on "Practicing Lean." Mark is an internationally recognized expert in the field of "lean healthcare" as a consultant, author, keynote speaker, and blogger. His new book, Practicing Lean, reflects on more than 20 years of trying to get better at lean in manufacturing and healthcare.

Mark's first point for the audience to ponder was, "Are we practicing lean? He answered his rhetorical question, saying, "Lean is a learning process. It is a learning experience that develops skills and knowledge. We need to try to stop using the word ‘implement’ because it implies being done. ‘Practicing’ implies continuous learning. Learning by doing ─ with a qualified coach. I've been learning lean ─ I didn't learn lean."

A few other points he made were: "We are all human so we make mistakes, but we need to stop repeating the same mistakes. Are we doing lean or LAME (Lean as Mistakenly Explained)? We all start somewhere. We need help to do better. Don't ask what tools should I start with ─ start with the need. Talk about the current state to find the need. You don't have to always start the same way ─ 5S isn't always the best tool to start with. Learn but don't just copy what someone else has done. In healthcare, it's important to get it right the first time ─ mistakes can cost lives."

Overcoming the Accounting Roadblock

Later, I attended "Bridging the gap between accounting and operations," presented by Jerry Solomon, who is a founding thought leader and subject matter expert in lean accounting, author of three lean books, and a three-decade teacher and lean practitioner.

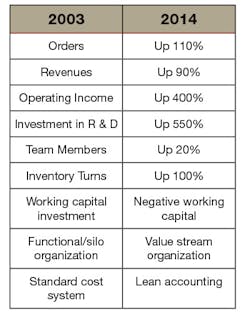

He told the story of MarquipWardUnited, a division of Barry-Wehmiller, Inc. in Hunt Valley from 2003 to 2014 when he was V.P. of Operations. The highlights from his presentation were: "Lean focuses on safety, quality, delivery, cost, elimination of waste, and respect for people. How is it typically implemented versus how should it be implemented? It should mean no layoffs. Lean requires a C-level champion, organization by value streams, recognition, empowerment, coaching, training, inspiring leadership, and lean accounting. Lean accounting is applying lean tools to eliminate waste and frustration in accounting ─ ‘plain English’ financial reports. Accounting is often one of the biggest roadblocks to a successful lean transformation. In a lean journey, the greater the initial success with lean, the more likely earnings will be negatively impacted. Lean is not a cost reduction program ─ it is a cash flow generator, a capacity generator and most of all, a people system. The benefits of lean are based on how these improvements are utilized!"

Here is how MarquipWardUnited changed from 2003 to 2014:

Reshoring Update

After lunch, I gave my own presentation, incorporating the latest data on reshoring provided to me by Harry Moser, founder of the Reshoring Initiative. According to this data, the top countries from which products are being reshored are: China, Mexico, Canada, Taiwan, Japan, and India. The top 10 states to which products are being reshored are: South Carolina, Texas, Kentucky, Georgia, Tennessee, Ohio, Michigan, New York, North Carolina, Kansas and Pennsylvania. Notice that Michigan and New York are in the top 10 even though they are not low cost regions to conduct manufacturing. Even though California ranks dead last on the Small Business Survival Index, it ranks 12th in reshoring. The main advantages for reshoring are:

- Faster lead times - 49-50% reduction

- Delivery accuracy - 30-40% improved

- Unforeseen disruptions - companies can respond swiftly

- Volatile demand - closer proximity increases agility

- Competitiveness - better at serving local markets while maintaining low costs

I also attended "The Lean Management System" presented by Joe Murli, president of The Murli Group LLC. His career includes extensive coaching by retired Toyota executives when he was at Pratt & Whitney, being general manager at Chengdu Aerotech (joint venture of UTC and a Chinese company), director of N.A. operations at Ensign Bickford, and president of Manufacturing at Kaman Corp. before founding his company in 2003.

