Univ of Michigan, Ohio State Team Up for High Tech Manufacturing Research

President Obama announced on Saturday the creation of a manufacturing institute to open this spring in Metro Detroit. The $148 million American Lightweight Materials Manufacturing Innovation Institute (ALMMII) is expected to bring 10,000 jobs to the region within the next five years

The institute will be led by the University of Michigan, Ohio-based manufacturing technology nonprofit EWI and The Ohio State University. In addition to the lead partners, more than seven universities, 17 non-industry members, and 30 companies–including Alcoa, Boeing, Honda, and General Electric–will participate in the collaboration. Its main office will be in Canton, Mich., with key support in Columbus, Ohio.

"Through this initiative, our region will build on its core strengths to become the nation’s technology hub for lightweight materials and manufacturing,” said U-M President Mary Sue Coleman. “Companies from around the country will come here not only because of our technological capabilities, but also because we have the workforce they need in their efforts to revitalize and transform domestic manufacturing."

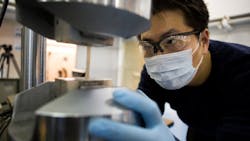

The institute is designed to establish an ecosystem to support the production of advanced lightweight metals. It will enable research and development projects as well as education and training programs to prepare the workforce. It is expected to have both national and regional impacts.

"We are extremely excited to be a part of this national institute, which will bring together resources from industry, government and academia to enhance the region's competitiveness, create research and workforce training opportunities for students and generate economic growth. I cannot think of a more fitting collaboration to bring together Ohio State and Michigan," Joseph A. Alutto, interim president, The Ohio State University said.

ALMMII is charged with moving cutting-edge lightweight metals out of the research lab and into tomorrow’s cars, trucks, airplanes and ships for both the commercial and military sectors. Lighter vehicles for the military, industry and consumers, alike, have better performance and use less fuel. They can carry larger loads and travel the same distances at lower cost and with fewer carbon emissions.

The institute’s efforts will encompass the entire transportation supply chain, nurturing innovations from conception through design, development and production. It will contract more than $100 million in R&D projects with partner organizations.

And by establishing science, technology and engineering curricula for programs in grade school to graduate school, the institute will help educate the next generation of manufacturing operators and engineers.

Most of the 10,000 jobs it’s expected to create will be in the metal stamping, metalworking, machining and casting industries that are dominant in the Midwest region.

It will aim to add 100 more metal-related engineering professionals per year and 1,000 more skilled trade workers. Within three years, it should be offering advanced training to an additional 1,000 current employees per year.

The challenge is in optimizing component designs and developing the advanced processes to manufacture them robustly on a large scale at affordable cost,” Taub said. “And each material needs its own tailored process.”

The institute will be the newest node in the National Network of Manufacturing Innovation, a White House initiative to help U.S. manufacturers become more competitive. The concept of such a network came out of President Obama’s Advanced Manufacturing Partnership, launched in 2011. Coleman and engineering professor Jack Hu, now U-M’s interim vice president for research, served on the working group that recommended the innovation network.

The American Lightweight Materials Manufacturing Innovation Institute is funded through the Lightweight and Modern Metals Manufacturing Innovation (LM3I) program. It was selected through a competitive process led by the U.S. Department of Defense, and will receive $70 million in federal funding over five years, matched by another $78 million from the consortium partners themselves. The funding includes $10 million from the Michigan Economic Development Corporation and additional dollars from the state of Ohio.