Is Lean a Waste Elimination Program or Striving for Excellence?

In the 1990s while first learning about Japanese manufacturing and Toyota, I was also studying organizational development. A retired University of Michigan researcher, Lawrence Lippitt, ran a monthly training course based on the starting point of preferred futuring. He explained that they discovered the methodology in the 1960s when a national organization was trying to improve race relations. Mixed race groups would discuss the problems leading to racism and the discussions were taped. They noticed when they studied the tapes that the energy level of the group went down lower and lower as the discussion continued.

They got a brainstorm to try a different approach, this time focusing on the group building a positive vision for the future of race relations in the U.S., and lo and behold the energy increased as the discussion continued. They found a key to individual and group psychology: Focusing on problems in the current state drains our energy, while building a positive future vision to strive for builds positive energy for change.

This has been the basis for many approaches to organizational development, which includes three aspects:

- Understanding the current state,

- Developing a desired future state, and

- Developing an action plan to get to the future state.

Thinking around lean is going through a metamorphous that builds on that fundamental insight. As we know Toyota is the original model for lean and there have been many interpretations (and misinterpretations) of what Toyota does to be excellent. In Toyota Kata author Mike Rother has a different interpretation than many lean programs that view their goal as waste elimination. In fact it is consistent with my work on lean leadership, but goes farther in creating a defined methodology that can be learned in steps.

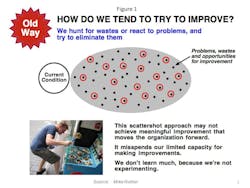

The starting point is the observation that chasing waste is a losing proposition (Figure 1). Like the game of Whack-A-Mole, waste pops up as quickly as you can eliminate it. Think about what we mean by waste—operations overproducing because they are not connected directly to their customer, excess inventory because we are not producing to the customer demand rate, rework because work is not done right the first time, people waiting because of lack of materials, information, or machines shut down, extra motion because standardized work is missing, outdated, incorrect, or not being followed.

Operations that are not operating at a high level of lean typically are lacking underlying process discipline, which leads to these problems and they proliferate daily as the company is in a constant firefighting mode. Trying to eliminate waste in the current system and culture is like identifying and fighting problems—it is debilitating and a losing proposition.

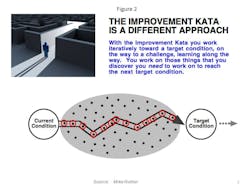

What does it look like to strive for a positive vision? It looks like having a vision, a clearly defined challenge that people rally around, and then targeted improvement to work toward clear, concrete targets (Figure 2). The elements are like those of preferred futuring: What is the condition we are trying to achieve (called a “target condition”)?

What the improvement kata adds that is often missing from process improvement efforts based on visions and action plans is a deliberate process of experimentation and a structure for learning the process of improving. The term kata is often used in the martial arts and refers to a routine which we can practice so it becomes a habit. The improvement kata breaks down process into elemental steps that are practiced repeatedly, with a coach, to work toward the target condition. In this sense it uses the best we know about developing any complex skill—whether in the arts, music, sports, or science. Notice in Figure 2 three key points:

1) The path from the current condition to the desired target is not known in advance. There is uncertainty and the only way to solve this problem is to try things that we believe may move us toward the target.

2) Also note that the path from the current condition to the target is not linear. If we truly do not know in advance, then we are likely to be wrong sometimes and fail.

3) The journey takes place within a defined corridor focused on the objective. Most of the waste that exists in the organization is intentionally ignored, like blinders on a horse. We focus on a specific target with a specific purpose in mind.

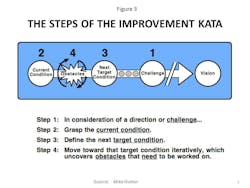

The steps of the improvement kata are always the same, regardless of the level of the problem (whole system or individual process), the particular industry, or the specific strategy of the company. If growing sales is an issue, that can be a focus. If quality is an issue, define a quality strategy. If customer responsiveness is an issue because of long lead times, that can be a focus. It applies to repetitive manufactured and engineered to order one-off products. The improvement process is always the same, even though the problems addressed can vary wildly.

The steps in Figure 3 at a high level are followed: In consideration of a direction or challenge, we grasp the current condition, define the next target condition, and move toward the target, iteratively learning as we go. When a target condition is met we understand much more and are in a position to identify the next target condition. It is seldom the case that we can achieve the challenge with a single target condition. Examples of target conditions could include building every major product type within a single day, product designs that have been thoroughly tested to avoid rework, proactive sales of the product to increase the take rate, building product to the customer demand rate with no defects.

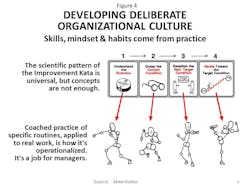

The pattern of the improvement kata is clearly defined, and follows the scientific process that has worked for thousands of years, but simply understanding the steps is far from enough (Figure 4).

The real challenge is to replace the old habits of people that focus on today’s problems, quick resolution, with little learning with a set of skilled routines to systematically improve toward clear targets. This must be learned by managers, supervisors and team members. Experts can act as teachers but the daily coaching and improvement must take place within the established management hierarchy as a part of the daily routine. In this way we replace random waste hunts with striving for excellence.

_______________________________________

Liker Leadership Institute (LLI) offers an innovative way to learn the secrets of lean leadership through an online education model that is itself lean, and extends that lean education far beyond the course materials. Learn more about LLI's green belt and yellow belt courses in “The Toyota Way to Lean Leadership” and “Principles of Lean Thinking” at the IndustryWeek Store.

About the Author

Jeffrey Liker Blog

CEO

Dr. Jeffrey K. Liker is Professor of Industrial and Operations Engineering at the University of Michigan and a professional speaker and advisor through his company Liker Lean Advisors (LLI), an organization established with a network of associates to teach and consult in the Toyota Way. He is also CEO of Lean Leadership Institute, the home for online courses beginning with The Toyota Way to Lean Leadership.

Dr. Liker is author of the international best-seller, The Toyota Way: 14 Management Principles from the World's Greatest Manufacturer (McGraw Hill, 2004), which speaks to the underlying philosophy and principles that drive Toyota's quality and efficiency-obsessed culture. The companion (with David Meier) Toyota Way Fieldbook (McGraw Hill, 2005) details how companies can learn from the Toyota Way principles. His book with Jim Morgan, The Toyota Product Development System (Productivity Press, 2006), is the first that details the product development side of Toyota. His articles and books have won nine Shingo Prizes for Research Excellence and The Toyota Way also won the 2005 Institute of Industrial Engineers Book of the Year Award and 2007 Sloan Industry Studies Book of the Year. In 2012 he was inducted into the Association of Manufacturing Excellence Hall of Fame. He is a frequent keynote speaker and consultant.