Are Your Lean Leaders Getting the Right Training?

It is an unfortunate fact: Many senior leaders and senior staff do not understand the fundamentals of lean. It’s one thing to recite knowledge of lean, and another to live lean every day—both on the floor and in the executive suite.

In a recent survey we conducted on “Why Lean Fails?” companies from around the world reported the No. 1 reason for their lean efforts failing was “no leadership.” Breaking that down further, the key causes of no leadership were a lack of understanding of lean (i.e., poor or nonexistent leadership training) and a lack of engagement.

Lean leadership training is critical to an organization’s forward movement. It provides executives and managers with basic knowledge of the language, philosophy and concepts of lean. A well-designed and -delivered lean leadership training program provides leaders with essential tools like team-based problem-solving that they need to solve the problems they face. They have the knowledge to ask the right questions and redirect the course of projects that run into rough waters.

To be truly effective, lean leadership training must be well-designed for your organization and delivered by someone who understands the organization. Here is how to get the most out of your company’s lean leadership training.

Step 1: Decide whether you need lean leadership training in the first place.

Let’s look at topics that leaders of top-performing organizations have addressed in their efforts to define what they need from their lean training programs:

- How well does your leadership team understand and use lean tools to solve the issues and problems they face?

- Is the team communicating effectively across all levels of the organization?

- Is leadership working with employee teams to prioritize, implement, and monitor improvement activities and change course as needed?

- Are improvements efforts aligned with the company’s business goals?

- Do your management teams use the same standard operating practices across all locations?

One of our clients hired a new vice president for manufacturing. Having witnessed the benefits of his previous company’s lean efforts, he saw an opportunity to provide managers across his new employer’s plants with lean continuous improvement knowledge, tools and improvement strategies. The VP advocated for a training program that would help these plant managers talk the same language, better coordinate their improvement efforts, and apply lessons learned across plants.

Step 2: Tie the training into your organization’s need to improve.

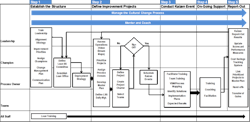

Every organization needs to improve, and most have active improvement efforts—either lean or meeting ISO/industry standards. Many organizations have created plans. Figure 1 shows an example of a lean implementation roadmap.

Figure 1. Example of a Lean Implementation Roadmap (Daniel Penn Associates)

By pinpointing unresolved issues that constantly hold back the organization and how they can be improved through lean, you can confidently supply the “whys” for any skeptics of proposed lean leadership training.

We have found that incorporating discussion of the company’s lean roadmap – whatever stage of progress it is in – is an effective way to demonstrate the use of lean concepts. This is crucial to help reduce resistance, spread the right learning and engender the type of commitment necessary for a lean program.

Step 3: Get your CEO (or site executive) on board.

Crucial to success of training is getting leaders to think about change management as part of the lean roadmap. The CEO communicates why and how the lean leadership training will take place, and what outcomes are expected.

During a recent training, a company’s CEO visibly demonstrated her support to the leadership team. She communicated expectations in advance. She kicked off the training with an in-person presentation. She thanked her team after the event. Post-event, she encouraged follow-up meetings that would help the team apply the concepts they learned to build upon the company’s lean roadmap.

Step 4: Pick the right outside facilitator who brings experience, perspective, balance, and objectivity to the training.

The facilitator you choose doesn’t need to understand every detail of your business, but they need to understand how you operate and what challenges you want to solve. They will have experience in implementing lean. They will have faced the same challenges as your leadership team has. Do they have skills in designing lean improvement events and training leaders in multiple roles within diverse organizations, including companies of your size and type? Are they willing to collaborate with you to tailor their training materials to meet your needs?

Step 5: Design the training.

Work closely with your facilitator to create a program that meets your lean leadership objectives. The best training programs are highly interactive and encourage group problem-solving (a cornerstone of Lean).

The training should be mandatory for everyone on the leadership team, including the CEO, executive leadership, site managers and their direct reports. Ideally, the team will meet offsite – away from distractions that may pull participants back into the facility.

Here's an outline for a two-day lean leadership training we recently presented:

DAY ONE

1. Introductions

2. Lean overview

- What is lean?

- Elimination of waste

- Understanding the value stream

- Where does lean apply in our business?

3. Value-stream mapping

- Company’s current state map

- Company’s future state map

4. Lean Tools

- Workplace organization – 5S

- Process focus--workflow, cells kanban

- Poke yoke mistake-proofing

- SMED set-up reduction

DAY TWO

4. Lean tools, continued

- Predictability and consistency--standard work, problem-solving, application exercise

- Total productive maintenance (TPM)

5. Kaizen

- Continuous improvement

- Kaizen events

6. Lean Management Concepts

- Lean daily management--organizing for lean (tiers and escalation)

- Visual factory

- Change management

- Communication

- Develop an elevator speech

- Lean road map

7. Where does [Company] go from here?

- Discussion of next steps

- Create a lean roadmap (or work from an existing roadmap) – focusing on the processes most critical to the company’s success.

The training should include exercises that reinforce main lessons. The exercises may be conducted on the floor or in the classroom.

Step 6: Recognize and Reward.

Recognize the leadership team for going through the training and using the tools. Communicate their participation throughout the organization. Prepare certificates of completion for participants that are signed and delivered by the CEO. One of our recent customers ordered jackets imprinted with the company’s logo and their lean seal for each participant. Ongoing encouragement in the form of emails, company newsletter articles and recognition at company-wide events will reinforce a lean mindset across the organization.

Step 7: Post-Training: Now What?

After the training, the leadership team needs to hold each other accountable to “walk the walk” and “talk the talk” on lean.

They can:

- Use the monthly leadership meetings to discuss what each member of the leadership team is doing with lean – both themselves and their teams.

- Get feedback from employees through 360-degree reviews or employee surveys.

- Audit each other’s operations/departments.

Lean leadership training is an important first step to achieving a lean culture – where all employees are engaged and play a role in creating the best products and services for your customers.

Mike Beauregard is an international consultant and Tony Rodriguez is president at Daniel Penn Associates.

About the Author

Mike Beauregard

Senior Consultant, Daniel Penn Associates

Mike Beauregard is a senior consultant with Daniel Penn Associates. He is an international consultant and lecturer on the application of lean manufacturing and quality improvement techniques to manufacturing, warehousing, and distribution operations. He has held engineering, manufacturing, and plant management positions in the discrete parts manufacturing, plastics and chemical process industries. Mike is a registered professional engineer and a certified quality engineer. He is a ninth-time member of the Board of Examiners for the Malcolm Baldridge National Quality Award and served in two Connecticut quality awards as a senior examiner, team leader and instructor.