You've Got an Urgent Business Case for Lean. Now What?

In today’s era of relentless disruption, businesses are seeking ways to step up the pace of improvement. While lean manufacturing has revolutionized efficiency, cost-cutting and quality, the new business paradigm demands a faster approach. This is where rapid deployment comes into the picture.

Case Study – Verde Valle

Verde Valle is a food company producing rice, beans and cereals, among other products. The urgent concern of the management team was falling behind in fulfilling the growth in orders because their capacity was limited. There were two options to increase capacity: invest in more equipment, space and hiring or implement process improvements. They chose lean and the clear objective to deliver growth with existing resources.

The Pillars of Rapid Deployment

The cornerstone of rapid deployment is significant improvements within six months by mobilizing people as an army of creative problem solvers to resolve one to two critical issues. At its core lies an urgent business case and a deeply rooted conviction for employee engagement.

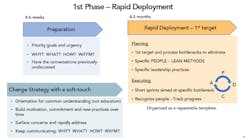

Preparation

The initial phase lays the groundwork by establishing and broadly communicating the “Why” and “What” of the business case. An open discussion framed as ‘What's In It For Me?’ (WIFFIM) cultivates enthusiasm and individual investment in the project. Proactive measures are taken to address questions and uncertainties with the understanding that change brings both excitement and anxiety.

Planning

This phase adopts a targeted approach, focusing on a key strategic objective. The approach is to divide and conquer by breaking down the problem area into smaller, solvable pieces. This plan pinpoints those specific bottlenecks and areas of waste and carefully selects those specific employees who will be most instrumental in achieving the target. They are then equipped with relevant lean tools and methods.

Execution

Over four to six months, the action is iterative problem-solving. Each bottleneck is addressed in rapid cycles. This establishes a consistent rhythm of improvement that builds momentum and drives the effort forward. New information and insights are uncovered; the approach is refined. Contributions are acknowledged and progress is tracked.

Expansion

Planning and execution develop a culture of rapid action through employee engagement. We then begin to amplify the principles, processes and culture throughout the company, expanding to new targets and additional business areas. Preparation, planning and execution phases become a proven, repeatable template. In short, the expansion phase involves scaling up.

Share Your Opinions on Manufacturing Technology

IndustryWeek is in the midst of our annual technology survey. We'd love to hear your thoughts on how well technology suppliers are supporting manufacturing and what's working (and not working) with your tech investments. People who complete the survey will enter a drawing for one of two $50 Amazon gift cards. Please take some time and share your thoughts.

Planning established the initial scope as a small business unit. The operations director became the prominent leader during the implementation. The operations director led the cross-functional implementation team of operators, quality inspectors, leaders from sales, operations, quality, maintenance, logistics and finance. Specific target milestones were developed. Business leaders and the implementation team were trained in the lean philosophy, methodology and specific tool of Value Stream Mapping to identify bottlenecks and significant wastes. They developed a future value stream map to increase capacity 60% over the next six months and an implementation plan to remove bottlenecks on a two-week cycle.

The key bottlenecks were equipment change-over time, unplanned downtime, wait time on material and quality defects. Execution started with the basics of 5S housekeeping, standardized work and visual management. Every morning at the beginning of the shift, the implementation team had a five-minute meeting on the production floor to define production targets of the day. During the day, operators started measuring every step of the production line using an internet of things device and calculated each day the overall equipment effectiveness. Then, at the end of the day, the team had a final five-minute meeting to evaluate the results of the day and understand the main causes of problems.

Then the top bottleneck for each step in the flow was addressed. This demonstrated capacity was improving within 3 months. Improvement cycles then addressed the next set of bottlenecks through the entire flow, thus achieving the next set of milestones.

The main tools implemented to increase capacity were quick change-over preparation, total productive maintenance, kanban, error-proofing and cross-training.

The results were remarkable: an increase of almost 40% in revenue and a 15% reduction in conversion costs. In the beginning, not all were convinced. Some opposed the initiative, but resistance to change decreased with the significant results.

The expansion built upon the large victories from the previous stage and focused on increasing capacity in other business lines and integrating lean into other functions like sales, logistics and product development. Continuous improvement never ends; therefore Verde Valle is always executing improvement cycles with value to the customer, company and employee always in mind.

Takeaway: Time to Reimagine Lean

Rapid deployment offers a revitalized lean methodology, aligned with today’s fast-paced business landscape. To unlock its full potential, it is crucial to reimagine lean as an approach for swift sustained gains in productivity, profitability and competitiveness. Isn’t it time you gave lean a fresh look?

About the Author

Luis Socconini

Director, Lean Six Sigma Institute

Based in the San Diego area, Luis Socconini is co-founder and general director of the Lean Six Sigma Institute with a presence in the U.S., Europe, Latin American and Africa. With over two decades of experience, LSSI has equipped over 70,000 professionals with the knowledge and skills to drive process excellence and achieve tangible results. World-wide programs helped over 400 organizations become lean enterprises, leading to impressive cost savings of over $500 million. He is a distinguished lecturer at universities, conference speaker and author.