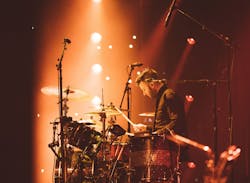

Don't Panic! 3D Printing Lets Drummer March to New Beat

Like many musicians, Dan Pawlovich from Panic! at the Disco has always searched for ways to create new sounds with his instrument. Specifically, he was looking to make a drum resonate better with the lugs actually part of the drum.

A traditional drum has a wooden or metal shell with metal rims and fasteners that attach the drum head onto the shell. According to Pawlovich, a lone drum shell produces a clear resonate note when tapped softly. However, after attaching metal parts to the shell, drummers lose the precision of the fundamental pitch. For decades, drum manufacturers have produced euphonious drums with traditional hardware. However, Pawlovich saw the potential to produce something that could resonate more freely. By designing a drum with the traditionally metal lugs incorporated into the drum shell, he could eliminate some of the external hardware inhibiting the drum’s musical clarity.

“It was intriguing, but there was literally no way for me to know what the thing was going to sound like,” he says. “With a musical instrument, even minor defects can really kind of have an impact on the overall effectiveness of the end product. The beauty of 3d printing is that pretty much everything can exist in the digital domain, until it's time to actually hit the print button.”

Pawlovich spent about three and a half years working with a CAD designer fleshing out the idea before printing this first drum. “I knew the drum had to be a specific size, down to less than a millimeter. We did not stop designing until I knew for a fact that every single measurement in that CAD file checked,” he says.

Hitting print

Once Pawlovich had a design he was comfortable with, he approached Stratasys Direct Manufacturing to turn his idea into a reality. After listening to Pawlovich’s goals and concerns, Stratasys Direct Manufacturing recommended laser sintering technology. Laser sintering builds directly from 3D CAD data via a CO2 laser that fuses powdered thermoplastics layer by layer. Like other 3D printing technologies, it enables part consolidation and complex geometries with the added advantage of no support structures. Parts are printed in a bed of self-supporting powder, with the excess powder easily shaken out during post-processing.

The next step was to find a material that would match well with some of Pawlovich’s needs including rigidity and environmental stability. He needed to avoid a lot of swelling in the heat or shrinking in colder environments. The decisions was made to use Nylon 12GF material as well as a proprietary dyeing process called ColorTek to produce a bright red drum shell. The result: a great prototype that Pawlovich ended up touring with for the next two years.

“It was certainly a great learning experience for us. It emphasized how important the customer relationship is being able to work one on one. There are a lot of different things you can do with additive technologies,” says Statasys Direct Manufacturing’s Lewis Simms. “It is often a matter of engaging with an engineer to figure out how to improve your product further. 3d printing much like any other manufacturing isn't an all or nothing approach. By leveraging the different tools in your tool belt, including different printer methodologies and material options its possible to realize drastically different results.”

Using the same exact file, yet different print methods and materials, Pawlovich now has four drums. Each produces drastically different sounds – at least to a drummer’s ear. “We started with a drum that looks like a traditional drum. We wanted to show that we could do it, and that it could play right next to any traditional drum ,” he says. “We've proven that.”

Pawlovich tells IndustryWeek, looking forward, the goal is to continue to grow and refine the idea.

His advice to others with a product idea? “Start with research and then have fun. This whole thing just started from an idea I had in my head,” he says. “Whether it's 3D printing or any other avenue, keep expanding your borders, look for more and dig deep. Read everything you can, watch everything you can, learn from people who have been there before and who are pioneering things now. Before you know it you might be pioneering something you didn't even realize was possible.”

About the Author

Peter Fretty

Technology Editor

As a highly experienced journalist, Peter Fretty regularly covers advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.