Fifty years ago, Jeff Carr was working at IBM's New York headquarters, helping to develop the early ancestors of today's critical manufacturing software, the sparks that would ignite today's digital industrial revolution. One of these projects was the first Material Requirements Planning system for an equipment manufacturer. Instead of pen and paper, planning and scheduling could be done electronically. Over the decades this morphed into Enterprise Resource Planning, or ERP, software.

Carr believed that despite IBM creating the marketplace, it would not succeed in its MRP strategy, but he thought he could. He started his manufacturing software company in 1975, which flourished in the 1980s. After selling the company in the 1990s, he formed Ultra Consultants, which specializes in advising manufacturers and distributors on how to get the most out of their ERPs.

Basically, ERPs centralize all the critical data manufacturers need, from supply chain to financials to operations, distilling these numbers into understandable reports and real-time dashboards, empowering management to make better decisions. Ever since the Industrial Internet of Things came around, the flow of data, and the importance of leveraging that data, has never been more critical. But getting IT and OT aboard, finding the financial and human capital, and coming up with a solid game plan are just a few reasons the C-Suite may put off getting or changing an ERP solution.

"Most CEOs don’t want to do an ERP project," says Carr, who has worked with more than 1,000 manufacturing and distribution companies. "They don’t want to get anywhere near it because everybody keeps talking about how difficult it is."

Carr, Ultra's CEO for the last 25 years, blames bad press. And it’s true Avon Products outright abandoned its $125 million ERP from SAP in 2013, but six years in technology is like four product lifetimes. Carr says vendors have made things easier, and companies have learned from their mistakes. He believed ERP failure was a myth.

So the ERP consultant with half a century of experience called in a colleague with about 45 years under her belt: Cindy Jutras, president and founder of research and advisory firm Mint Jutras. She has worked with ERPs for more than 30 years.

Together they have about a century of experience, and together, with all that wisdom and IT knowledge, they were determined to get to the truth.

The Survey Says

Mint Jutras sent out a survey last November to a paid research panel of 315 respondents, all in leadership roles at manufacturers and distributors that exceed $25 million in annual revenue, and all of whom have deployed an ERP.

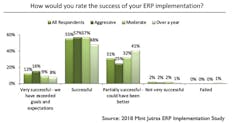

The key findings of the survey, called "The Real Facts about ERP Implementation," was that two-thirds of respondents graded their ERP implementation as "successful" or "very successful." The survey found 31% thought their ERP project was at least a partial success, while 2% thought they were "not very successful." Only one out of 315 thought their ERP deployment was a failure.

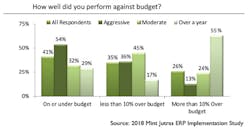

Pushing for quicker completion time also paid off, as 54% of "aggressive" companies, those who expected a "go live" date within six months, reported coming in at or under budget, while 13% were at least over budget. Also, 57% of aggressive businesses achieved ROI on time or earlier than expected.

Conversely, 55% of those who planned on taking more than a year came in higher than 10% over budget, while 29% were on or under budget. One in three are still waiting for that ROI, while 27% obtained in in expected time and 6% earlier.

Overall, Jutras was not surprised by the low amount of negative feedback, though she says the rating of "very successful" was thrown around a bit cavalierly.

"I honestly believe that many of these people are overestimating their success, and they are not as successful as they could be," Jutras says, "because they are leaving some of those benefits on the table."

The top three benefits respondents checked where ERP produced ROI include: reduced IT costs (40%); reduced inventory levels (38%) and reduced cycle time (35%). They could pick more than one.

"What troubles me is people aren’t going after all of these," Jutras says. "Tell me a manufacturer who couldn’t stand to improve their inventory, whether that's regarding levels or accuracy?"

To me that should be number one in everybody's mind and only 38% did it," she continues. "The only place where I walked into and it had 100% inventory accuracy was a bank!"

Companies simply don’t gather enough metrics to start with, and sometimes don’t even know that they should.

"If you don’t measure it, you don’t manage it," Jutras offers.

Changing Expectations

Advising executives on the importance of data is like lecturing an Italian grandmother on cooking with garlic and basil. They know darn well how important they are, just not all of them use it in the right amounts (ed. note: Mine did).

As with everything in manufacturing technology, it's a never-ending education, one that by the share of ERP success, is something for the industry to be proud of.

"They've learned a lot, and they’re doing better with the overall implantation of the budget on time," Carr says. "There's still a reluctance to spend a lot of money on driving improvements."

And that's dulling your sharpest new productivity tool.

"I don’t think CEOs totally understand how much money they could be saving, how much return they could be getting on their investment if they drive a little bit harder," Carr says.

And what is manufacturing without driving improvements? Kaizen. Six Sigma. Lean. TPS. It's all about getting better, a way of searching the factory couch cushions for loose change. The same reverence for continuous improvement needs to be given to ERPs after its up and running, Carr says.

The reason is simply human nature, Carr explains: Your best workers get placed on this new project for six to nine months, and when the mission is accomplished, they are tired and just want to go back to their normal routines. At the same time, the vendor and consultants vanish from sight as if they're Batman and you're Commissioner Gordon.

"What happens is [these ERP customers] fail to do the continuous improvement on the new technology, therefore they don’t achieve all of the things they really could," Carr says

It starts with change management and some pretty telling conversations Carr has had. Here's a general idea:

Carr asking about a certain process: "Why do you do it that way?"

Manufacturer: "That's the way we've always done it."

Carr: "Why?"

Manufacturer: "Because of Bill. He implemented it 10 years ago."

Carr: "Where's Bill?"

Manufacturer: "He's gone. He left three years ago."

Carr: "Then why do it that way? It doesn’t make any sense. Let's look at some different approaches that are better practices."

[End Scene]

The top two reasons respondents of the survey gave for their project exceeding expectations were support and commitment from top management at 62% and good organizational change management at 48%.

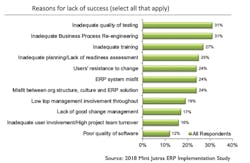

Meanwhile, a quarter of those who had only partial success attributed the users' resistance to change, and 17% determined lack of good change management. Inadequate quality of testing (31%) and inadequate business process re-engineering (31%) were top reasons.

In these cases, changes may have caused the failure to achieve better results, though don’t blame the code.

"What you don’t see is that the software fails," Carr says. "It’s when people go out and try to make changes and make it do something it wasn't designed to do, that's where they run into problems."

Finding unique ways to make the ERP digest and direct sales commissions or pricing the way your company is used to, as opposed to how the ERP is set up, overcomplicates things and takes the focus away from driving those aforementioned improvements.

You just have to have some faith in the plan.

"These projects are not impossible," Carr says. "They are not that hard. Don't step back because everyone is failing, because they're not."

About the Author

John Hitch

Senior Editor

John Hitch writes about the latest manufacturing trends and emerging technologies, including but not limited to: Robotics, the Industrial Internet of Things, 3D Printing, and Artificial Intelligence. He is a veteran of the United States Navy and former magazine freelancer based in Cleveland, Ohio.

Questions or comments may be directed to: [email protected]