Sourcing and Product Design Work Better Together

Amid the churn of the pandemic and change on multiple fronts, consumer goods manufacturers now face historic pressures to contain costs, navigate ongoing uncertainty in both supply and demand, and live up to their sustainability pledges—a top mandate. All three challenges require urgent attention and come at a cost. Breaking with traditional sequential processes, we’d like to make the argument for tackling all three challenges at once.

To achieve this, we recommend an elevated, agile and crowd-sourced approach—let’s call it “Design to Value”—that delivers tangible sustainability gains, increased financial impact and enhanced resilience against supply/demand uncertainty.

Here’s the key concept: Traditionally, product design and sourcing have been pursued separately, as sequential activities. First, designers set product and material specs, then procurement sends these out to suppliers for competitive quotes.

Breaking with this conventional approach, we suggest merging product design and sourcing into a single process. This actively engages the supplier ecosystem and helps unlock fresh value in terms of cost reduction, sustainability, secure supply, and brand appeal—all of which become part of the design process itself. Let’s take a look at how we arrived here.

Making a Major Leap

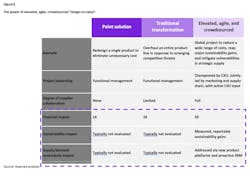

Until now, companies looking to keep pace with fast-moving technologies or changing needs have taken incremental steps toward the approach we’re describing. They sought point solutions to simple problems, such as redesigning a single element to eliminate unnecessary cost. This initiative was left to a project manager, and a successful outcome did not require any special collaboration with suppliers. While the sustainability impact was not evaluated, there was still a financial gain from the undertaking—here we’ll call it a 1x financial impact.

The second step, let’s say a company looking to overhaul an entire product line in response to emerging competitive threats, has been traditional transformation. Once again, functional management would take over the leadership of this type of project, and some limited collaboration with suppliers would be necessary for success. This typically would not involve an evaluation of the sustainability and supply chain impacts; however, the financial impact would be potentially double that of the point solution.

Design to Value is the next step for companies looking to make a major leap forward across their entire global value chain—simultaneously addressing costs reductions, sustainability gains, and supply chain vulnerabilities. As the following figure shows, the potential financial gain is five times that of the point solution, and more than double that of a traditional transformation.

A Collaborative Effort

We describe the model’s objectives as elevated, since this new approach is meant to have a lasting and measurable effect on companies’ top- as well as bottom-line performance, sustainability, brand reputation and operational resilience.

Sustainability efforts need to happen in tandem with supply chain resilience and financial gain. This can only be done with a concerted, collaborative effort from all stakeholders, starting with leadership. The initiative would be sponsored by a company’s customer experience leader and jointly led by the chief marketing officer and chief supply chain officer—all of whom want a positive outcome. A chief sustainability officer should also help shape the program, provide design input and validate the sustainability baseline-to-benefits tracking methodologies. These top leaders, rather than middle management, should personally communicate within the company and to strategic suppliers, ensuring that all program participants feel fully motivated and accountable for success.

This integrative approach needs to take the form of an agile process in which innovative and imperfect ideas are promptly tested with suppliers and consumers—for example, frequent and rapidly repeated scrums to iterate final designs.

Crowd-Sourcing

In contrast to the customary siloed approach to product and package design usually owned by new product development and marketing, we recommend that from day one, sustainability considerations are integrated into a company’s thinking around supply chain resilience. This involves procurement, supply chain leaders, outside product and package design experts, technical services and customer sentiment analysts. From the outset, the role of new suppliers as well as incumbents is critical, as the approach offers them a prominent seat in the product-design process.

Product Teardowns

One way to put this approach to the test is to begin with deconstructing a competitor’s product. This can happen on-site or in the facilities of trusted suppliers. Expert product and package designers should be involved in these sessions in order to blend their deep understanding of design choices with the team’s expertise in production and logistics.

With the aim of gaining insights into competitors’ products and packaging, a teardown surfaces a wide spectrum of potential design changes, from minor tweaks to more aggressive redesigns. For example, if a competitor uses less glass in their packaging, this points to an opportunity to save costs and operate more sustainably.

Teams can be creative and expansive in their search for fresh opportunities—for example, being alert to alternative manufacturing approaches and product platforms, both of which can make the company far more nimble in response to shifts in consumer demand while also lowering costs and/or reducing its carbon footprint. Some ideas may seem impractical at first, but keep track of them all—experience has shown that these kernels can be of great value later on.

