Energy Management Can Bring Significant Savings

Energy management is becoming a key element of overall business strategy as industrial companies increasingly focus on optimizing energy costs, achieving environmental, social and governance (ESG) goals and strengthening reliability. In the Deloitte 2021 Industrial Grid Interaction Survey, manufacturing executives cited power outages due to weather-related incidents as their biggest concern. At the same time, industrial executives continue to find ways to reduce their energy costs. In the Deloitte 2020 Resources Study, 48% of industrial respondents identified the desire to cut costs as the primary driver of their decision to implement energy management programs.

For industrial businesses, three converging trends are creating an opportunity for greater grid interactivity of assets. First, a move toward Industry 4.0—the digital transformation of manufacturing processes and products. Second, the electrification of industrial fleets, processes, and space heating and cooling in industrial establishments. And finally, energy management, which primarily involves tracking and optimizing energy use to save costs, reduce carbon emissions, and increase resilience.

Deploying Distributed Energy Resources

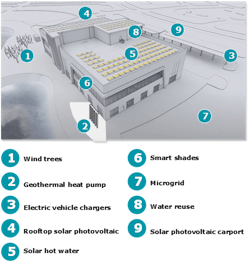

To help industrial businesses achieve their energy management goals, distributed energy resources (DER) are playing a key role. Industrial companies are increasingly considering onsite resources that range from combined heat and power systems to more recent onsite solar or wind energy system installations, battery storage, microgrids, building-level nanogrids, or electric vehicle (EV) chargers. The Smart Factory @ Wichita is an example of a greenfield manufacturing facility that takes advantage of DER (see Figure 1).

Figure 1: Energy management and distributed energy resources at The Smart Factory @ Wichita

A decline in costs of technologies such as solar, wind, and battery storage; favorable government incentives; and growing awareness among industrials could further accelerate DER adoption. In the Deloitte 2021 Industrial Grid Interaction Survey, 50% of manufacturing executives believe the regulatory environment and government incentives are likely to help drive the adoption of renewable energy. New policies designed to enable DER participation in wholesale energy markets could make DER adoption even more attractive for industrial businesses.

Challenges Remain

Energy management solution—such as deploying a building management system (BMS) and installing solar-plus-storage—can help industrial companies meet their energy management goals. For example, a BMS has an estimated useful life of about 10 years and could result in more than 10% net savings in annual electricity costs. Similarly, a solar-plus-storage system, which can be installed, maintained, and operated by the provider, is estimated to yield about 12% in net savings in annual electricity costs. Apart from increasing resiliency, installing a storage system can also help industrial companies draw and store electricity from the grid during cheaper, off-peak hours for use during more expensive, peak hours.

However, as industrial companies pursue opportunities to increase grid interactivity, a few challenges need to be addressed:

- Understanding their current electricity needs

- Building a comprehensive strategy to manage and optimize energy usage and assets

- Effectively identifying, managing, and navigating cyber risks.

Creating a Plan

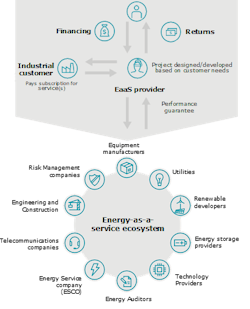

While industrial companies have a number of opportunities to realize the full potential of implementing energy management solutions, participation levels remain low due to high capital investment costs and limited availability. Creating a smart energy management plan and bringing multiple ecosystem players together could be a starting point for industrial companies. For example, forming alliances with technology platform providers, equipment suppliers, renewable energy developers, traders and others could be one means for industrials to navigate this market. Increasingly, that ecosystem participation could include “Energy-as-a-service” (EaaS), a turnkey delivery model that combines installation, ownership, and operations and maintenance of onsite renewables, storage, and other DER.

These services may also be packaged with financing, renewable energy credits and participation in available utility market programs and bundled solutions from a growing ecosystem of players.

Figure 2: Energy-as-a-service ecosystem

The drive to reduce energy costs and achieve ESG targets are among the converging trends that will likely accelerate industrial companies’ adoption of energy management solutions. Other trends such as the rapidly falling costs of solar, wind, and battery storage technologies could also play a role, along with favorable government incentives. The expanding ecosystem of providers offering simplified OpEx-funded Energy-as-a-Service solutions may reduce industrial companies’ concerns over energy expertise or capital budgets. These collective factors may spur industrial companies to get increasingly connected and interactive in their energy management.

Paul Wellener is a vice chairman and U.S. industrial products & construction leader at Deloitte LLP.