The commercial aircraft of tomorrow -- or tomorrow's tomorrow -- could be a leisure playground, one in which passengers use virtual reality to sit at a bar or play golf as they sail 30,000 feet above the Earth. Travelers could relax in privacy in seats cocooned from other passengers, blocked from sound and potentially sight from the rest of the cabin.

Charles Champion, executive vice president of engineering for Airbus, and his team of engineers at the French aviation powerhouse have lofty ideas about the future of the industry, a growing one being fueled by the expansion of commercial aviation in Asia. While some, like the virtual reality vision, are upwards of 35 years off, others are already in the development pipeline.

"We are not at all at the end of the story," Champion says. "There's still a great future for aviation."

The commercial aerospace industry is set to soar to new heights during the next few decades on the back of increased air traffic and demand for new aircraft on a global scale. Airbus expects global air traffic to increase 6% by 2031, with airlines taking delivery of 27,350 new commercial aircraft during that time to accommodate the influx of travelers.

See Also: Manufacturing Innovation & Product Development Strategy

As the price of fuel remains high and global consciousness about eco-alternatives becomes more pronounced, aerospace manufacturers will not only work to develop new cost-effective aircraft but also to bring a slice of the green movement to the blue skies above.

The Future is Now

In many ways, the future of the aerospace industry is sneaking onto commercial aircraft today. Take Airbus' A350 XWB, the in-development wide body plane set to enter service in the latter half of 2014. The A350, like its contemporary, the Boeing 787 Dreamliner, is partially comprised of advanced materials (composites), rather than traditional aluminum, making the plane lighter, more fuel efficient and more resistant to corrosion.

"I think the Dreamliner kind of set the stage with more use of advanced composite structures," says Michael Heil, president and CEO of the Ohio Aerospace Institute, who expects composites to become increasingly common on aircraft.

The A350 also employs advancements suggested through biomimicry, or biologically-inspired engineering. The nose of the plane registers wind gusts and adjusts the wings for increased efficiency. This development is modeled after sea birds, which identify wind changes with their beaks and alter the shape of their wings accordingly.

But that's just the beginning.

Future Face of the Industry

New technologies beginning to enter today's planes are well on their way to becoming the future face of the industry.

The biggest difference between the aerospace world of the past and that of the future is the shift of the success paradigm, Champion says. Whereas in the past, an aircraft's performance served as its barometer of success, now that gauge is also tied to environmental concerns. In its design of new planes and components, Airbus not only tries to create the most cost-effective aircraft but also the one that reduces noise, pollution and fuel consumption.

"Clearly, efficiency is driving the market and the ever-increasing cost of fuel, along with environmental concerns over carbon emissions," says Heil. "The best way to reduce carbon emissions is to design and build more efficient airplanes."

He sees that goal being realized through an electric future, one in which electrical systems replace hydraulic ones, where an aircraft is powered, heated and cooled by electric means.

And he's not alone.

Champion's team hopes to develop an intelligent tractor that would aid aircraft in take-off; the tractor would help propel the plane down the runway, enabling the aircraft to start its engines at the last minute. And they want to add electrical engines to the wheels of the plane to power it while it taxis. The idea is to allow planes to carry less fuel, making them lighter and saving money while also reducing emissions.

Bob Witwer, vice president of advanced technology for Honeywell Aerospace (IW 500/37), thinks most of the advances in the aerospace industry will be tied to NextGen air traffic management. As the Federal Aviation Administration reduces gridlock and improves efficiency -- fuel and time -- by switching to a satellite-based air traffic control system from its ground-based system, aerospace manufacturers, too, will find faster and more environmentally-friendly ways to operate and build aircraft.

He envisions a world in which airplanes operate like clockwork, arriving and departing to the minute like trains. Forget sitting on a plane for an hour after leaving the gate in that slow conga dance with other aircraft to the runway.

"They're burning my time while we do this slow creep, burning gas, generating pollution, like cars do when they're stuck in rush hour," Witwer says.

Aerospace's Hybrid Revolution

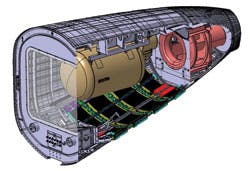

Honeywell -- a New Jersey-based diversified technology and manufacturing company -- is already testing with Safran, a French high-technology company, an electric green taxi system that, like Airbus' plan, involves powering the wheels. Honeywell's system uses the auxiliary power unit generator to provide power to the wheels to allow the aircraft to taxi without using the main engines.