He said, "Lean management is about unlocking the human potential. Why do it? Always start with a need. In 1990, Pratt &Whitney went from 30,000 employees to 20,000 in 18 months because of the end of the Cold War and cuts in defense spending. Toyota people came to visit P&W, and I was responsible for showing them around for a week. After that P&W hired a lean consultant to go lean.

“We did a Kaizen event every other week at every plant around the world. We changed into cell manufacturing, but when we returned later, it hadn't been sustained. Why? The team members hadn't bought into the change. Nothing is more important than every member of the team seeing the problem.

“Later, I did an extensive overview of different management systems. The distinguishing factor in lean is continuous improvement. It is a system of continual improvement. True North inspires and nurtures the human spirit with a vision, mission, and purpose. True North is standard work, visual management, 5S, etc. In standard work, you find a problem, solve it, and then establish one best way as the one agreed upon."

He explained that lean is a people system and human resources needs to be part of the transformation from the start: from recruitment, how you promote, how you compensate, etc. To establish leader standard work and behaviors, you need to be humble, appreciative, ask open-ended questions, etc. Accountability comes through: transparency, facts, fast identification of problems, overt problem solving, team learning, and continually improving." He asked to whom are we accountable and answered: "our customers, our investors, our employees, and society."

Moving Beyond Budgeting

The next presentation I attended was "Why Lean requires moving beyond budgeting" by Steve Player, director of Beyond EPS Advisors, a business consulting firm, and founder of Live Future Ready – a member-based community of practice that implements more effective ways to plan and control operations.

Steve said, "Stop doing dumb stuff! Monthly close of statements is dumb. Live Future Ready's ambition is to help people plan for the future. Traditional budgets block your efforts to become lean. There is waste in budgeting: rework, overproduction, defects, unnecessary processing, waiting, and design doesn't meet needs. DVF > R, where D = Dissatisfaction, V= Vision, F= Known first steps, R = Resistance to change. The problems with budgets are: takes too long, based on inaccurate assumptions, triggers unnecessary spending, gives the illusion of control, causes gaming that erodes ethics, it brings out the most unproductive behaviors, and it costs too much."

The Beyond Budgeting principles are:

- Values - bind people to a common cause

- Governance - govern through shared values and sound judgment

- Transparency - make information open and transparent

- Teams - organize around seamless network of accountable teams

- Trust- trust teams to regulate and improve performance

- Accountability - base on holistic criteria and peer reviews

- Goals - set ambitious medium goals

- Rewards - base rewards on relative performance

- Planning -make it continuous and inclusive

Steve added, "Planning is changing from the ship you are to the ship you want to be. Need to transform while delivering on a day to day. Target rolls with the market. Command and control vs. adaptive. Revolutionary approach - change is very fast - 12 to 18 months. Evolutionary -more gradual, 2 to 5 yrs. Check, plan, act. Forecast vs. target - rolling forecast.”

The next session I attended was "Moving Beyond Budgets at Holt Cat" presented by Gretchen Stepke, director of Business Systems, and Susan Nufer, controller - Dealership Operations. Holt Cat is a family-owned business, founded in 1983 and is a Caterpillar dealership. They acquired another dealer in 2002 and created a team to evaluate their systems. They began searching for a budgeting system and selected Clarity Systems in 2004 to get more reliable data than what was available using Excel spreadsheets.

They shared that they had 23 years of growth until 2009 when they hit the trough. They assembled their leadership team and a new plan was made. They worked with Steve Player and switched to rolling forecasts and declared budgeting dead. Forecasting became a better tool. Seven keys to better forecasting are:

- Your job of influencing is never done

- Use language that helps people to change

- Try to eliminate "budget" from vocabulary

- Desire to grow helps move to forecasting

- Change takes time

- Processes are getting formalized to drive the organization.

- You never stop learning

They went to basics: how many people do we need, what resources do we need, etc. They applied the 12 Beyond Budgeting principles. Goals and rewards are the most difficult. They are a member of the Beyond Budgeting Roundtable.

