Inventors Say New Material Achieves Record for Converting Waste Heat to Power

Scientists in the United States on Wednesday reported making a souped-up material that beats the record for converting waste heat into power, an exploit they hope will be incorporated into clean energy investment.

Described by an independent commentator as "a giant leap," the material achieves the highest efficiency ever for scavenging heat from a source and transforming it into power, its inventors said.

As much as 15% to 20% of the heat that disappears out of car tailpipes and the chimneys of power stations and factories could be recovered as electricity, they believe.

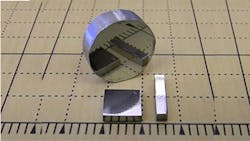

The compound is a derivative of lead telluride, a semiconductor first used in the Apollo moon landings to provide astronauts with a renewable, thermoelectric power source.

For years, the efficiency rating in thermoelectrics, known by the unit of ZT, stagnated at 1.

The new material has a ZT rating of 2.2, outstripping the previous record, reached earlier this year, of 1.7.

"At this level there are realistic prospects for recovering high-temperature waste and turning it into useful energy," said Mercouri Kanatzidis, a chemistry professor at Northwestern University in Chicago, who led the study appearing in the journal Nature.

Cost is Hard to Measure

In an email exchange with AFP, Kanatzidis said it was hard to estimate the cost of the new material, made from the elements lead and tellurium, but that if manufactured on a large scale, "it should be nearly the same as bulk lead and tellurium combined."

He also discounted fears of toxicity, saying that the lead-tellurium bond was "very stable environmentally" -- the compound occurs naturally as a mineral called altaite.

Nanotechnology Aids Breakthrough

The breakthrough, says the study, comes from combining several techniques to doctor the material, including the use of sodium and nano-particles of strontium telluride, to dampen scattering of electrons and make energy conversion more efficient.

The work was hailed in a commentary in Nature by Tom Nilges, a chemist at the Munich Technical University in Germany, who said it was "a feat that is not only a tremendous step for one group, but also a giant leap for thermoelectrics."

Copyright Agence France-Presse, 2012

About the Author

Agence France-Presse

Copyright Agence France-Presse, 2002-2025. AFP text, photos, graphics and logos shall not be reproduced, published, broadcast, rewritten for broadcast or publication or redistributed directly or indirectly in any medium. AFP shall not be held liable for any delays, inaccuracies, errors or omissions in any AFP content, or for any actions taken in consequence.