"There are a number of us that believe when you look off into the future, this is something like hybrid cars," Witwer says. "This is an analogous kind of approach. The time is clearly now to move away from inefficient engine power."

Parker Hannifin Corp. (IW 500/92), an Ohio-based diversified manufacturer that provides a number of systems for today's aircraft – everything from flight control systems to engine and fuel systems -- is working with Airbus on the integration of hydrogen-powered fuel cell technology into the electrical system of its aircraft.

"Fuel cell technology exists today and has for many years. Now, we're taking it and transitioning it to an aerospace application," says Mark Czaja, vice president of technology and innovation for Parker Hannifin. "This is not just putting fuel cells on the airplane. It's something you have to be aligned with the aircraft manufacturers on."

Czaga expects to have a flight demonstration program in place by the middle of this decade.

Parker Hannifin is also taking fly-by-wire and power-by-wire to another level. The company is working on embedding more advanced health monitoring into its systems.

While the existing systems already have monitors that indicate when a problem arises, similar to the warning lights in cars, Czaja has his team working on a more advanced system. Rather than just identifying a black and white problem, the monitors would provide shades of preventive knowledge.

For example, instead of a indicating when a system is down, the monitoring devices would indicate when there's a variation in the vibration of a pump, which could be an early indicator of a system failure.

Government vs. Commercial Markets

As technology evolves, so too does the means by which those developments make it into the marketplace.

Parker Hannifin's research and development efforts over the past decade have shifted from catering to the U.S. Department of Defense to focusing more on commercial aerospace.

"In general, you would develop and introduce a new technology on a military aircraft before you would see it migrating into the commercial space," Czaga says. "Our R&D portfolio now has been rebalanced."

That's because there has been less defense spending and more demand on the commercial side. Asia-Pacific airlines alone are forecast to buy nearly 10,000 new passenger and cargo aircraft -- a $1.6 trillion value -- in the next 20 years, which only represents 35% of all new aircraft deliveries for that time period, according to Airbus.

"On the commercial side, there's good growth. That side looks very healthy. The area I'm most concerned about is the military side," OAI's Heil says.

He's worried that with continued DOD funding cuts, research -- a discretionary expense -- will suffer.

"If you cut it, you don't feel the effects until years later," Heil says.

The future success of the industry will depend on manufacturers taking the innovation reins and continuing the development of new technology.

"The good news is if [companies] are successful on the commercial side, they can reinvest some of their profits there into the research side…The leadership of the companies will have to take a long-term view and will have to invest company money in helping make sure they stay technologically ahead of their competitors."

Winovation

To address innovation competitiveness, Parker Hannifin has a formal innovation program, Winovation.

"Parker's innovation initiative, Winovation, has raised the bar in developing 'new-to-the-world, new-to-the-market' products and systems that help increase our customer's productivity and profitability," says Donald E. Washkewicz, chairman of the board and CEO of Parker Hannifin. "Our ongoing investments in these innovative ideas during the past number of years are beginning to bear fruit across our technology platforms and drive growth."

An offshoot of the move away from military R&D is that more doors of entry are opening for introducing new technology.

"A lot of new technological breakthroughs are not only not necessarily coming out of the military, they're not even coming out of the high-end air transport systems," Honeywell's Witwer says. "They're coming through the lower end of aviation, generation aviation or business aviation."

Pipeline of Dreams

The key to developing all of these technologies is in making sure manufacturers and suppliers are on the same page so that the technologies being honed are ones in demand by aircraft manufacturers like Airbus.

"It's really a mixture of vision and preparation of potential product decisions," Airbus' Champion says.

Airbus regularly meets with its Tier 1 suppliers to determine what technologies are in the pipeline and to share its own vision for future advancements. But the perfect marriage between manufacturer and supplier comes when new products are at technology readiness level six -- the highest level of readiness -- when they need them.

Honeywell's Witwer says the development game isn't as risky as it seems because issues like reducing operating costs and emissions and improving timeliness are "immutable values."

"Our environment doesn't change rapidly," he said.

About the Author

Ginger Christ

Ginger Christ, Associate Editor

Ginger Christ is a former associate editor for EHS Today, a Penton publication.

She has covered business news for the past seven years, working at daily and weekly newspapers and magazines in Ohio, including the Dayton Business Journal and Crain's Cleveland Business.

Most recently, she covered transportation and leadership for IndustryWeek, a sister publication to EHS Today.

She holds a bachelor of arts in English and in Film Studies from the University of Pittsburgh.