In a recent case study concerning a global food business, advanced packaging design capabilities were integrated with the company’s traditional commercial strategies to reduce packaging costs. The company’s European and North American packaging groups identified global best practices and developed more than 125 implementable packaging design ideas. The new concepts reduced costs by 10% to 25% and substantially improved the sustainability of the packaging. The exercise added significant visibility to supplier costs, sparked collaborative ideation with the company’s key packaging partners and empowered the team during supplier negotiations. One tangible innovation outcome in their product and customer delivery mechanisms came by prototyping an IoT-enabled flavor dispenser to replace bulky, costly and material-intensive syrup bottles in coffee shops

A Macro Perspective on Sustainability

The most promising ideas embody the optimal mix of design, sustainable value, consumer sentiment, materials, manufacturing,and logistics expertise ― as well as a macro marketing and operational perspective.

A concurrent approach to sourcing and this collaborative redesign approach allows the procurement function and supplier ecosystem to serve as active partners with marketing in gauging each product and packaging idea. In addition to requesting cost estimates, suppliers are encouraged to actively suggest design improvements, from their perspective, and to highlight any opportunities they see to maximize sustainability benefits.

Sustainability, long an afterthought in product design, is a central consideration when vetting design changes. It will become increasingly important to provide measures of how each design change under consideration would impact water use, energy consumption, and CO2 emissions

Conducting consumer surveys can also add value by offering more objectivity about whether proposed design changes would positively or negatively impact a product’s consumer and sustainability appeal. These analyses can uncover what consumers find unsatisfactory even when offering five-star product ratings, as well as the unnamed satisfiers that can be found in one- and two-star ratings—both valuable and often overlooked insights.

This array of cross-functional, multi-organizational interactions will lock in priority design changes, shapes and scenarios, and will quantify the projected cost and sustainability benefits.

Implementation

With broad potential benefits and relatively easy attainment, this “Design to Value” approach prioritizes implementation and captured value. Financial and sustainability benefits should be tracked with equal rigor, reported in the company’s sustainability reports and, as appropriate, included in consumer communications.

Another benefit to this approach is a fundamental redefinition of the working relationship between sales and marketing, the supply chain organization and the supplier ecosystem. These newly combined strengths in crowd-sourced agile design ideation, consumer sentiment analysi and multi-functional engagement can become a source of competitive differentiation for years to come.

Setting the Climate Change Agenda

Taking a more comprehensive approach and blending diverse internal and external expertise into a single shared pursuit means you’re doing all the things necessary to win in your marketplace, Today, this must include conscientious sustainable action as a corporate imperative. Companies grasping this reality and decisively moving past trade-off thinking into new, intermodal approaches are throwing down the gauntlet to all other companies to address not only company performance and consumer appeal, but the immediate urgency of climate change.

Arun Kochar is a partner in the strategic operations practice of Kearney, a global strategy and management consulting firm, and Greg Portell leads the firm’s global consumer practice. The authors wish to thank Jesse Chafin and Janus Cataluna for their contributions to this article.About the Author

Arun Kochar

Partner, Kearney

Arun Kochar is a partner in the strategic operations and supply chain practice of Kearney, a global management consulting firm.

Arun's experience on a six-month project with a wine industry client in many ways mirrors his trajectory as a consultant at Kearney, where he began as a business analyst in 2004 and worked his way up to partner.

On that project, Arun learned just how intensive wine-making was—from acquiring the grapes to selling the wine derived from those grapes, the entire process could take more than five years.

“The beverage alcohol industry is a relatable yet complicated industry, driven by its multi-tier value chain. That’s why I enjoy it so much,” Arun says. “You talk to everybody, including the brand owners, distributors, retailers—even the farmers supplying grapes and malts. Something that seems quite casual and ordinary—a bottle of wine or whiskey—is actually quite fascinating and involved to make, distribute, and sell.”

Working on such engagements—both short- and long-term—during his tenure at the firm has allowed Arun to develop a unique knowledge of the operations value chain, from planning and procurement to manufacturing, distribution, and customer service. His experience allows him to advise on very specific cost take-out or growth challenges, as well as on large-scale transformations such as mergers and acquisitions integrations.

“Most big transformations fail because people don’t like to change,” Arun says. “We put together a case for change that everybody is energized about."