Desktop Health Hears Opportunity to Expand Bioprinting

Desktop Health, a healthcare business within Desktop Metal Inc., is adding PhonoGraft platform to its technology portfolio.

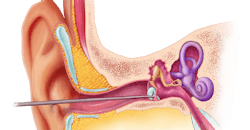

This announcement is a promising direction for Desktop Health with the potential to impact the lives of millions of patients suffering with eardrum perforation, Nicole Black, PhD, vice president of biomaterials and innovation at Desktop Health, tells IndustryWeek. “The PhonoGraft technology aims to support the regeneration of damaged eardrum tissue by incorporating a biomimetic architecture with a biodegradable material,” says Black. “Desktop Health is a visionary company that is imagining how we can design better implants and devices that integrate with the body’s healing processes.”

“We believe that this platform may one day offer a groundbreaking solution to the millions of patients impacted by tympanic membrane perforation (TMP),” said Michael Jafar, president and CEO of Desktop Health.

Pioneering Breakthrough in 3D Printing Biomimicry

The concept for the PhonoGraft device arose after the 2013 Boston Marathon bombings, when many individuals sustained eardrum perforations due to the blast injury. Black, then a doctoral student in Lewis’ Harvard lab, recognized an opportunity to explore ways in which 3D printing might be used to improve outcomes following eardrum reconstruction. Lewis and her research group, in collaboration with ear surgeons Dr. Aaron Remenschneider and Dr. Elliott Kozin from Mass Eye and Ear, assembled a multidisciplinary team of material scientists and otolaryngologists.

Six years of research and development, with an infusion of focused translational funding from the Wyss Institute, led to the creation and preclinical de-risking of the PhonoGraft material and device platform. Black became an entrepreneurial champion for the technology; she and several colleagues founded a startup, Beacon Bio, to advance the technology into commercial development. Beacon has now been acquired by Desktop Metal.

“This device, which is manufactured from a biodegradable elastomer in the form of customizable biomimetic circular and radial scaffolds, is intended to function like the native eardrum. Preliminary bench studies show that the PhonoGraft device not only closed the eardrum perforation; it supported the body’s regeneration of the complex eardrum structure,” said Black, in a statement. “Such graft architectures benefit from the use of 3D printing and permit the eardrum to transmit both low- and high-frequency sound waves.”

“We foresee PhonoGraft technology evolving to tackle other problems with soft tissues across the body. Specifically, we are exploring ways the PhonoGraft material might be useful for reconstructing other tissues whose structure is important to their function,” says Black. Additionally, we hope to design grafts for future markets where patient anatomy could play a role in the function of tissue grafts.”

PhonoGraft technology is in advanced-stage research and development, and not available for sale anywhere in the world. Black and her team at Desktop Health intend to conduct additional preclinical studies and pursue FDA review.

“To be on the forefront of biofabrication and 3D printed medical device solutions, we recognize there is a lot of work to do on the regulatory front as well as scaling up manufacturing,” says Black. “Our current focus is on the advanced research and development of PhonoGraft device and, in tandem, beginning to explore how this technology might be used for additional soft tissue regeneration for other healthcare applications.”

About the Author

Peter Fretty

Technology Editor

As a highly experienced journalist, Peter Fretty regularly covers advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.