Here's a simple formula: For every 10% reduction in the mass of a vehicle, you get a 6% to 8% boost in a vehicle's fuel economy.

What's not so simple (and what has proven elusive for the auto industry thus far) is how to produce a low-mass vehicle that meets safety standards and performance expectations -- at a reasonable cost for automakers and consumers.

The engineering arm of British sports-car maker Group Lotus PLC might have cracked the code, however, by leveraging emerging technologies, advanced materials and process innovation.

See Also: Manufacturing Innovation & Product Development Strategy

As part of a study commissioned by the California Air Resources Board, Lotus Engineering used computer-simulation modeling to develop a virtual crossover utility vehicle based on the interior and exterior dimensions of a 2009 Toyota Venza.

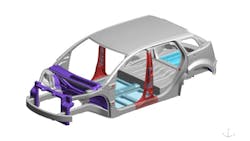

In a report published in August, the firm concluded that it is commercially feasible to develop a CUV that has 31% less mass and is 37% lighter than the baseline Venza, while meeting or exceeding standards for size, cargo volume, comfort, crashworthiness and structural integrity.

"The majority of the processes and materials for the [virtual vehicle] are in use today," the firm said in the report.

Although the use of composites and other advanced materials drove up the body-in-white costs of the low-mass vehicle by 35%, Lotus was able to offset most of those costs by taking a "holistic" approach to the vehicle's design and assembly, Gregg Peterson, senior technologist for Lotus Engineering, explained during a presentation at NASA's Technology Days in Cleveland last month.

"We did a very high level of integration to be able to eliminate parts and merge parts together and get rid of nonfunctional parts and make nonstructural parts structural, so that every part contributed to the body rigidity," Peterson said. "And the bottom line is that we projected about a 3%-plus-cost hit for the total vehicle as a result of this for a 37% lighter vehicle."

One of the techniques used to assemble the vehicle body -- which incorporates magnesium, aluminum, composites and steel -- is structural adhesive bonding, a process already employed in Lotus's automotive plants.

"No. 1, it allowed us to get rid of the welding process," Peterson said. "No. 2, we saved weight because we were able to reduce the flange thickness by about 30% compared with resistance spot welds."

Lotus also discovered cost-saving opportunities in green materials. Lotus used recycled polyethylene terephthalate, or PET, plastic -- commonly found in water bottles -- as the basis for the vehicle's 18-millimeter-thick laminated floor pan.

Inspired by the study's results, Lotus conceptualized what it would take to create an ultralight "world car" with a projected fuel economy of 120 mpg, Peterson said. The world car would feature an aerodynamic design, 1+2+1 seating and a minimalistic interior -- the driver's laptop or smartphone would function as the instrument panel.

"We think it's relatively realistic to expect to see a car of this weight for $15,000 in three or four years, when the cost of fuel might be $5 or $6 or even higher than that," Peterson said.

About the Author

Josh Cable

Former Senior Editor

Former Senior Editor Josh Cable covered innovation issues -- including trends and best practices in R&D, process improvement and product development. He also reported on the best practices of the most successful companies and executives in the world of transportation manufacturing, which encompasses the aerospace, automotive, rail and shipbuilding sectors.

Josh also led the IndustryWeek Manufacturing Hall of Fame, IW’s annual tribute to the most influential executives and thought leaders in U.S. manufacturing history.

Before joining IndustryWeek, Josh was the editor-in-chief of Penton Media’s Government Product News and Government Procurement. He also was an award-winning beat reporter for several small newspapers in Northeast Ohio.

Josh received his BFA in creative writing from Bowling Green University, and continued his professional development through course-work at Ohio University and Cuyahoga Community College.

A lifelong resident of the Buckeye State, Josh currently lives in the Tremont neighborhood of Cleveland. When the weather cooperates, you’ll find him riding his bike to work, exercising his green thumb in the backyard or playing ultimate Frisbee.