A Nearshoring Checklist: 4 Prerequisites for Success

Global manufacturers are increasingly turning to regionalization to boost supply chain and manufacturing resiliency, speed time-to-market and reap other business and environmental benefits from reshoring part of their operations to be closer to the markets they serve. A recent example is Enphase Energy, a Flex customer who recently announced the first shipments of microinverters for solar energy systems from our factory in Timisoara, Romania. This strategic decision enabled Enphase to improve delivery times to its customers in Europe.

This isn’t an isolated incident. Regionalization has become a widespread trend. In a 2022 McKinsey & Company survey of 113 supply chain leaders worldwide, 44% of respondents, up from 25% percent the previous year, stated that they were developing regionalized supply networks.

However, successful regionalization requires careful planning and a clear understanding of four core prerequisites:

Footprint/capacity: the existing manufacturing ecosystem and facilities in-region

Supply chain: the process for sourcing materials and shipping products

Technology: the advanced manufacturing technologies and technical expertise available in-region

Talent: the workforce needed to support operations within the regional manufacturing node

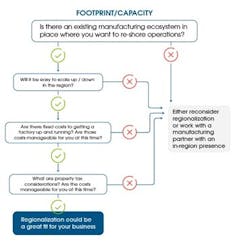

Footprint/Capacity

First, companies must assess whether they have an existing footprint in-region, and whether they currently have the capacity to support moving part of their operations to a location. For example, a company might already have a factory in North America that is dedicated to manufacturing a specific product line. Beyond the space considerations of adding additional factory lines, leadership must also determine whether the factory is equipped with the machinery and resources to support the product line they plan on reshoring.

If the current space isn’t sufficient or if a company doesn’t have any existing footprint in-region, it will have to weigh the cost of building out additional facilities against the benefits of regionalization. In some cases, it might be cost-effective to find a manufacturing partner with the capacity in-region to support operations for the re-shored product line.

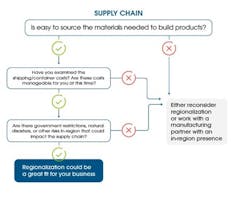

Supply Chain

Part of the cost/benefit analysis for companies considering regionalization is also understanding how the reshored manufacturing site would interact with other parts of the value chain. Would it be easier or more difficult to access raw materials? Would it be faster, more reliable, or more sustainable to fulfill orders and get them into customers’ hands once the products have been built? Having a strong supplier network in-region that is transparent, collaborative and responsive is crucial.

Technology

Implementing advanced manufacturing technologies like automation, simulation, additive manufacturing and digitization introduces greater efficiencies into the manufacturing process. And tying back to the footprint/capacity considerations, these technologies can also lead to space and materials savings. For example, companies can invest in a single piece of equipment that serves multiple functions or rely on digital twins and simulation rather than building physical prototypes.

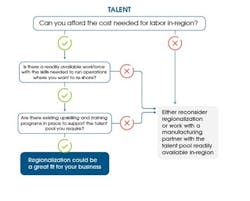

Talent

Of course, companies cannot simply build a factory in-region and fill it with equipment without a plan in place for staffing. Without a dedicated workforce to run operations, the entire plan falls apart. And companies need to look beyond hiring for numbers—they need to consider the expertise and talent available in-region.

If regional manufacturing sites are outfitted with advanced manufacturing capabilities, they will need a workforce with technical expertise to keep operations running smoothly. Flex has implemented the Capability Acceleration Program to train employees around the world in a broad range of disciplines, including automation, simulation for future stage modeling, extended reality, and more. At our site in Althofen, Austria, we established an “IIoT Academy” and partnered with universities to upskill workers.

Regionalization = a Multi-Dimensional Equation

Regionalization is a strategy that benefits many companies, promising greater resiliency, efficiency and even sustainability. Thinking about regionalization through the lens of the four prerequisites I laid out – footprint/capacity, supply chain, technology, and talent – can ensure that companies reap the full benefits of their reshoring efforts.

Hooi Tan is president, global operations and supply chain, at Flex.

***To comment on this article, please scroll down past story recommendations to "Voice Your Opinion."