The 2025 U.S. Open delivered a master class for golfers and procurement leaders alike. When thunderstorms on June 15 transformed golf's most demanding major into what many called "unplayable", J.J. Spaun didn't just survive—he thrived. While seasoned champions faltered in the chaos, Spaun seized his moment with a simple philosophy: "Perseverance… I've always battled through whatever it may be to get to where I needed to be."

His victory wasn't luck. It was strategic adaptation to seize the opportunity at the most difficult moment.

Procurement’s Own Perfect Storm

Today's procurement leaders face their own impossible conditions. After a crushing 28% cumulative cost surge from 2020 to 2024 (U.S. BLS Producer Price Index), businesses now navigate U.S. tariffs, trade volatility and unprecedented margin pressures. Yet 74% of executive leaders are placing even greater emphasis on cost optimization today than in 2024 (Gartner).

Like Spaun standing over that final putt in driving rain, procurement's defining moment is here. Spaun secured his victory with a remarkable 64-foot birdie putt; can procurement strategically adapt and emerge as a champion?

The Brutal Reality: Traditional Playbooks Are Failing

Consider this devastating scenario a client experienced that's playing out across industries.

A U.S. component manufacturer, reputable for technology leadership and quality, had maximized profit margins for years through aggressive material cost reduction and lean management. Then the market changed. Competition intensified. A top customer demanded a 30% price reduction.

Procurement had no answers. The traditional levers were exhausted. Executives faced an impossible choice: Lose the customer or lose money.

This isn't an outlier. Inflation and tariffs have rewritten the rules. Yesterday's savings were shared with customers; today's supply markets demand year-over-year price increases. Even the much-hyped AI productivity initiatives have delivered disappointing results for immediate cost reduction, with an estimated 75% failing to meet expectations (Gartner).

How Can Procurement Continue to Deliver Value and Drive Savings?

While others chase the latest technology trends, true procurement leaders are embracing a paradigm shift. It's time to move beyond artificial intelligence to authentic intelligence—understanding value from your customers’ perspectives.

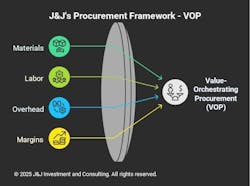

Beyond leveraging AI, I propose a new framework to transform procurement from cost saving to value creation: Value-Orchestrating Procurement (VOP).

The VOP framework assesses total product (service) values from customers’ perspectives, applies systematic supply chain problem-solving to optimize value-added elements and enables profitable revenue growth.

Instead of asking "How can we cut costs?”, VOP asks, "What value are customers actually willing to pay for?" This customer-centric lens reframes how procurement approaches the four pillars of product value: materials, labor, overhead and margins.

VOP in Action: How a Manufacturer Saved Their Business

Let's return to our struggling component manufacturer. Facing that “Mission Impossible” 30% price reduction demand, they implemented VOP with blockbuster results. Key to their success was:

Materials: from specs to value. Moving beyond traditional commercial tactics, procurement leveraged value analysis and value engineering to examine bill of materials through the customer's eyes. Working collaboratively with the customer and suppliers, they identified and eliminated non-value-added materials, features and specifications. Result: 30% material cost reduction with zero performance degradation.

Direct labor: smart manufacturing orchestration. The company had struggled for years to advance smart manufacturing due to capital constraints and technical expertise gaps. VOP repositioned procurement as a strategic orchestrator. Through targeted global sourcing and supplier engagement, the company was able to implement automation solutions swiftly. Result: 50% labor efficiency improvement.

Overhead: process value alignment. Business processes drive overhead cost, but not all processes create value that customers are willing to pay for. Using VOP’s Value-Based Customer Segmentation model, procurement assessed internal processes and procurement requirements with stakeholders. They systematically eliminated activities that existed for internally perceived value rather than customer requirements. Result: 20% overhead cost optimization.

Margins: data-driven validation. Initially skeptical executives questioned the 30% price-reduction demand. After analyzing alternative supply costs and benchmarking competitions, procurement substantiated the threat with market intelligence and drove the implementation of VOP. Result: with materials, labor, and overhead optimized, the company not only survived the price reduction, but actually improved gross margins.

The Paradigm Shift That Changes Everything

VOP is a transformation. It enables business to see through your customers’ eyes, on what materials/labor/overhead/margin they do value.

How to transform? Collaborate. Engineer value with customers and suppliers. Redirect procurement’s mission from cutting costs to fueling growth.

What is your first move toward VOP? Start where Spaun began: embrace the storm.

Pick one product line and ask:

"If our customer could eliminate one specification without losing core functionality, which would they choose?”

“Which activity are we doing that they didn’t ask for?”

“Where does our overhead outpace what they’re willing to pay for?”

Gain momentum on the first product, then scale across the organization to truly orchestrate the total value. Your customers are waiting for the value you can create. The only question is whether you'll seize it.