CAT dealers have a benchmarking system (DFRS) to use to compare themselves to other CAT dealers They developed Ace and Pulse reports and worked to break down silos. In 2010, they had a 33% increase in sales and reduced expenses by 1%. Using forecasts, they are achieving target goals. Now they are powering for the future: new locations, focus on excellence, and growing the "core." They have added lines, such as Link belt, in order to grow. They have outgrown Clarity and are looking at new tools.

Lean Product Development

The last session of the summit I attended was "Transforming from the inside out," presented by Norbert Majerus, who has been Goodyear’s lean champion in research and development for nearly a decade and implemented a principles-based lean product development process at the three global innovation centers of Goodyear Tire & Rubber Co.

Norbert said, "Goodyear releases about 1,500 new, innovative SKUs per year. Lean applies to the innovation process just as much as to manufacturing or finance. The principles are the same; the problems are identical. It all starts with the people." He then shared how they managed people. He said, "We started more than 10 years ago and focused on principles, not the tools. We manage people through changing. Change in culture takes time. It is not done by the organization chart. Most of the time it is easier to teach lean to people doing the work than to teach lean experts how to do work." He shared his 11 steps to a lean culture:

- Do your homework

- Get leverage

- Engage the right people to lead change

- Develop a vision and make plans

- Get support

- You cannot over-communicate or over-train

- Deal with resistance

- Engage the employees

- Do good things and talk about them

- Remember PDCA

- Sustain the change.

In conclusion, he said, "Communication and training are critical. Motivation makes work easier. Involve people in change. Show respect and interest in people, not just in results. Engage people by communicating, teaching, and teaching again. Listen to their concerns, focus on influencers, and build trust. Telling people the solution is disrespectful and takes away the opportunity to learn. Make traditional leadership work so easy that they have time to do lean. Don't use lean to eliminate jobs."

I wish all of my readers could have attended this conference as there were more stories of successful transformations than at the two previous conferences I attended. After the summit, Lear Frontiers put together a "Next Steps" page that includes six free videos designed to engage various business functions:

- What is Lean Accounting?

- What is Lean Sales & Marketing?

- What is Lean Product Development?

- What is Lean HR?

- What is Lean IT?

- What is a Lean Supply Chain?

You can view the videos at this link: http://laslms.leanfrontiers.com/nextsteps/

I can't stress enough the importance of your company beginning the lean journey ─ it is a key step to being competitive in the global marketplace and being able to return more manufacturing to America.

About the Author

Michele Nash-Hoff

President

Michele Nash-Hoff has been in and out of San Diego’s high-tech manufacturing industry since starting as an engineering secretary at age 18. Her career includes being part of the founding team of two startup companies. She took a hiatus from working full-time to attend college and graduated from San Diego State University in 1982 with a bachelor’s degree in French and Spanish.

After graduating, she became vice president of a sales agency covering 11 of the western states. In 1985, Michele left the company to form her own sales agency, ElectroFab Sales, to work with companies to help them select the right manufacturing processes for their new and existing products.

Michele is the author of four books, For Profit Business Incubators, published in 1998 by the National Business Incubation Association, two editions of Can American Manufacturing be Saved? Why we should and how we can (2009 and 2012), and Rebuild Manufacturing – the key to American Prosperity (2017).

Michele has been president of the San Diego Electronics Network, the San Diego Chapter of the Electronics Representatives Association, and The High Technology Foundation, as well as several professional and non-profit organizations. She is an active member of the Soroptimist International of San Diego club.

Michele is currently a director on the board of the San Diego Inventors Forum. She is also Chair of the California chapter of the Coalition for a Prosperous America and a mentor for CONNECT’s Springboard program for startup companies.

She has a certificate in Total Quality Management and is a 1994 graduate of San Diego’s leadership program (LEAD San Diego.) She earned a Certificate in Lean Six Sigma in 2014.

Michele is married to Michael Hoff and has raised two sons and two daughters. She enjoys spending time with her two grandsons and eight granddaughters. Her favorite leisure activities are hiking in the mountains, swimming, gardening, reading and taking tap dance lessons.